Abstract

Hydrogels have been widely investigated in biomedical fields due to their similar physical and biochemical properties to the extracellular matrix (ECM). Collagen and hyaluronic acid (HA) are the main components of the ECM in many tissues. As a result, hydrogels prepared from collagen and HA hold inherent advantages in mimicking the structure and function of the native ECM. Numerous studies have focused on the development of collagen and HA hydrogels and their biomedical applications. In this extensive review, we provide a summary and analysis of the sources, features, and modifications of collagen and HA. Specifically, we highlight the fabrication, properties, and potential biomedical applications as well as promising commercialization of hydrogels based on these two natural polymers.

Keywords: Microstructure, Fabrication, semi-interpenetrating network, dynamic properties, extracellular matrix

1. Introduction

Hydrogels are crosslinked networks of hydrophilic polymers with high water content that have been studied and used clinically for many decades. They have been used extensively to investigate the interactions of cells with their microenvironment and as scaffolds for biomedical and tissue engineering applications, such as drug delivery and wound dressings. Among the various polymers available, those derived from natural biological sources add significant bioactivity and thus are widely used [1–3].

Native ECMs are mainly composed of proteins, glycosaminoglycans (GAGs), which are polysaccharides that often bind covalently to a protein backbone to form proteoglycans [4]. Collagen is the most abundant protein in the ECM and in mammals [5]. Cells interact with collagen via various cell surface receptors such as integrins [6]. Collagen can be degraded by matrix metalloproteinases, which play an important role in the remodeling of the ECM and the development of tissues [7]. Collagen can be sourced from a variety of animals and tissues and is thus widely available for research and clinical applications. To overcome batch-to-batch variability and possible immunogenicity of animal-derived collagen, recombinant collagen has been explored as another source to mimic human collagen [8,9]. Collagen-based hydrogels have been fabricated through the self-assembly of collagen fibrils or by adding chemical crosslinking reagents. However, potential modifications of collagen are limited by both the complexity of its structure and biocompatibility requirements. Commercial applications of collagen matrices include wound repair, skin healing, and orthopedic regeneration (see Section 3.3) [10].

HA is a highly hydrated GAG distributed in the ECMs of various types of tissues and is important for diverse biological processes and tissue functions (see Section 2.2). The different functional groups in HA contain carboxyl, hydroxyl, and acetyl groups, which enable chemical modifications [11] that can alter the properties of the resulting material. HA-based hydrogels are biocompatible, have tunable properties, and mainly interact with CD44 membrane receptors found on many cell types. Consequently, the design, fabrication, and biomedical application of HA-based hydrogels have been widely pursued in recent years [12].

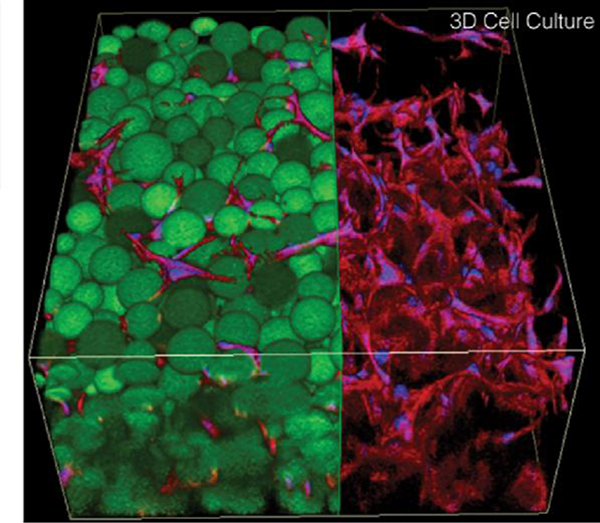

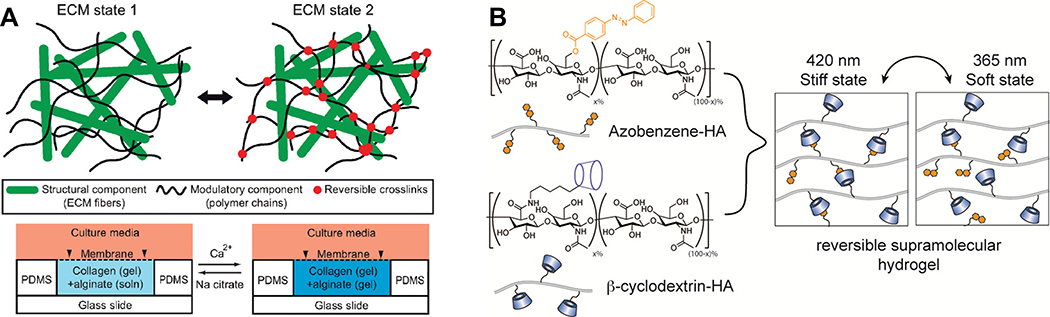

Hydrogels containing collagen and HA combine the features of these two ECM components to mimic the ECM in both structure and function. In physically crosslinked collagen and HA blend (ColHA) hydrogels, collagen molecules aggregate due to electrostatic and hydrophobic interactions to form fibrils, whereas HA can associate with the surface of collagen fibrils or occupy interstitial space and influence the microstructure and viscosity of the hydrogel (see Section 5.1.2) [13–15]. Chemical crosslinking can be used to tailor the properties of ColHA hydrogels (e.g., mechanical properties and microstructure) for applications in vitro and in vivo. In addition to advances in crosslinking chemistry, numerous engineering techniques, such as plastic compression, molding, and bioprinting, have been developed to fabricate collagen- and HA-based hydrogels with tunable stiffness and spatially-defined microstructure [16,17]. The combination of stimuli-responsive chemistries and biofabrication technologies can be used to tailor hydrogel degradation, mechanical strength, and structural patterning to advance applications such as guiding cellular behavior and disease therapy.

The objective of this review is to provide a comprehensive understanding of collagen and HA biopolymers and their use within both individual hydrogels and combined ColHA hydrogels. Although collagen and HA have been reviewed extensively, other review papers have not given much attention to hydrogels that combine both components. In this review, the sources, structures, bioactivities, production, and applications of HA and collagen polymers are summarized (Sections 2 and 3). Current crosslinking and fabrication strategies of collagen, HA, and ColHA hydrogels are discussed in greater detail (Section 4). The regulation of internal fibril and porous microstructure as well as the mechanical properties and dynamic control of ColHA hydrogel properties are discussed (Section 5). Recent applications of collagen- and HA-based hydrogels in tissue engineering, including bone and cartilage regeneration, skin repair, and disease models are described (Section 6). Finally, the future directions of collagen and HA based hydrogels, ranging from control of hydrogel properties to biomedical applications, are considered (Section 7).

2. In vivo roles and functions of collagen and HA

The ECM is an acellular network of macromolecules present within tissues that provides structural support and biomechanical and biochemical cues to the surrounding cells. The ECM is insoluble, which is mainly due to highly cross-linked ECM proteins such as collagens [18], and thus is a stable source of cell signaling molecules. Despite the variation in composition between the ECM of different tissues, all ECMs are composed of three main classes of molecules: proteins, glycoproteins, and proteoglycans. The most abundant fibrous protein found in the mammalian ECM is collagen, which comprises ≤30% of total body protein mass [19]. Proteoglycans are biomacromolecules in which proteins are covalently attached to GAGs. They offer unique buffering, hydrating, and force-resisting properties to the ECM [19]. HA is a unique GAG as it does not contain sulfate, and it does not contain covalently bound core proteins [20]. Instead, HA non-covalently binds to aggrecans though link protein [21,22]. The high viscosity of HA confers resistance to compressive forces and makes it especially important in load-bearing tissues. HA cell receptors regulate functions including induction of chondrogenesis, osteogenesis, neurogenesis, cardiogenesis, and angiogenesis; increasing proliferation of cells including astrocytes and endothelial cells; and controlling inflammation by binding monocytes [23]. In the native environment, collagen and HA create semi-interpenetrating networks [24]. This review will specifically focus on collagen and HA. For a detailed review of glycoproteins, see the 2020 review by Walimbe and Panitch [25].

2.1. Distribution and function of collagen and HA in tissues

2.1.1. Collagen types, properties, and distribution

Collagen refers to a family of proteins defined by their unique structural motif. Each collagen monomer is composed of three polypeptide chains (referred to as α-chains [26]) that self-assemble in a zipper-like fashion to form a collagen monomer, which in turn assembles further into a higher-order supramolecular right-handed triple-helical domain [27,28]. To date, 28 collagen types have been identified. They are designated with Roman numerals I to XXVIII in order of their discovery and are composed of different combinations of at least 46 types of polypeptide chains [27,29]. Collagen monomers composed of the same three polypeptide chains are referred to as a homotrimer, whereas collagen monomers with different polypeptide chains are heterotrimers. The polypeptide chains are composed of a repeated tripeptide motif (GXY)n. Glycine (G), which is sterically small, occurs at every third residue and allows for close packing of the polypeptide chains to form a triple helix about a common axis [6]. The identities of the X and Y residues are dependent on the collagen type; however, Y is often the post-translationally modified residue 4-hydroxyproline [30]. Triple-helical collagenous (COL) domains are interrupted by non-collagenous (NC) domains that confer different biological activities depending on the collagen type [6,31]. The convention for domains typically begins with numbering from the C-terminus of collagen [6]. The number and locations of the NC domains contribute to different supramolecular organization, which determines the function of the collagens [6,32]. Collagens are classified into different subfamilies based on their structure and function. The subfamilies include fibrillar collagens (types I, II, III, V, XI, XXIV, and XXVII), fibril associated collagens with interrupted triple helices (FACIT) and related collagens (types IX, XII, XIV, XVI, XIX, XX, XXI, and XXII), beaded filament-forming collagen (type VI), basement membrane and associated collagens (types IV, VII, XV, and XVIII), transmembrane collagens (types XIII, XVII, XXIII, and XXV), and hexagonal network collagens (types VIII and X) [6,33,34]. Collagen types and their defining characteristics are summarized in Table 1. As fibrillar collagens are the most abundant ECM proteins, they are on the forefront of tissue engineering research and thus will be the focus of this review.

Table 1.

Defining features of collagen types.

| Collagen Type | Subfamily | Molecular Species | Supramolecular Structure and Structural Features | Distributions | Function |

|---|---|---|---|---|---|

| I | Fibril Forming | • [α1(I)]2, α2(I) • [α1(I)]3 |

300 nm molecule, 67 nm banded fibril [35] | Ubiquitous, predominant in skin, tendons, ligaments, bones [35] | Key structural component of tissues [35] |

| II | Fibril Forming | • [α1(II)]3 | Cartilage | Confers tensile strength and elasticity to cartilage [36], endochondral bone formation [37] | |

| III | Fibril Forming | • [α1(III)]3 | Stabilizing C-terminal cystine knot [38] | Dermis, aorta [28], uterus, blood vessels, bowel, wound healing, blood clotting cascade [39] | Tensile strength and integrity [39] |

| IV | basement membrane and associated collagens | • [α1(IV)]2, α2(IV) • α3(IV), α4(IV), α5(IV) • [α5(IV)]2, α6(IV) |

COL domain with 21–26 interruptions [40] | Basement membranes | Cell adhesion, migration, differentiation, growth [41] |

| V | Fibril Forming | • [α1(V)]2, α2(V) • [α1(V)]3 • [α1(V)]2, α4(V) • α3(XI), α1(V), α3(XI) |

Thrombospondin domain [6] | Interstitial tissue [42], dermal-epidermal junction [43] | Regulates collagen fibrillogenesis [44] |

| VI | beaded filamentforming collagen | • α1(VI),α2(VI),α3(VI) | C-terminal propeptide endotrophin hormone [45,46] Much lower frequency of GPO repeat [28] |

Ubiquitous [28], basement membrane-interstitial matrix interface [46] | Maintains the integrity of skeletal muscle [46] |

| VII | basement membrane and associated collagens | • [α1(VII)]3 | Exceptionally long triplehelix domain, Kunitz domain [6] | Epidermal–dermal Junction [6] | Anchoring collagen, binds fibril forming collagens [47] |

| VIII | hexagonal network collagens | • [α1(VIII)]2, α2(VIII) • α1(VIII), [α2(VIII)]2 • [α1(VIII)]3 • [α2(VIII)]3 |

C1q domain [6] | Descemet’s membrane [48], vascular smooth muscle [49] | Mechanical stability of vascular wall, bridge between ECM components [50] |

| IX | FACIT | • α1(IX), α2(IX), α3(IX) | Thrombospondin domain, three COL and three NC domains [6] | Articular cartilage [51] | Stabilizes fibrillar collagen network in the cartilage matrix, anchors matrilin 3 and proteoglycans [52] |

| X | hexagonal network collagens | • [α1(X)]3 | C1q domain [6] | Hypertrophic cartilage [53] | Regulates endochondral ossification of articular cartilage [54,55] |

| XI | Fibril Forming | • α1(XI), α2(XI), α3(XI) • α1(XI), α1(V), α3(XI) |

Thrombospondin domain [56] | Minor component of hyaline cartilage collagen fibrils [57], broadly distributed in testis, trachea, tendons, trabecular bone, skeletal muscle, placenta, lung, and the neoepithelium of the brain [56] | Nucleates and controls cartilage collagen fibril formation [57] |

| XII | FACIT | • [α1(XII)]3 | Largest FACIT collagen, Triple armed NC3 domain [58], two variants [59] NC3 domain carries glycosaminoglycan chains [59] | Mesenchymal tissue during development [60], periodontal ligament [61], dermis around hair follicles [62], cornea of the eye [63] in adults | Temporarily stabilizes collagen fibrils during development [59,60,64] |

| XIII | transmembrane collagens | • [α1(XIII)]3 | Connective tissue, blood vessel and junctions [65] | Bone formation [66], regulates formation of neuromuscular synapse [67] | |

| XIV | FACIT | • [α1(XIV)]3 | Skin, tendon, cornea, articular cartilage [68] | Fibrillogenesis regulation, Maintaining mechanical integrity [68], embryonic development [60] | |

| XV | basement membrane and associated collagens | • [α1(V)]3 | Bonded to chondroitin sulfate via disulfide-bonds [69] Flexible due to knot/figure-of-eight/pretzel configuration [70] Thrombospondin domain [6] |

Cardiac and skeletal muscles, basement membrane zones [71] | Maintains integrity of ECM [71] |

| XVI | FACIT | • [α1(VI)]3 | Flexible due to kinks in structure, 10 COL and 11 NC domains [72–74] | Territorial cartilage matrix [74,75], integrated into fibrillin-1-rich microfibrils containing in skin [74] | Hypothesized to stabilize ECM by organizing and connecting fibrillar networks, cell adhesion and invasion [72,76] |

| XVII | transmembrane collagens | • [α1(XVII)]3 | 15 COL and 16 NC domains [6] | Basement membrane zone, specifically hemidesmosomes [77,78], central nervous system neurons [79] | Epidermal cell adhesion [80] Proliferation of epidermis [81] |

| XVIII | basement membrane and associated collagens | • [α1(XVIII)]3 | Thrombospondin domain, 10 triple helical COL domains 11 NC domains [6] | Basement membrane zones [82] | Eye development [83], maintaining basement membrane integrity [84] |

| XIX | FACIT | • [α1(XIX)]3 | Thrombospondin domain [6] | Vascular, neuronal, mesenchymal, epithelial basement membrane zones [85], hippocampal neurons [86] | Affects the phenotype for smooth muscle motor dysfunction and hypertension sphincter [87] |

| XX | FACIT | • [α1(XX)]3 | von Willebrand factor A, fibronectin type III repeat, thrombospondin domain [6,88] | Possibly bile ducts, breast, cerebellum, smooth muscle cells [89] | |

| XXI | FACIT | • [α1(XXI)]3 | two collagenous domains interrupted by three noncollagenous domains [6,90] | heart, stomach, kidney, skeletal muscle, placenta [90] | May play a role in blood vessel assembly [91] |

| XXII | FACIT | • [α1(XXII)]3 | Does not directly polymerize with fibrillar collagens, but rather associates with components of microfibrils such as fibrillins [92] | Tissue junctions: myotendinous junctions, articular cartilage-synovial fluid junction, border between the anagen hair follicle and the dermis in the skin [92] | Possibly mechanical stability of myotendinous junctions [92] |

| XXIII | transmembrane collagens | • [α1(XXIII)]3 | N-terminal cytoplasmic domain, a transmembrane domain, and extracellular triple helical domains [93] | Lung, cornea, skin, tendon, amnion [94] | Cancer, cell-cell and cell-matrix adhesion mediation [95] Expression elevated in prostate cancer recurrence and distant metastases [96] |

| XXIV | FACIT | • [α1(XXIV)]3 | Thrombospondin-Nterminal like motif and charged segments with tyrosine residues on amino-terminal domain [97] | Bone and cornea [97] | Marker of osteoblast differentiation and bone formation [98] |

| XXV | transmembrane collagens | • [α1(XXV)]3 | COL domain interrupted four times (two four-residue imperfections and two large NC sequences) [99] | Neurons predominantly of brain, also of heart, testis, eye [100–102] | Also known as collagen-like amyloidogenic component, isolated from Alzheimerdiseases brains, component of amyloid plaques [99] |

| XXVI | Not assigned | • [α1(XXVI)]3 | Two collagenous regions and no obvious sequence homology [103] | Testes, ovary [103] | Testis and ovary development [103] |

| XXVII | Fibril Forming | • [α1(XXVII)]3 | Nonstriated fibrils, 10 to 80 nm fibril width [104,105] | Adult cartilage [106] | Cartilage calcification, possibly cartilage transition to bone [107] |

| XXVIII | Not assigned | • [α1(XXVIII)]3 | 528 amino-acid collagenous domain flanked by two von Willebrand factor A [6,108] Structurally resembles collagen VI |

Basement membranes of peripheral nervous system [109,110] |

2.1.1.1. Fibrillar collagens

Fibrillar collagens are ubiquitous throughout the ECM space of tissues and are most abundant in bones, blood vessels, skin, tendons, and fibrous capsules of organs [111,112]. The ability of the protein to self-assemble into fibers confers mechanical strength and provides a structural framework for tissues and organs. The formation of fibrillar collagens in vivo is reviewed by Kadler [113]. Briefly, cells secrete thin collagen fibrils into the ECM via fibripositor projections from the plasma membrane. Fibrillar collagen assembly is heavily regulated in the body by cellular and tissue-specific stimuli and results in widely varying collagen fibril architectures from aligned bundles in tendons to woven matrices in skin.

The fibrillar collagen family can be further subdivided into the major fibril-forming collagens, which consist of type I, II, and III, and minor fibril-forming collagens, which are composed of types V and XI [114]. Major fibrillar collagens are the main structural components of the ECM and are supplemented by the minor fibrillar collagens. The amino acid sequences of the α-chains of minor fibrillar collagens share a high degree of similarity with major fibrillar collagens with the exception of variable region domains caused by alternative splicing of the proteins [114]. The function of minor fibrillar collagens is not yet fully understood; however, the manifestation of diseases associated with their mutations highlight their importance. For an in-depth review on minor fibrillar collagens, refer to the 2012 review paper by Fang and coworkers [114].

In fibrillar collagen, the X position of the GXY motif is commonly proline (P). The Y position of the GXY motif is typically 4-hydroxyproline (O), which is post-translationally modified proline (P) [115], or lysine, which is post-translationally modified to hydroxylysine [116]. In human collagen, proline and lysine are 42–54% and 13–28% hydroxylated, respectively [117,118]. Hydroxyproline is an imino acid predominantly found in collagens, which contain 99.8% of the body’s hydroxyproline content [119]. The GPO triplet is the most frequently observed amino acid sequence in collagen and comprises ~10.5% of the collagen content [120]. Each of the amino acids in the triplet contributes to the supramolecular structure. Glycine enables a packed structure of the collagen monomer chains, which is stabilized by intramolecular hydrogen bonding and electron-withdrawing effects of hydroxyproline [115]. Proline provides local conformational flexibility, which enables low energy molecular compression, extension, and bending [121]. The hydroxyl groups of 4-hydroxyproline stabilize the collagen triple helix. Nearly complete hydroxylation of the prolines in the Y position is necessary for the formation of collagen that is stable at 37 °C [30]. The Brodsky group elucidated this stabilizing effect of the triple helix by varying the amino acids in the guest X and Y positions in collagen mimetic peptides (CMPs) containing GXY repeats (Table 2) [122]. The sterically hindered proline and hydroxyproline imino acids in collagen, combined with the small glycine residue, result in bending and twisting of individual monomer chains to form left-handed polyproline-II helices [27]. Adzhubei and colleagues provide an in-depth review on proline-II structure, properties, and physics [123]. Three polyproline-II helices self-assemble into a right-handed helix that comprises the procollagen molecule (Fig. 1a). The importance of charged amino acids in triple helix formation is summarized in a review by the Kiick group [124]. CMPs and collagen-like proteins from bacteria have been used to understand collagen triple helix formation and how to meet or exceed helical thermal stability [124,125] by replacing hydroxyproline with non-canonical amino acids such as fluoroproline and chloroproline [126–128], incorporating electrostatic interactions of oppositely-charged residues either within or between a tri-peptide chain repeat [129–137], and using numerous other methods [9].

Table 2.

a Amino acids impart varying levels of thermal stability, measured as melting temperature (Tm), in the X and Y guest residue positions of the CMP triple helix.

| Guest Residue | Gly-X-Hyp Tm (°C) | Gly-Pro-Y Tm (°C) |

|---|---|---|

| Pro | 47.3 | - |

| Hyp | - | 47.3 |

| Glu | 42.9 | 39.7 |

| Ala | 41.7 | 40.9 |

| Lys | 41.5 | 36.8 |

| Arg | 40.6 | 47.2 |

| Gln | 40.4 | 41.3 |

| Asp | 40.1 | 34.0 |

| Leu | 39.0 | 31.7 |

| Val | 38.9 | 40.0 |

| Met | 38.6 | 42.6 |

| Ile | 38.4 | 41.5 |

| Asn | 38.3 | 30.3 |

| Ser | 38.0 | 35.0 |

| His | 36.5 | 35.7 |

| Thr | 36.2 | 39.7 |

| Cys | 36.1 | 37.7 |

| Tyr | 34.3 | 30.2 |

| Phe | 33.5 | 28.3 |

| Gly | 33.2 | 32.7 |

| Trp | 31.9 | 26.1 |

Adapted with permission from A.V. Persikov, J.A.M. Ramshaw, A. Kirkpatrick, B. Brodsky, Biochemistry 39 (2000) 14960–14967 [122]. Copyright 2000 American Chemical Society.

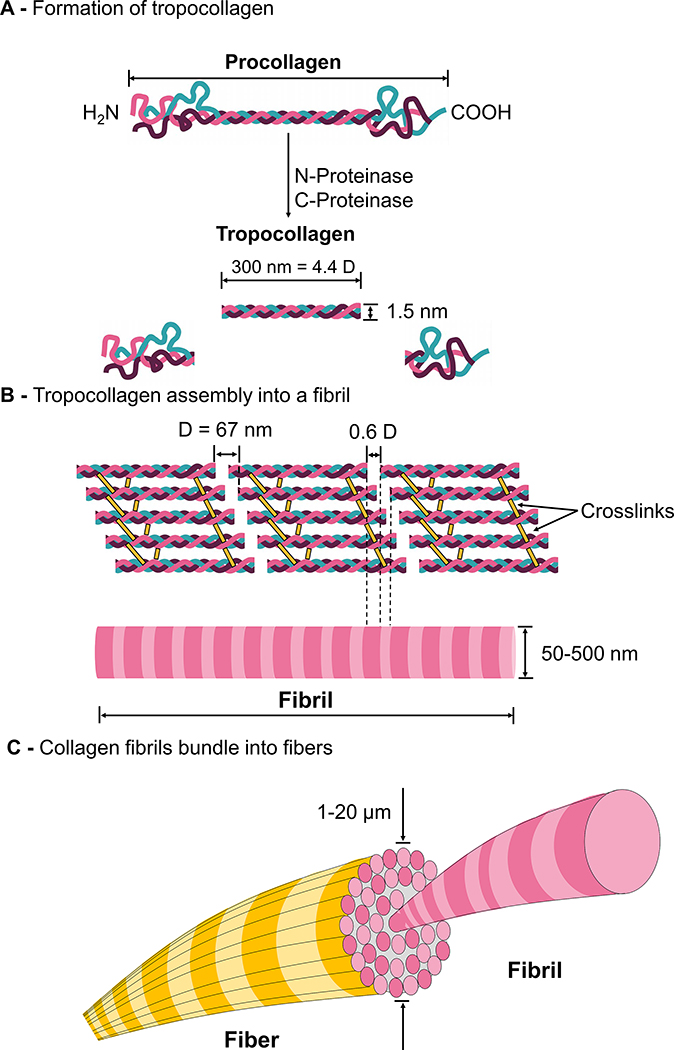

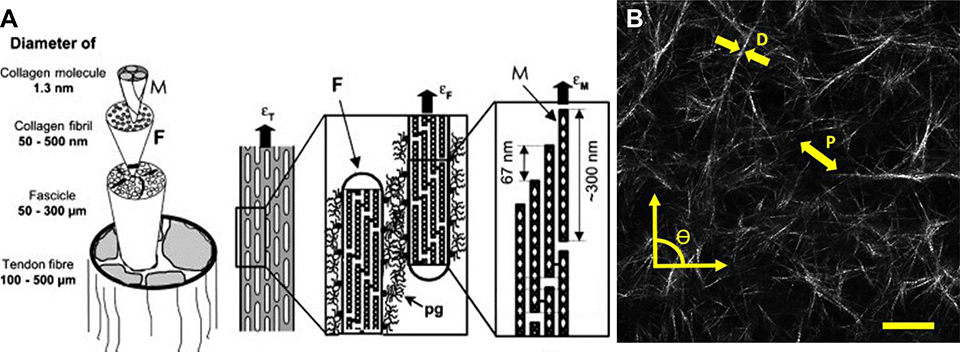

Fig. 1.

Molecular structure and synthesis of collagen I. (A) Following intracellular post translational modifications, three polypeptide chains assemble into procollagen, which is then exocytosed into the extracellular space. N-proteinase and C-proteinase cleave the ends of procollagen to form tropocollagen. (B) Collagen I tropocollagen is 300 nm (corresponding to 4.4 D) in length and 1.5 nm in diameter. Tropocollagen molecules self-organize and crosslink to form collagen fibril with periodicity of D, which is typically 64–67 nm. (C) Collagen fibrils bundle to form fibers.

Despite the recurrence of the stabilizing GPO amino acid sequence, irregularities in the X and Y residues are essential for biological specificity and function [130]. Hydroxylysine serves as a substrate for O-linked glycosylation, which allows for crosslinking of collagen [33]. The degree of glycosylation affects the packaging of mature molecules into fibrils, and increased glycosylation decreases fibril diameter.

The biosynthesis pathway of fibrillar collagen has been studied in great detail and has been extensively reviewed by Bornstein in 1974 [138]. Briefly, fibrillar collagen synthesis begins with synthesis of procollagen precursors that contain NC regions on either end. After post-translational modifications, including the formation of hydroxylysine, 4-hydroxyproline, and the glycosylation of hydroxylysine [116], disulfide bonding occurs between polypeptide chains that compose the monomer. Next, the proteins begin to assemble from the C-terminus by twisting tightly towards the left and propagating toward the N-terminus to form procollagen (Fig. 1A). The procollagen molecules are secreted into the ECM [33] upon which the globular N- and C-termini are cleaved off to form tropocollagen. The tropocollagen is approximately 300 nm long and has a diameter of 1.5 nm [35].

On the macromolecular level, five tropocollagen molecules arrange head-to-tail into parallel structures directed by electrostatic and hydrophobic interactions and form a microfibril, the basic subunit of a collagen fibril (Fig. 1B) [35,139]. During this process, lysine and hydroxylysine undergo oxidative deamination into reactive aldehydes that participate in spontaneous crosslink formation between the tropocollagens, and the result are collagen fibrils [30,140]. The distance between two staggered tropocollagen molecules is 64–67 nm (Fig. 1B) [35]. This distance comprises the overlap (distance tropocollagens are staggered by) and gap (distance between two adjacent tropocollagen molecules). This measurement of 64–67 nm is termed distance D, and other dimensions on the collagen molecule are listed in terms of D [35]. The tropocollagen molecules are 4.4 D in length, and the gap between the ends of two adjacent nonoverlapping tropocollagen molecules is 0.6 D. Thus, this regular parallel structure with gaps confers fibrous collagens their signature banded appearance that can be observed via electron microscopy. The gap appears as the dark region of the negatively stained TEM images of collagen fibrils, whereas the overlap region appears as a lighter band due to inability of the stain to penetrate into the region [113,141]. These microfibrils further associate to form fibrils with diameters that range from 50 to 500 nm depending on the tissue [13]. Fibrils bundle into fibers that are 1–20 μm in diameter (Fig. 1C) [142].

2.1.1.2. Most abundant fibrillar collagens

Collagen I is the most abundant fibrillar collagen and makes up 70% of total collagen [112]. It is primarily found in skin, ligaments, bones, and tendons but is ubiquitous throughout the body. Collagen I has two structural variations. The most abundant variant consists of two identical polyproline-II chains α1(I) and one α2(I) chain (heterotrimeric). A smaller portion of collagen I consists of homotrimers with three α1(I) chains [32]. Collagen V is a minor fibrillar collagen often associated with collagen I [28]. For a detailed review on collagen I, including splicing, regulation, and transcriptional regulation, see the 2002 review by Rossert and Brombrugghe [35].

Collagen II is the major constituent of hyaline cartilage, where it constitutes approximately 90% of the total collagen [143]. It is also the major collagen of vitreous humor and nucleus pulposus of intervertebral discs [34]. Other locations include the tendon, retina, sclera, the lens of the eye, notochord, heart, and brain [28,144,145]. Collagen II is a homotrimeric molecule composed of [α1(II)]3 chains [6]. Nearly half of the hydroxylysine residues on collagen II are glycosylated, compared to only 2 residues per chain in collagen I [28,146]. The glycosylation is hypothesized to affect fibril regulation and lateral growth [28]. Collagen XI is a minor fibril forming collagen associated with collagen II. Collagen XI regulates fibrillogenesis by maintaining the spacing and diameter of collagen II fibrils [147].

Collagen III constitutes more than half of the total collagen and >20% of adult skin [148]. It is a homotrimer that is synthesized from three α1(III) chains [6]. Collagen III accompanies collagen I in almost every tissue in different ratios [28]. The protein confers structural integrity to hollow organs that must withstand stretching, including arteries, uterus, and bowel [39].

2.1.1.3. Other Collagen Sub-Families

FACIT are a family of collagens that do not themselves form fibrils but instead bind in regular intervals to the surface of fibril-forming collagens [6]. They are characterized by the presence of NC domain interruptions in the COL domain and the cystine-containing motif GXCXXXC [149]. By incorporating into the interfibrillar space of fiber-forming collagens, FACIT collagens alter surface properties and fibril assembly. They are believed to be involved in fibril-fibril interactions, as well as fibril interactions to other macromolecules present in the ECM.

Other types and families of collagens are less understood and an area of active research. Table 1 summarizes key features of the aforementioned collagens along with other collagen types not discussed here. For an in-depth discussion of other types of collagens, see the 2010 review by Bachinger et al. [28].

2.1.1.4. Collagen Degradation

Collagen is broken down by matrix metalloproteinases (MMPs) into small soluble peptides and amino acids. MMPs are zinc-dependent endopeptidases and typically require calcium as a cofactor [6,7]. MMPs were originally named for the substrates they were observed to degrade [150]. For example, MMP1, MMP3, and MMP8 are known as collagenases, and MMP2 and MMP9 are known as gelatinases. However, MMPs are capable of degrading more than their corresponding substrate [150]. Fibrillar collagens (I, II, and III) are degraded by MMP1, MMP2, MMP8, MMP13, and MMP14 [6,151]. MMP1 and MMP8 favor collagen I and collagen III, whereas MMP13 preferentially cleaves collagen II. Denatured collagens and collagen IV are degraded by MMP2 and MMP9. Collagens are broken down starting from the exterior of triple helices by these MMPs [7]. Collagen fragments are further degraded by gelatinases and nonspecific proteases [7,151]. Under physiological conditions, collagen in its triple helical form is largely not degraded by common proteases such as pepsin, trypsin, and papain [7,152].

2.1.2. HA properties and distribution

HA is an anionic, linear GAG primarily found in the ECM of soft connective tissues. Unlike other GAGs, HA is non-sulfated and does not covalently bind to a core protein to form a proteoglycan [153]. HA forms non-covalent bonds with aggrecan, and these bonds are stabilized by the link protein [21,22]. The molecular weight (MW) of HA in the human body typically ranges from 10 [154] to 8000 kDa [155], whereas other GAGs are typically between 15 to 20 kDa [153]. The different MW of HA confers various biological and biomechanical functions.

The term “hyaluronic acid” was created by Meyer and Palmer, who successfully extracted the compound from cattle vitreous humor, and subsequently named it hyaloid (meaning vitreous) and uronic acid (Fig. 2A), one of the sugar molecules that constitutes the polymer [156]. The term hyaluronan was introduced to conform with international polysaccharide nomenclature [157]. The polyanion without its corresponding cation is referred to as hyaluronate. Under physiological conditions, HA occurs in the salt form [158,159].

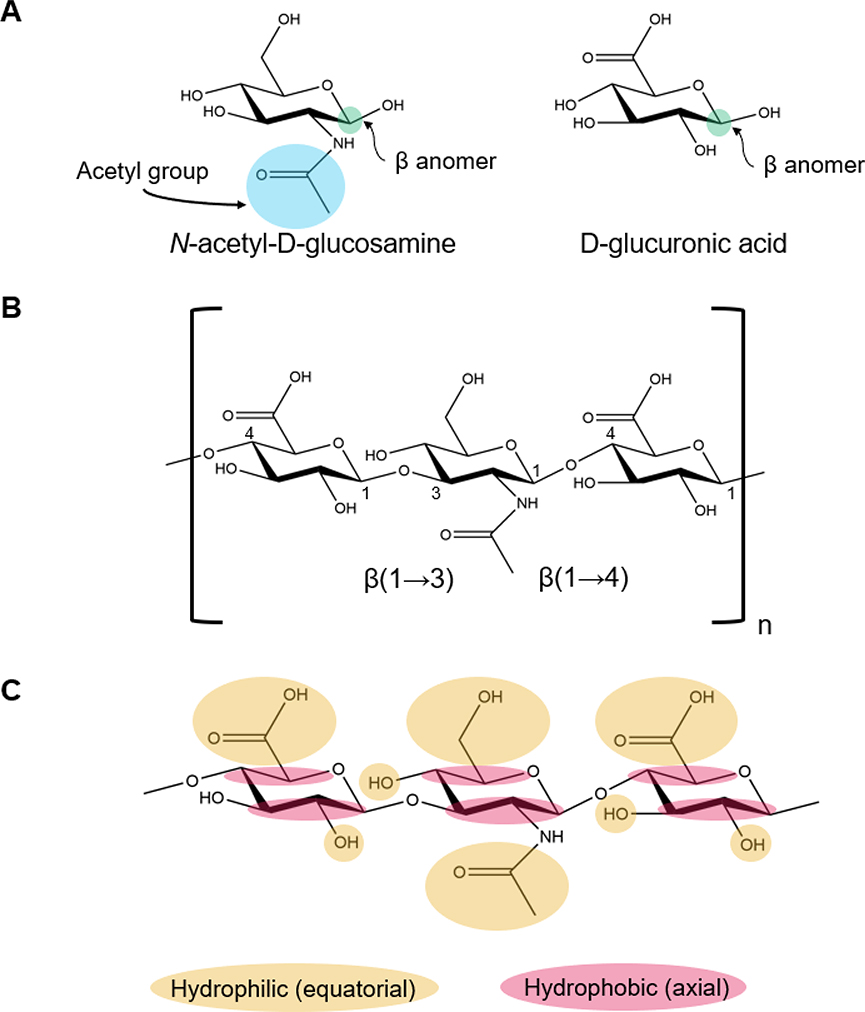

Fig. 2.

Chemical structure of HA and its components. (A) Structures of D-glucuronic acid and N-acetyl-D-glucosamine. (B) Chemical structure of the repeating disaccharide unit of HA linked together by alternating β-(1→4) and β-(1→3) glycosidic bonds. (C) Hydrophilic and hydrophobic moieties, which drive the twisting of the HA molecule, are labeled to show their equatorial and axial positions, respectively.

2.1.2.1. Chemical Structure and Conformation

HA is composed of repeating disaccharide units of D-glucuronic acid (GlcUA) and N-acetyl-D-glucosamine (GlcNAc) (Fig. 2A), which are linked together by alternating β-(1→4) and β-(1→3) glycosidic bonds (Fig. 2B) [160]. The resultant HA polymer is stable because bulky groups are in sterically favorable equatorial positions (Fig. 2C) [158]. The chemical structure of HA is identical across vertebrates and a few pathogenic bacteria that produce it [161,162].

Despite the seeming simplicity of the structure, assessment of the conformation of the molecule and the driving forces behind its molecular conformation is challenging. The natural rigidity of the polysaccharide chain is derived from restrictions on the rotation of the glycosidic bonds due to the bulky N-acetyl groups adjacent to the glycosidic bonds [159]. The conformation of the molecule is highly dependent on the counterion type, pH, temperature, extent of hydration, and, in the case of HA solutions, its concentration [160].

The arrangement of the hydrophobic axial hydrogens and hydrophilic polar equatorial groups drive twisting of the HA structure in solution (Fig. 2C) [158]. The repeating disaccharide provides regularity in spacing and makes twisting into a helical structure possible [159]. The backbone of HA in a physiological solution stiffens due to hydrogen bonding between the hydroxyl groups along the chain and interactions with the solvent [158]. This rigidity results in an extended random-coil configuration [153]. The coils in solution entangle at HA concentrations of 0.5–1 mg/mL and above and thus result in a substantial increase in viscosity [163]. The entangled HA networks create steric exclusions that reduce the mobility of HA and restrict the diffusion and hydrodynamic transport of other substances through the ECM [153]. For a detailed review on HA structure in solution and its physics, refer to reference [160].

2.1.2.2. Properties and Functions

Distinctive viscoelastic properties of hydrated HA confer its unique functionality. The HA polymer has an extraordinary ability to retain up to 1000 times its weight in water [164]. The high water absorption rate confers high viscosity to HA solutions even at lower concentrations [165]. Viscosity and elasticity of the hydrated polymer vary with shear rate, where high shear rate decreases viscosity and increases elasticity, which is the ability to store energy and facilitate recovery from the deformation [153]. The viscoelastic behavior is dependent on the solution conditions, notably the pH, which drastically changes the viscosity of the solution based on the state of entanglement, bonding, and electrostatics [166].

Depending on the MW, HA can influence cell proliferation, migration, morphogenesis, tissue inflammation, tumor development, and tumor metastasis among others [158,167]. HA can be classified into low (10–250 kDa), medium (250–1000 kDa), and high (>1000 kDa) MW HA [168]. High MW HA is found in most tissues and is involved in maintaining the integrity of the ECM, homeostasis, wound healing [169], anti-inflammatory response [170], and cell growth [171]. Low MW HA activates the proinflammatory [172] and macrophage response [173]. It also induces lymphangiogenesis [174] and angiogenesis [175].

2.1.2.3. Distribution in Tissues

HA constitutes about 15 grams of a 70 kg individual [167], and approximately one third of all HA turns over daily [176]. It is present in virtually all human tissues with the highest concentration of HA found in connective tissues [169]. A summary of the concentration distributions and the average MW of HA in various healthy human tissues is in Table 3.

Table 3.

HA concentration and molecular weight in human tissues and fluids.

| Tissue | Concentrationa | Molecular Weight |

|---|---|---|

| Skin (total) | 440–520 μg/g wet weight, mostly in dermis [177] | 2000–5000 kDa [178] |

| Synovial Fluid | 40–3800 μg/mL [179,180] | Majority 6000–7000 kDa [181] |

| Vitreous Body of the Eye | 8–400 μg/mL [182,183] | 2000–4000 kDa [184] |

| Umbilical Cord (Wharton’s jelly) |

20,000 μg/g [185] | 1100 kDa, 700 kDa during acute funisitis (inflammation of umbilical cord), and 520 kDa in necrotizing funisitis [186] |

| Amniotic fluid | 20 μg/mL (16–20th week of pregnancy), 1 μg/mL in the 30th week until the end of pregnancy [187] | 330 kDa (16th week of pregnancy), mixture of >1000kDa and <100kDa (40th week) [188] |

| Aqueous Humor | 1.1 μg/mL [189] | 1000–5300 kDa [190] |

| Lymph Fluid | 0.1–18 μg/mL [191] | 1400 kDa, large range [191] |

| Human Milk | 0.8 μg/mL (immediately postpartum), 0.2 μg/mL (60 days after birth) [192] | 440 kDa [193] |

| Blood plasma | 0.06–0.7 μg/mL[191] | 140–270 kDa [191,194] |

Tissue concentrations are reported in units of μg HA/g of wet weight of the tissue, and fluid concentrations are reported in units of μg HA/mL of the fluid of interest.

2.1.2.4. Synthesis and Degradation

Hyaluronan synthases (HAS) are the enzymes responsible for the production of HA. There are three known isozymes, HAS1, HAS2, and HAS3 [154]. The isoenzymes lengthen the HA polymer by repeated addition of glucuronic acid and GlcNAc groups [154]. Only one of these enzymes is necessary for the production of HA, but their varying kinetics and concentrations result in the production of various MWs [195]. HAS1 and HAS2 are moderately active and produce high MW HA, whereas HAS3 is the most active and polymerizes low MW HA [154]. The presence of certain growth factors, including epidermal growth factors, and cell types, such as keratinocytes, increase HA synthesis. HAS enzymatic activity can be impeded by both mannose [196] and natural antisense mRNA complementary to HAS2 [197].

HA is degraded into monosaccharide components by enzymes, such as hyaluronidases, chondroitinases, and hexosaminidases, as well as by reactive oxygen species (ROS) [198,199]. Two main hyaluronidases, Hyal-1 and Hyal-2, cleave HA in somatic tissues [200]. Hyal-2 degrades high MW HA into intermediate size fragments of ~20 kDa [201]. Inside the cell, the HA fragments are further degraded by Hyal-1 into oligosaccharides (predominantly tetrasaccharides) [202]. The degraded HA fragments and oligosaccharides participate in various signaling cascades described in Section 2.2.2 [202]. There are two classes of enzymes, endo- and exoglycosidases, that cleave larger fragments in the center of the molecule and the termini, respectively [200]. Specifically, hyaluronidases are endoglycosidases that hydrolyze the β−1,4 or the β−1,3 linkage in the center of HA molecules depending on the type of hyaluronidase [200,203]. The oligosaccharide products are further degraded by the exoglycosidases β-D-glucuronidase and β-N-acetyl-glucosaminidase, which remove terminal sugars [200,204,205]. Stern et al. provide a thorough review of HA degradation methods [200].

2.2. Interactions between collagen/HA and cells

Both collagen and HA play major roles in the development and maintenance of the ECM and also provide biochemical and physical cues to cells for functions such as adhesion, proliferation, differentiation, and production or degradation of the ECM. The interaction of collagen and HA with cell surface receptors contributes to matrix remodeling, including the synthesis of new molecules, such as collagen and proteoglycans, and the production of degrading enzymes. Additionally, the degradation of collagen and HA into smaller fragments can trigger other cell responses. Collagen fragmentation can lead to the recruitment of neutrophils, monocytes, macrophages, mast cells, and fibroblasts. Collagen and HA also contribute to the progression and the mitigation of various diseases such as cancer and osteoarthritis [206–208].

2.2.1. Collagen & cells

Collagen interacts with cells largely via various integrin cell surface receptors. Collagen binds to integrins that contain the β1 subunit and one of the following alpha subunits: ɑ1, ɑ2, ɑ10, and ɑ11 [209]. In native collagen, the minimal binding sequence for integrins includes GFOGER and GROGER [6,210,211]. Additional integrins can bind to hidden RGD sites that become available when collagen is denatured [211]. Denatured collagen fragments can also temporarily anchor to the ECM and provide additional sites for cellular migration and adhesion [212]. KGD motifs can also be recognized by RGD-binding integrins but with different affinity than for RGD [210]. Fibrillar collagens have a strong avidity for the ɑ2β1 integrin, which regulates cell adhesion and migration. Collagen binding with integrins is reviewed extensively by Heino et al. [210].

Other surface receptors that collagen interacts with include dimeric discoidin receptors (DDRs), DDR1 and DDR2, glycoprotein VI (GPVI) on platelets, and leukocyte-associated immunoglobulin-like receptor-1 (LAIR-1) on immune cell surfaces [6,207,212]. DDRs can bind to the GVMGFO motif in collagen. DDRs regulate cell functions such as proliferation, differentiation, and matrix maintenance [212]. GPVI and LAIR-1 bind to GPO motifs, which are found on all collagens [210]. GPVI is an important receptor found on platelets, and collagen binding can trigger signaling events and activate the function of platelets during thrombosis. Interactions between LAIR-1 and collagen can downregulate immune responses as LAIR-1 is a surface receptor found on peripheral blood mononuclear cells. Thus, collagen is implicated in numerous autoimmune diseases [207].

NC domains found in collagen offer an additional site for binding to cell surface receptors and thus play a pivotal role in numerous cellular processes. For example, NC1 in various collagens (e.g., Col IV, Col XVIII) interacts with integrins on endothelial cells (ECs) and inhibits angiogenesis [213]. The importance of NC domains in the molecular architecture of the ECM and its biological functions are highlighted by Ortega and coworkers [214].

2.2.2. HA & cells

HA interacts with cells in numerous pathways through surface receptors to initiate cell functions. CD44 is the primary class of cell surface receptors that interact with HA [206]. CD44 is a transmembrane glycoprotein found throughout the body on numerous cell types, such as leukocytes, fibroblasts, mesodermal cells, and cancer cells [215]. HA interactions with CD44 vary based on cell type. These interactions have been shown to play a role in cell functions such as cell adhesion, metastasis, endocytosis, cell signaling, cytokine release, and matrix deposition [206,216]. Signaling pathways triggered by CD44 binding include tyrosine kinases (p185 and c-Src), Rholike GTPases, and Rac1 signaling [217]. CD44 recognizes HA via various interactions such as hydrophobic interactions and numerous hydrogen bonding sites [218].

Receptor for HA-mediated mobility (RHAMM) is another major receptor for HA binding. HA interacts with the B(X7)B motif found in RHAMM, where “B” is a basic amino acid, excluding histidine, and “X” includes at least one basic amino acid and excludes acidic residues [219]. HA RHAMMs are found on the surface of cells, in the cytosol, and in the nucleus and activate a number of signaling cascades [217]. Finally, HA interacts with the hyaluronan receptor for endocytosis (HARE), which aids in clearing 80–90% of total HA [199,206].

The interaction between cells and HA has also been shown to depend on the molecular weight of HA [198,217]. In particular, studies have shown that low MW HA fragments can lead to the expression of inflammatory genes in a variety of cell types [198,203]. High MW HA fragments have been shown to activate protein-tyrosine kinase pathways in ECs and Ras-transformed fibroblasts [217]. One potential way for cells to discern various chain lengths of HA is that CD44 receptors can cluster and crosslink together to bind to numerous binding sites along a single HA molecule [203,216]. When smaller HA fragments (oligosaccharides of ~6–18 sugars) competitively displace larger HA-CD44 complexes, it signals an unstable complex and the cellular response may come to a halt [203,220]. An alternative rationale for the differences in the effect of different molecular weights is that size may impact the uptake of HA, and therefore intracellular signaling is an important factor [203].

HA is degraded into different MW fragments by the mechanisms detailed in Section 2.1.2.4. The degradation of HA is a necessary step to signal that homeostasis has been perturbed [198,217]. When HA is cleaved into smaller fragments (HA <1 MDa or HA oligosaccharides), these fragments can lead to scar tissue formation or induce an immune response [198,199,221]. HA is largely cleared from circulation via endocytosis in the lymph nodes and liver by HARE receptors [199]. Finally, another method for altering the cell signaling dynamics is for chondroitin sulfate (CS) to be replaced by HA via trans-esterification or non-covalent bonds to heavy chains [222]. When the exchange of CS for HA occurs, HA can covalently bind to the surface of cells and participate in the formation of additional pericellular matrix [222,223].

2.3. Summary and future outlook of collagen and HA function

Collagen and HA are biomolecules found in the ECM and provide mechanical stability and biochemical and biomechanical cues to cells. Collagen is the most abundant protein in the human body and forms crosslinked fibrous networks in the ECM. HA is a negatively-charged, non-sulfated GAG and provides crucial signals for biological processes, including wound repair and inflammation. Both collagen and HA interact with surface receptors of cells to induce cell activities such as migration, proliferation, and matrix remodeling. Thus, collagen and HA confer desirable properties for biomedical applications including regeneration of cartilage, bone, and skin. Currently, most research focuses on collagen I and HA scaffolds, which offer platforms to decouple and study complex biological processes. In the future, creating blends consisting of numerous collagen types may create more efficacious medical treatments as more than one type of collagen is often present within native tissue. Furthermore, these scaffolds can help uncover the biological effects of HA molecular weight and CD44 interactions with HA since these factors are not yet fully characterized for various tissues.

3. Sources and commercial applications of collagen and HA polymers

Collagen can be naturally sourced or synthetically developed. Shorter sequences of collagen, including collagen mimetic peptides [224–227], collagen-like proteins found in bacteria [228–232], and hydrolyzed collagen peptides [233] have also been developed into biomaterials; however, this section will focus on full-length collagen from animal sources and recombinantly-produced collagen developed in various host organisms due to their ubiquitous use in the biomedical field. HA is commercially sourced from animals and microorganisms. This section will focus on these commercial sources as well as the use of recombinant microorganisms and cell-free methods to produce HA. Finally, the commercial applications of collagen and HA polymers will be discussed.

3.1. Sources and characteristics of different types of collagen

3.1.1. Animal-derived collagen

As the most abundant mammalian protein [6], collagens, specifically collagen I, can be sourced from the majority of animals. Mammalian collagens are of interest due to the high level of conservation in the triple helical region across species [234–236] and the presence of post-translational modification machinery that confers the biochemical functions of collagen [237,238]. The major sources of collagen for scientific research are highly collagenous tissues, such as skin, tendons, bones, and cartilage, derived from cows, pigs, and sheep [239]. The food industry provides a bountiful supply of tissues for collagen extraction without extra cost, and value is added to previously polluting byproducts. This practice has resulted in high yields of low-cost collagen that is similar to human collagens and ideal for biomedical research. Collagens from equine, murine, and avian sources are also common and have been characterized and studied for biomedical applications [239]. More exotic sources, which include kangaroo tail tendon [240], alligator bone [241], and frog skin [242], highlight the abundance of the protein.

Collagen extraction protocols consist of four general steps: 1) raw material separation and size reduction, 2) removal of non-collagenous components, 3) acid or enzymatic collagen extraction, and 4) purification by salt precipitation or chromatography methods [29,243,244]. Crosslinked collagen derived from animals is not water soluble; thus its extraction protocols involve chemical and enzymatic reactions to increase the solubility of the protein. Organic acids, most commonly acetic acid, are used to break the non-covalent inter- and intramolecular bonds and increase the solubility of the protein [29] to yield acid-soluble collagen. Acid solubilization can be followed by enzymatic extraction, which improves the yield of the protein [245]. Pepsin-soluble collagen is formed by using a non-specific collagen enzyme, typically pepsin, to increase solubility by cleaving the telopeptide regions on the ends of the triple helical structures, which are major sites of interchain cross-links [29]. The method of extraction results in distinct polymerization profiles (Fig. 3), subtle architectural differences in fibril network organization and fibril–fibril interactions, and differences in mechanical integrity [243,245].

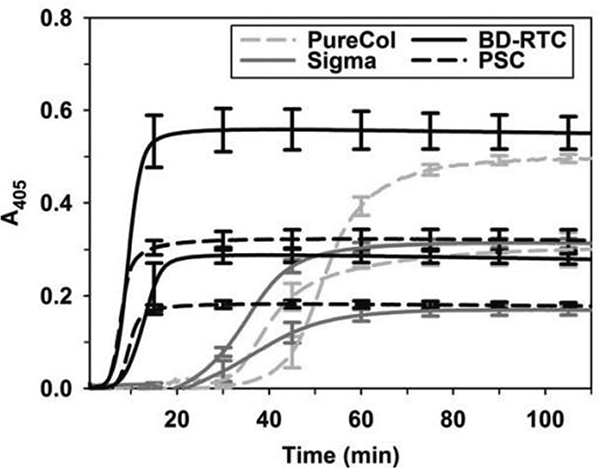

Fig. 3.

Collagen origin and processing affects polymerization kinetics. Polymerization kinetics of “in house” extracted porcine skin collagen (PSC) extracted using acid compared to commercially sourced acid solubilized bovine dermis (Sigma), acid solubilized rat tail (BD-RTC) and pepsin treated bovine dermis (PureCol) collagens. Collagen was polymerized at concentrations of 0.5 and 1.0 mg.ml (lower and upper curve for each collagen source, respectively) and measured spectrophotometrically at 405 nm. Reproduced with permission from Kreger et al., 2010 [245]. Copyright 2010 Wiley Periodicals, Inc.

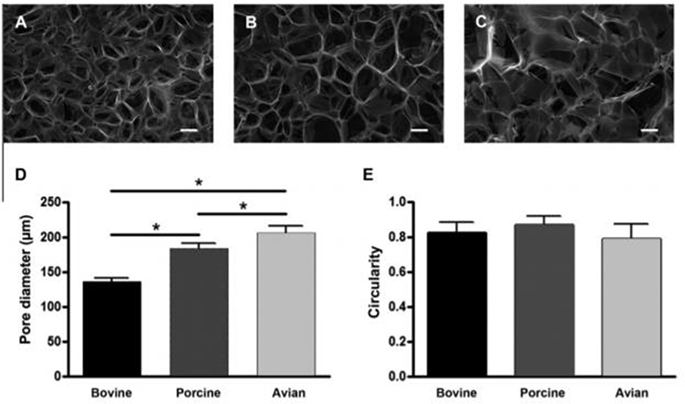

Despite animal-derived collagen leading to an abundance of low-cost material, variabilities due to animal species and choice of tissue contribute to variations in material properties. Recently, there has been increased interest in characterizing collagen material properties from different animal species [112,246–249]. Differences in material properties, including ultimate stress, ultimate strain, and toughness, have been observed [246]. Microstructural architecture also appears to vary with origin species [247,248], and there are pore size variations as large as 51.6% in chitosan-collagen crosslinked gels based on species (Fig. 4) [247]. Collagen from tissues with strict hierarchical organizations, such as equine tendons, results in materials that retain partial lateral packing and have higher mechanical properties [112] compared to other sources. In addition, compared to collagen from young mice, collagen originating from older mice formed fibrils more slowly, generated fibrils with smaller diameters, and resulted in networks that were less dense [250]. Despite these material variabilities, collagen from young or old mice resulted in scaffolds that promoted cell adhesion; however, ECM deposition amount, and gel contraction varied [250]. Comparison studies of collagen from different species often fail to consider the age of the animal, extraction methods, and tissue of choice, and thus conclusive generalizations are difficult to make.

Fig. 4.

Animal source of collagen impacts the microstructure of polymerized scaffolds. Scanning electron microscopy images of collagen–chitosan scaffolds made with (A) bovine, (B) porcine, or (C) avian collagen (scale bar represents 100 μm). (D) Average pore size of scaffolds from bovine, porcine or avian sources. Give the same fabrication process, collagen source results in significant differences in pore size. (E) No significant differences were observed in the circularity of pores. Reprinted from Acta Biomaterialia, 7, R. Parenteau-Bareil, R. Gauvin, S. Cliche, C. Gariépy, L. Germain, F. Berthod, Comparative study of bovine, porcine and avian collagens for the production of a tissue engineered dermis, 3757–3765, Copyright 2011, with permission from Elsevier [247].

Concerns about safety of materials sourced from animals prevent full clinical translation. The incidence of adverse reactions to acellular collagen implants are rare, but they do occur [251]. Animal sources, especially bovine, carry inherent risk of disease transmission, including bovine spongiform encephalopathy. Bovine collagen is used widely, but diseases originating from bovine collagen can be dormant for decades before the appearance of the first symptoms [247]. Clinical observations indicate that between 2–4% of the population possess an allergy to bovine collagen I [252–255]. An additional 1% develop an allergy to bovine collagen postoperatively [251]. Granuloma and localized inflammation have been observed in rare cases and resolved within a year [251].

Although the triple helical regions are mainly conserved across species, the amino acid sequences of the terminal regions exhibit ≤50% variation between species [256]. Speculation that this region is a source of adverse immune reaction led to the fabrication of atelocollagen, which is collagen treated with pepsin to remove the N- and C- terminal telopeptides. The lack of telopeptides, however, alters nucleation and fiber structure [257,258]. Collagen I is not typically associated with an autoimmune response. However, studies implicated collagen II as a potential auto-immunogen [251,259–261]. For a detailed review of collagen immunogenicity, see the 2004 review by Lynn et al. [251].

Religious and cultural beliefs further prevent clinical translation of bovine and porcine collagens. In addition, pepsin, an enzyme crucial for the extraction of collagen from animal sources and the production of atelocollagen, is typically of porcine origin and raises further cultural concerns [29]. The safety and religious concerns about bovine and porcine collagens have paved the way for marine-sourced collagen as an alternative.

Marine animals are typically associated with less religious and cultural significance and can be readily sourced from the food industry. Marine sponges and jellyfish [29,262] are the most widely studied marine invertebrates for collagen source as they are cultivated for their pharmacologically active terpenoid and alkaloid compounds [29,263]. Other invertebrates that have been studied include cuttlefish, sea anemone, prawn, starfish, jellyfish, sponge, sea urchin, octopus, squid, and mollusk [29]. Collagen derived from aquatic species only slightly differs in amino acid composition from mammalian sources [29]. However, some sources lack imino acids compared to human collagen. These molecules are crucial for the structural integrity of collagen fibers; thus, their absence leads to denaturation temperatures as low as 16–20 °C [29]. The low denaturation temperature is a concern as clinical translation will require the material to remain intact at human physiological conditions. Collagen extracted from carps, tilapia, and few other warm water fish have denaturation temperatures between 32–37 °C and thus are better suited for biomedical applications [29]. Finally, marine collagens are preferable to bovine collagens from a cultural perspective. For a detailed review of marine collagens, see these review papers [29,33].

Despite source variability, cultural and religious concerns, and safety issues, animal-derived collagen remains the gold standard material for tissue engineering applications. Animal-derived collagen is abundant in nature, can be extracted from food and pharmaceutical byproducts, and resembles human collagen in biomechanical and biochemical aspects. Thus, animal-derived collagen is widely available and accessible for research and clinical purposes.

3.1.2. Recombinant human collagen

Given the drawbacks of animal-derived sources of collagen, recombinant human collagen offers an alternative means for developing biocompatible collagen with low variability and immunogenicity. Proteins are recombinantly produced by cloning genetic material into a host that produces the protein. Recombinant collagen is particularly attractive for the production of collagen types other than collagen I because sourcing and purification of less common collagen types are difficult.

Researchers have developed recombinant human collagen, but its production needs to achieve: 1) scalable and inexpensive production that can compete with animal-derived sources, 2) human collagen levels of post-translational modifications and higher order structural arrangement, and 3) heterotrimeric collagen expression in addition to homotrimeric expression [264]. Different host organisms have been developed to address these challenges (Table 4).

Table 4.

Advantages and disadvantages of different hosts in recombinant human collagen expression and production.

| Host | Advantages | Disadvantages | Collagen Types |

|---|---|---|---|

|

Bacteria • Escherichia coli [265,266] |

• Inexpensive • Scalable • Well-characterized |

• Poor transformation efficiency of long plasmids • No native enzyme for post-translational modification |

III [265,266] |

|

Yeast • Saccharomyces cerevisiae [267–270] • Pichia pastoris [271–274] |

• Low maintenance cost • Well-characterized |

• No native enzyme for post-translational modification | I [267,270,271] II [272] III [268,269,273,274] |

|

Plants • Tobacco [275–277] • Maize [278] |

• Good transformation efficiency of long plasmids • Native prolyl hydroxylase activity • Scalable |

• Low native enzyme hydroxylation activity | I [275–278] |

|

Mammalian cells • Chinese hamster ovary cells [279] • HeLa cells [280] • human embryonic kidney 293 cells [281–283] • Fibrosarcoma HT 1080 cells [283–285] |

• Simple cloning schemes • High cloning efficiency • Native hydroxylase and lysine glycosylase activity |

• Poor yield • Costly to culture • Long production times |

I [284] II [285] IV [279] V [281] VII [282] X [283] XII [280] |

|

Insects • Spodoptera frugiperda Sf9 cells [286–290] • Drosophila melanogaster S2 fly cells [291] • Bombyx mori silkworms [290,292,293] and silkworm cells [290] |

• Established transfection protocols • High density culture for scale-up • Cheaper scale-up than mammalian cells • Native hydroxylase activity |

• Low native enzyme hydroxylation activity | I [286,292] II [290] III [287,288,293] IX [289] XXI [291] |

Yeast and bacterial recombinant hosts are well characterized and inexpensive; however enzymes required for post-translational hydroxylation and glycosylation must be transformed into these hosts [266,294]. More complex systems, such as plant, mammal, and insect cell hosts, have native enzymes for post-translational modification, but yield and enzyme activity are low. Often, recombinant collagen constructs result in truncated polypeptide chains due to native host protease degradation or codon usage bias [295]. Overall, yield and native post-translational modifications continue to elude the recombinant collagen community to achieve true mimetics of human collagen, but several groups have used recombinant human collagen to develop novel biomaterials [296–300].

3.2. HA sources and property variation

3.2.1. Commercial extraction methods of HA production

The bioactivity of HA and its possible applications are highly dependent on the polymer molecular weight [155,301]. It is difficult to obtain high MW HA due to degradation of HA during extraction, purification, storage, and sterilization [302,303]. HA is sensitive to harsh processing conditions such as extreme pH, high temperatures, and long durations of heating [304]. Extreme acidic conditions disrupt hydrogen bonding and can lead to random polymer degradation and a reduction of viscosity. If thiols or transition metals are present, they can cause the production of reactive hydroxyl radicals that cleave HA [160]. If HA is produced with residual hyaluronidase, it is susceptible to enzymatic degradation [305]. These chemical, thermal, and enzymatic factors can result in lower MW HA products with wide polydispersity.

HA, unlike collagen, is structurally preserved across species [306]. Therefore, HA extracted from other species is chemically identical to human HA. It was initially extracted from sources, such as rooster combs (7.5 mg HA per g of tissue) and human umbilical cords (4.1 mg/g), that have high HA concentrations [302,307,308]. High MW HA (~1 MDa) can be derived from tissues [155] and is useful in ophthalmological, orthopedic, and tissue engineering applications [301,309,310]. However, the yield of animal-sourced HA is limited by the naturally occurring concentrations in tissues, and adverse immune reactions can occur from any proteins, proteoglycans, or DNA remaining from the extraction and purification processes. These limitations have decreased the use of animal-sourced HA.

3.2.2. Production of HA based on microorganisms

HA was commercially produced from several microorganisms after HA synthase (HAS) operons were identified in Streptococcus bacteria in the 1990s [311,312]. HAS enzymes from Streptococcus species extend the HA chain from the reducing end and are membrane-bound, which is similar to human HAS enzymes [307]. The ideal host organism should be able to efficiently synthesize high MW HA, be non-pathogenic, and have no hyaluronidase activity [302].

Initial commercial production was performed with Streptococcus equi and Streptococcus zooepidemicus, and it was found that S. equi natively produce HA with a lower MW than S. zooepidemicus [160]. Groups have been investigating more efficient strains and production/purification systems for these Streptococcus strains [313–320]. For example, wild-type production of HA from S. zooepidemicus produced HA MWs of ≤1.8 MDa, whereas engineered strains produced MWs ≤3.4 MDa [321].

Numerous non-pathogenic microorganisms, including Bacillus subtilis [322,323], Lactococcus lactis [324,325], E. coli [326–328], and others [329–333], have been genetically manipulated to produce HA at a research scale [307,334]. B. subtilis is a commonly used industrial producer and is generally recognized as safe (GRAS). It has native enzymes homologous to several HAS enzymes in Streptococcus, and other necessary HAS genes can be introduced through transformation [322,323,325,335,336]. L. lactis has also been used for its GRAS status and lack of hyaluronidases [324,337,338]. Many microorganisms, such as E. coli, lack native HAS genes, so genes from HA-producing bacteria must be transformed into the hosts [326–328].

There are several limitations inhibiting the progress of microorganism production of HA. Large scale fermentation of HA is difficult due to increased viscosity as HA concentration increases. High viscosity prevents proper mixing and results in a poor oxygen transfer rate, which reduces yield [339]. Researchers characterized in vitro and in vivo HA synthesis from different bacterial strains and determined that the maximal HA MW is specific to an individual synthase, but shorter HA chains may result due to physiological and metabolic factors and production conditions [321,340,341]. Polydispersity in the MW of the final product is still an issue as the distribution is heavily controlled by reaction stoichiometry and other culture conditions. Finally, there is the possibility of endotoxins from pathogenic microorganisms or bacterial contamination from binding proteins and nucleic acids that may elicit a human immune response [334]. Compared to HA extraction from animals, bacterial production commonly results in shorter HA chain length but higher yield.

3.2.3. Cell-free methods of HA production

To avoid several of these drawbacks of microorganism fermentation, HA has also been produced at the research-scale in cell-free in vitro systems that utilize purified HAS enzymes. Although most species produce HAS enzymes that need to be tightly bound to the cell membrane, Pasteurella multocida produces HAS enzymes that do not require membrane association and can synthesize HA in a cell-free system [342–344]. Researchers are also making progress to develop the more ubiquitous membrane-bound HAS enzymes for cell-free production [345].

Though non-pathogenic hosts and cell-free systems offer alternatives to current commercial production, these systems do not have the capacity to produce HA at a commercial scale. All current commercial and experimental methods are limited in their ability to efficiently produce high MW HA with a narrow molecular weight distribution at a large scale. The increase in use of HA in the biomedical industry will continue to drive future innovation to optimize HA production.

3.3. Commercial applications of collagen and HA polymers

Due to their biological activity and relative abundance, both collagen and HA polymers have been used in a variety of biomedical commercial applications. To meet the requirements of their intended biomedical uses, the polymers are often modified and processed to create various forms. Additional factors, including other biopolymers and growth factors, are added to work in conjunction with collagen or HA for the intended biomedical use. While both collagen and HA have been used extensively, few products incorporate both in combination. As such, this section will detail several commercial applications of collagen and HA, including orthopedic, ophthalmic, and surgical applications.

3.3.1. Collagen matrices and sponges

Collagen matrices are widely used for clinical applications ranging from skin grafts and wound dressings, to regenerative orthopedic applications. Though the specifics may differ between manufacturers, the general procedure for creating collagen matrices involves dissolving previously-extracted collagen at high concentrations, then freezing and lyophilizing the material before commercial distribution. Further processing of this matrix through extensive chemical crosslinking results in a collagen sponge, which is able to absorb large quantities of water [346]. Most commercial collagen products are primarily composed of collagen I due to its greater availability compared to other collagen types.

3.3.1.1. Collagen matrices for wound dressings and skin healing

Collagen matrices have been produced by several companies as platforms for treating burns and chronic skin wounds. By retaining water and facilitating cell migration and proliferation, collagen matrices maintain a moist environment at the wound site and promote wound healing. Manufacturers often add other components to collagen sponges to augment bioactivity and effectiveness. Examples include Integra Dermal Regeneration Template Single Layer (Integra LifeSciences, USA), which is a collagen sponge with GAGs [347,348], and Matriderm (MedSkin Solutions Dr. Suwelack AG, Billerbeck, Germany), which is a collagen matrix with elastin [347,349,350]. Although these products are sold as acellular scaffolds, some manufacturers sell collagen-based skin graft products, such as Apligraf (Organogenesis, USA), that are pre-cultured with dermal fibroblasts several weeks prior to cryopreservation and packaging [351–353].

3.3.1.2. Collagen matrices for orthopedic applications

To treat critical-sized bone defects, collagen sponges have been used to provide a scaffold for the growth of new bone. The INFUSE bone graft (Medtronic, USA) is a collagen sponge loaded with recombinant human bone morphogenetic protein 2 (rhBMP-2) [354]. This collagen sponge delivery vehicle has been used in several orthopedic applications including the filling of craniofacial bone defects and spinal fusions to treat degenerative discs [355]. Collagen-based fillers or scaffolds such as Collagraft (Zimmer Biomet, USA), Collapat (Zimmer Biomet, USA), Healos (DePuy Synthes, USA), Infuse (Medtronic, USA), etc. have US Food and Drug Administration (FDA) approval for use in orthopedic treatments [356,357].

For the treatment of critical-sized cartilage defects, collagen matrices have been used as a delivery vehicle for matrix-assisted autologous chondrocyte implantation (MACI) procedures. Despite cartilage consisting primarily of collagen II, most collagen matrices for MACI procedures are made of collagen I. Some matrices, such as Chondro-gide (Geistlich Pharma, Germany), Maix (Matricel, Germany), and MACI (Verigen, Germany), are a blend of collagen I and III [358,359]. These collagen matrices are often made into thin sheets and secured into place using an adhesive such as fibrin glue.

3.3.2. Collagen sutures

Resorbable sutures are absorbed over time and eliminate the need for removal by a clinician after wound healing. Catgut sutures are made by twisting strands of animal-derived collagen together [360], and a patient’s own proteolytic enzymes are capable of degrading the suture over time. This process is much faster than the degradation of synthetic polymers, such as poly(lactic-co-glycolic acid), that hydrolyze slowly and hold tensile strength for much longer [360,361]

3.3.3. Recombinant collagen biomaterials

Commercial recombinant human collagens are regularly used in biomedical research. Fibrogen commercially developed recombinant human collagen from yeast [232]. A group of researchers used this collagen to develop a matrix for the treatment of myocardial infarction [362]. Another group used Fibrogen recombinant collagen II for the chondrogenesis of mesenchymal stem cells (MSCs) [363]. Fujifilm developed a commercial recombinant collagen peptide based on collagen I. This material has been used to improve culture conditions for stem cells [364–367], to mitigate slowing of cardiac conduction by stromal cells [368], and to serve as a bone graft material [369].

3.3.4. HA solutions

One common treatment for osteoarthritis is the supplementation of the patient’s synovial fluid with the injection of high MW HA. To further increase the viscosity of the hyaluronic acid, the polymer may be mildly crosslinked, such as in Synvisc (Sanofi, France) [370]. However, many commercial products are sold as unmodified hyaluronic acid or sodium hyaluronate. Despite its wide-spread use, the efficacy of synovial fluid viscosupplementation is still disputed [371].

Because HA is a natural component of the vitreous humor, solutions of HA have also been manufactured for ophthalmic applications. HA solutions have been used to aid in the implantation process of intraocular lenses following cataract surgeries [372]. However, because of its high hydrophilicity, HA has been found to adversely increase intraocular pressure following procedures, and work is being done to mitigate this side effect [373].

For soft tissue reconstruction or plastic surgery purposes, HA solutions can be injected subcutaneously as a dermal filler. To prolong its lifetime after injection, the polymer chains can be modified to prevent enzymatic degradation by hyaluronidase. An example of a modified product is HYADD3 (Fidia Advanced Biopolymers, Italy), where a dodecylamine is conjugated to the carboxyl group for steric hindrance, which slows down enzymatic degradation [374].

3.3.5. HA for wound healing

To create HA-based skin grafts and wound dressings, many manufacturers have modified the polymer, such as through benzyl esterification, to reduce its solubility in water [375]. The degree of modification can be modulated to control the degradation properties of the material. Commercially, benzyl-esterified HA is sold under the name HYAFF, with different grades depending on the degree of modification [375]. This material can then be processed into bulk products. For example, HYALOFILL (Anika Therapeutics, USA) is a soft fabric-like material made from uncrosslinked HYAFF fibers and is used for wound dressings [376]. Composite material wound dressings have also been developed using HYAFF, such as the Hyalomatrix wound dressing (Fidia Advanced Biopolymers, Italy), which combines uncrosslinked HYAFF fibers with a silicone membrane for added stiffness [377].

3.3.6. Regulation of commercial products

Currently, the FDA treats many of these collagen- and HA-based products as medical devices. General FDA guidance conforms to the ISO standard 10933–1:2018: Biological Evaluation of Medical Devices, which outlines the various biocompatibility tests for evaluation of medical devices [378]. Tests include an examination of cytotoxicity, material-mediated pyrogenicity, acute and chronic system toxicity, carcinogenicity, and the effects of implantation. Other standards, such as ASTM F2212–20: Standard Guide for Characterization of Type I Collagen as Starting Material for Surgical Implants and Substrates for Tissue Engineered Medical Products (TEMPs) (ASTM International, F2212–20) [379] and ASTM 2150: Guide for Characterization and Testing of Biomaterial Scaffolds Used in Tissue-Engineered Medical Products (ASTM International, ASTM F2150 – 19)[380], provide guidance on how to test the biocompatibility of these materials. In general, collagen- and HA-based materials meet these guidelines due to their natural bioactivity and degradability [381]. However, care must be taken with regard to the processing of the materials to ensure they do not contain toxic contaminants, are sterile after processing, and that modifications do not elicit adverse effects upon application. For new products, premarket approval is required by the FDA to ensure that the product is safe to use and operates as intended, based on both laboratory and clinical data. However, in cases where it can be proven that the product is similar to one already on the market, the FDA approval process can be expedited through the premarket notification path, also known as a 510(k). This approval pathway allows for products similar to those whose safety and efficacy have already been proven to reach the market significantly faster.

4. Fabrication of collagen and HA hydrogels

Crosslinking, chemical modifications, and environmental conditions such as pH and temperature can be used to tune the properties and functionalities of collagen and HA hydrogels. These hydrogels are usually designed by modulating various physical and chemical parameters to achieve the desired properties suitable for specific applications, which are discussed in detail in Section 6. Discussed below are some of the specific factors and modifications that can be used to tune the properties of collagen, HA and ColHA hydrogels.

4.1. Fabrication parameters and polymerization conditions for collagen hydrogels

Collagen fibrillogenesis and polymerization into a hydrogel depend on different parameters such as the collagen source, concentration, pH, temperature, and ionic strength. These factors regulate the hydrogen bonding, hydrophobic interactions, and electrostatic interactions between amino acid residues and control polymerization rate as described below [382,383].

4.1.1. Collagen source and solubilization method

Animal source (e.g., species, age), tissue source (e.g., skin, tendon), and extraction methods (e.g., acid-solubilized, pepsin-digested) play important roles in collagen polymerization kinetics and hydrogel properties. Kreger et al. reported that, under identical polymerization conditions, acid-solubilized porcine skin collagens polymerize more quickly due to intact telopeptide regions as compared to pepsin-digested bovine or porcine collagens [245]. Wolf et al. found that gels of pepsin-digested collagens have longer fibrils and larger pores compared to acid-solubilized collagen gels, which have high fibril density, shorter fibrils, and smaller pores [243]. The age of the animal used for collagen extraction also plays a vital role in polymerization. Collagen from older animals resulted in more malleable hydrogels with smaller-diameter fibrils and a lower density of fibrils [250].

4.1.2. Collagen concentration

Increasing the collagen concentration in hydrogels reduces the diffusion coefficient of molecules diffusing within the hydrogels [384]. Ramanujan et al. demonstrated this inverse relationship by using fluorescence recovery after photobleaching to measure diffusion coefficients of dextrans with various molecular weights (4–2000 kDa) in collagen hydrogels. Similar results were reported with decorin- or HA-supplemented collagen hydrogels containing 2000 kDa dextran [385] and collagen-alginate hydrogels with 3–500 kDa dextran [386].

Collagen concentration also affects hydrogel properties. For example, an increase in concentration resulted in hydrogels with higher fibril density and reduced pore size [387,388]; however, fibril diameters were unaffected by changing collagen concentration only [245]. Several investigators have also reported a positive correlation between collagen concentration and the shear and elastic moduli of the hydrogel [245,389,390]. Fraley et al. however, documented that, the elastic modulus decreased when collagen concentration increased from 1 to 1.5 mg/mL and then increased when the concentration increased from 1.5 to 2.5 mg/mL [391]. Increasing the collagen concentration from 1 to 1.5 mg/mL also decreased the alignment of collagen fibers without affecting the average pore size, whereas increasing from 1.5 to 2 mg/mL drastically reduced the pore size and slightly decreased the fiber alignment.

4.1.3. pH

pH has a significant influence on the resulting physical and mechanical properties of collagen hydrogels and depends on various factors such as the ratio of collagen to neutralization agent, collagen dilution ratio, type of buffer, and collagen concentration [392]. An increase in pH results in collagen networks with longer and thinner fibers and increased pore density with reduced pore area fraction and size [393,394]. Furthermore, the rigidity of collagen gels increases with an increase in pH [395].

4.1.4. Temperature

At higher temperatures, the self-assembly of collagen molecules occurs more rapidly due to a larger number of hydrophobic and electrostatic interactions that increase fibril precipitation while limiting lateral aggregation and result in fibers with a reduced number of bundled fibrils [396,397]. Higher polymerization temperature, therefore, results in a less-ordered structure with altered mechanical and transport properties. Yang et al. varied the polymerization temperature from 4 °C to 37 °C and observed that lower polymerization temperatures resulted in enhanced bundling of fibrils that resulted in increased fiber diameters, larger pore sizes, and, consequently, better proliferation and migration of glioma cells [396,397]. Chrobak et al. emphasized the role of temperature on gel stability by creating more stable and less degradable microchannels in gels polymerized at room temperature compared to gels formed at 37 °C [398].

4.1.5. Ionic strength

The structural and mechanical properties of collagen hydrogels are highly influenced by the ionic strength of the polymerization solution. Gobeaux et al. demonstrated this effect by polymerizing gels at ionic strengths ranging from 24 to 1300 mM and reported variations in hydrogel structural and optical properties [387]. Even with a smaller range (64.2 to 174 mM), Achilli and Mantovani found that variations in ionic strength impacted the mechanical properties of gels [399]. They also showed that the dependence of the compression modulus on ionic strength is interdependent on pH and temperature. Wood and Keech noted that collagen fibril diameter generally increased at higher ionic strengths, and that, at lower ionic strengths, collagen self-assembly was faster and resulted in a smaller number of bundled fibers [400].

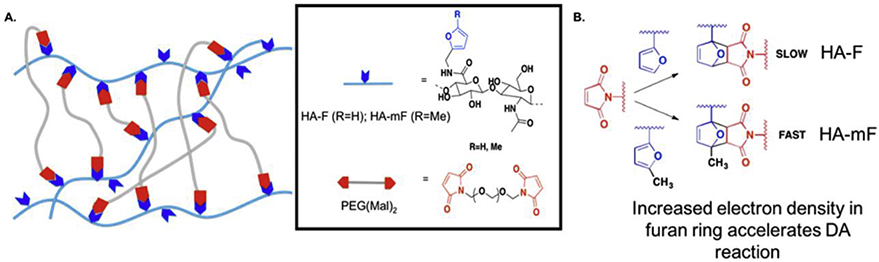

4.1.6. Macromolecular crowding agents