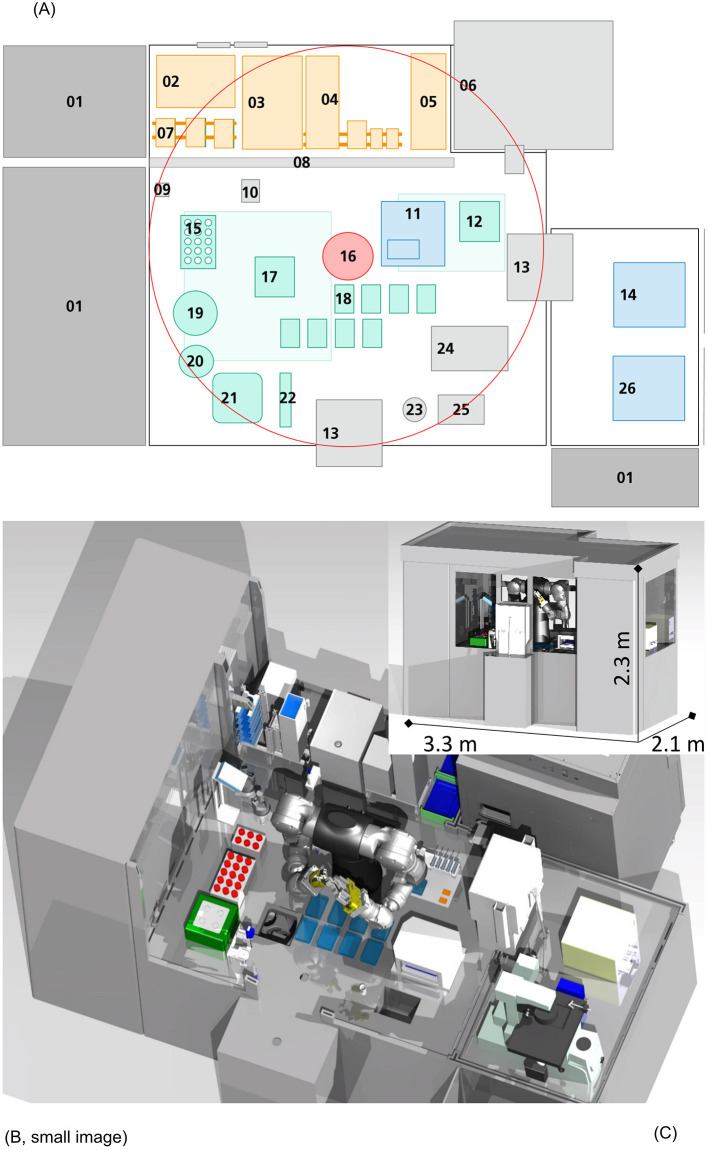

Figure 2.

Automation scheme and visual representation. In this figure, a 2D (A) and 3D [(B): frontal view, (C): sliced view] representation of this concept is shown. The platform is equipped with devices for each handling step: 01 Ventilation system, 02 Freezer (−20°C), 03 Fridge (4°C), 04 Disposables storage, 05 Packaging material, 06 Incubator (37°C), 07 Storage for plates and membranes, 08 Gate, 09 Barcode reader, 10 Washing station, 11 Sampling station, 12 Shaker, 13 Air-lock, 14 Cell counting device, 15 Storage for Cell culture tubes (temperature controlled), 16 Six axis dual arm robot, 17 Centrifuge, 18 Plate handling positions, 19 Decapper (centrifuge flask), 20 Decapper (Cell culture tubes), 21 Tissue grinder, 22 Pipettes, 23 Liquid waste, 24 Sealing machine, 25 Solid waste, 26 Microscope. The central six axis dual arm robot (16) can reach the circumference shown in (A). Necessary equipment, disposables and liquids are safely channeled in through an air lock linked glove box (orange), without the need of personnel entering the isolator directly from an unclassified maintenance back side. Pre-packed, sanitized disposables, materials or biologicals can be unpacked easily and set in place for robot-driven procession. Devices for cell culture (green) and quality control (blue) are included in the design. The platform is scaled to the parallel production of five N-TECs at a time, with the possibility of increasing manufacturing capacity further e.g., by implementation of larger storage devices.