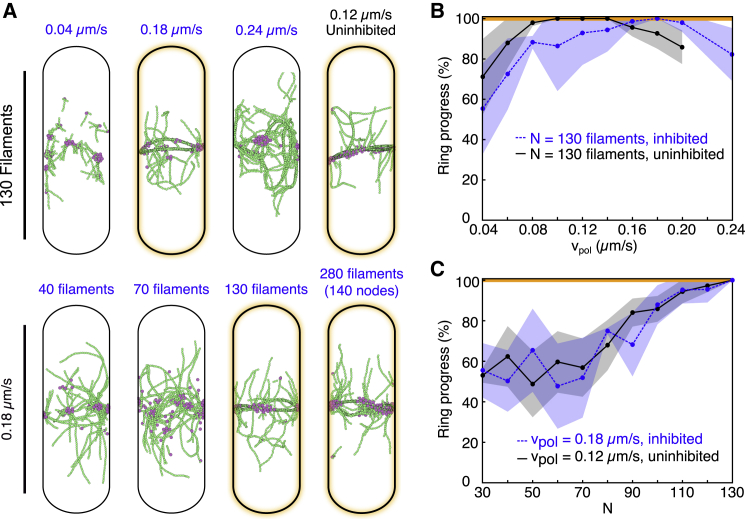

Figure 2.

Ring assembly depends more strongly on formin nucleation efficiency than polymerization rate. (A) Snapshots at t = 800 s of simulations at different values of vpol and N. Upper: snapshots at a constant nucleation efficiency, N = 130, depict nonring morphologies resulting from too low or too high of polymerization rates, as well as proper ring formation for intermediate values (orange highlight). In the absence of formin mechanoinhibition, low polymerization rates (right) resemble higher elongation rates with inhibition. Lower: snapshots at a constant polymerization rate, vpol = 0.18 μm/s, depict a progression to more favorable conditions for ring assembly with increasing N. Outcomes of simulations using 65 nodes are comparable with those of equivalent simulations using 140 nodes (right, vpol = 0.2 μm/s). Video S2 shows simulations evolving in time. (B and C) Dependence of ring progress (see Materials and methods) on key parameters in which 100% corresponds to a fully formed ring (orange line). Data points are averages of three to seven independent runs and shaded regions represent standard deviations. Two-dimensional heat maps are shown in Fig. S2. (B) At a constant nucleation efficiency, N = 130, progress toward ring assembly exhibits a gradual dependence on polymerization rate, vpol, with many conditions supporting complete ring assembly. Peak values are shifted to higher vpol with formin mechanoinhibition. (C) At a constant polymerization rate that favors ring assembly, ring progress increases drastically at high nucleation efficiency for both inhibited and uninhibited formins.