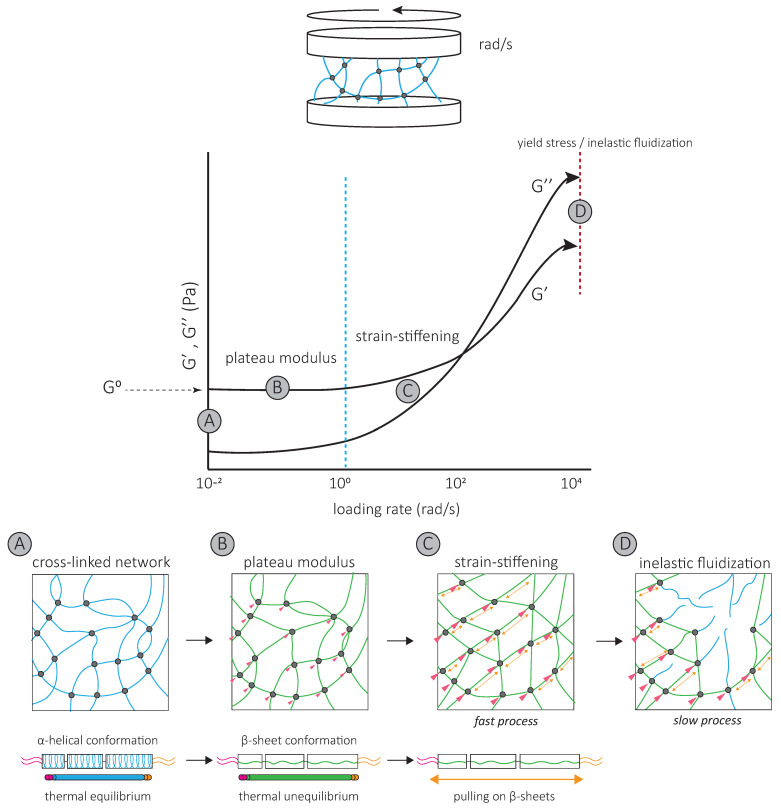

Figure 4.

The mechanical properties of IF networks characterized by oscillatory shear rheology experiments of in vitro assembled networks (A). Deformation of the network using oscillatory shear rheology is achieved by network assembly between two plates and rotating one plate while the other is fixed, inducing a controlled deformation. Increasing the frequency of the rotations (rad/s) increases the stress and strain applied to the network. The response of the IF network to oscillatory shear is viscoelastic. Within the range of 0.01 and 10 rad/s, G’ and G’’ are independent of the oscillatory frequency, and a plateau is observed in both the G’ and G’’ curves. The corresponding G’ is called the plateau modulus or G0 (B). Further increasing the stress by increasing the oscillatory shear frequency results in strain-stiffening of the network ((C), start is indicated with blue dotted line). The network strain-stiffens up to a critical stress, the yield stress ((D), red dotted line), at which the network ruptures. This corresponds to the start of inelastic fluidization. The plateau modulus results from attractive forces between filaments (grey circles) to maintain the stretched β-sheet conformation of single filaments between crosslinks which are in thermal unequilibrium ((B), green filaments). The weaker inter-filament interactions between filament rod domains are thought to be responsible for the attractive interactions at low loading rates. Lower forces are required to resist the lower stresses (pink). Strain-stiffening results from the stretching of single filaments in β-sheet conformations ((C), yellow arrows) maintained by stronger inter-filament interactions. C-terminal tails of IFs are thought to be responsible for these inter-filament attractive interactions, which have to resist high stresses (pink). At the critical yield stress, the network ruptures as a result of the unbinding of multiple crosslinks (D). Strain-stiffening and inelastic fluidization compete at high stresses, resulting in a loading-rate-dependent rupture of the network [72]. Strain-stiffening is a fast process (C) while inelastic fluidization is slow (D). At fast loading rates, strain-stiffening dominates, and the network can resist higher stresses. At slow loading rates, the unbinding of crosslinks has time to occur within the same time frame as strain-stiffening, resulting in rupture of the network at lower stresses.