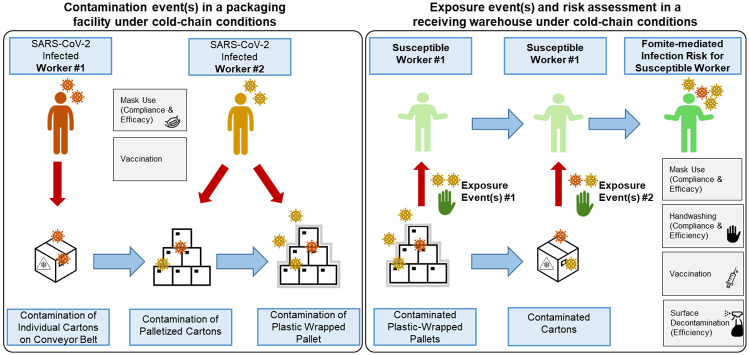

Figure 1.

Conceptual framework for fomite-mediated SARS-CoV-2 transmission involving exposure of a susceptible worker to individual plastic cartons, palletized cartons, and plastic wrap in a receiving warehouse under cold-chain conditions. This schematic depicts a representative frozen food packaging facility, initiating with two infected workers (left panel). Up to 10 contamination events per infected worker (0 to 10 coughs) can occur at three stages in the packaging pipeline: 1) contamination of the top-face of individual plastic cartons (144-216 individual cartons processed per hour) via respiratory droplet and aerosol fallout from the first infected worker while cartons are transported along a conveyor belt (orange in schematic); 2) contamination of cartons via respiratory particle spray (droplets and aerosols) as cartons are placed (manually or via automation) on a pallet by the second infected worker (yellow in schematic); and 3) contamination of the plastic-wrapped palletized cartons by respiratory particle spray (droplet and aerosol) from the second infected worker (yellow in schematic). Four pallets, each containing approximately 36-54 individual plastic cartons, are processed per hour. Because of current Good Manufacturing Practices (cGMP), the model did not account for indirect transfer of virus from the infected workers’ hands to the plastic fomites along the packaging pipeline. Under cold-chain conditions assuming no viral decay, plastic wrapped pallets were transported to a receiving warehouse for unloading by a susceptible worker. Infection risks resulting exclusively from fomite transmission were simulated as contacts between the susceptible worker’s fingers and palms (of both hands) and the fomite surface (accounting for the surface area of the hand relative to the fomite surface); virus transfer from fomite to hands; and virus transfer from fingertips to facial mucous membranes (accounting for the surface area of the fingers relative to the combined surface area of the eyes, nose, and mouth). Grey boxes indicate infection control measures implemented for the infected (mask use, vaccination) and susceptible (handwashing, mask use, vaccination) workers. In the scenarios with additional plastic surface decontamination, this was simulated prior to the susceptible worker contacting the fomites.