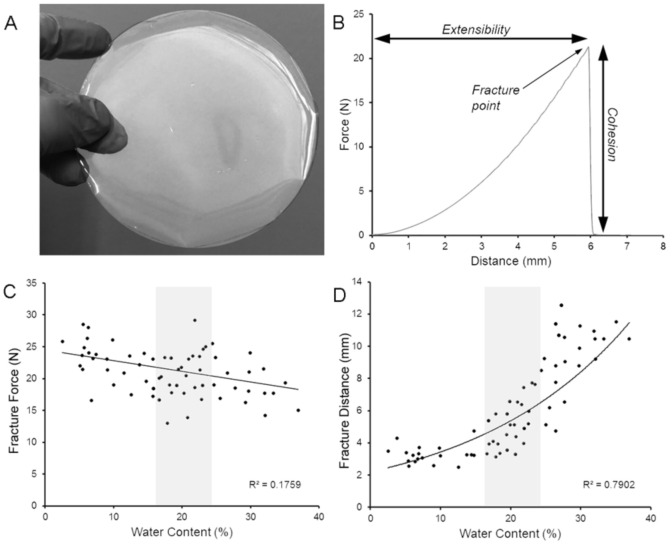

Figure 1.

Physical properties of pectin films used for bowel adhesion. (A) The pectin films were poured into a custom mold prior to curing. The films were translucent and flexible. (B) As previously described [32], burst testing was performed with a stainless-steel spherical probe that descended at a velocity of 0.5 mm/s until film rupture (fracture point). Continuous force and distance measurements were recorded at 500 points per second (pps). Burst testing provided a measure of pectin cohesivity (C) and extensibility (D) at various water concentrations. The pectin films used in this study were selected with intermediate physical properties (gray rectangle).