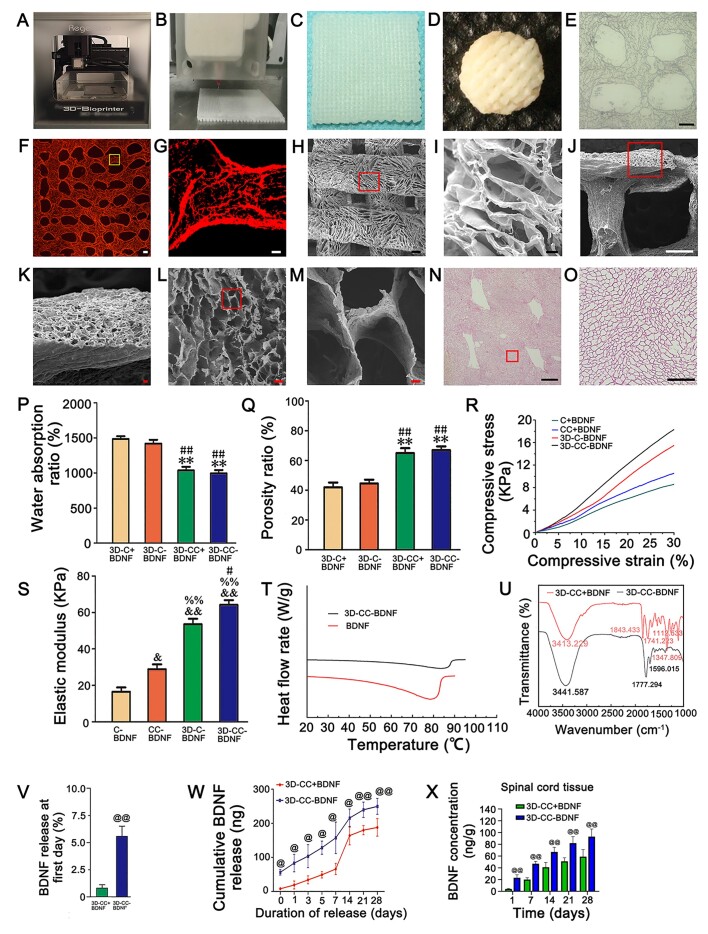

Figure 1.

The properties of scaffolds. (A) 3D printer for scaffold preparation. (B, C) 3D-CC-BDNF fabricated by a 3D printer. (D) 3D-CC-BDNF was freeze dried by a freeze dryer. (E–J) The images of light microscopy (E), fluorescent microscope (F–G), SEM (H–M) and HE staining (N–O) revealed were porous microstructure of 3D-CC-BDNF. G was an amplified image of the yellow box in F. (I, K, M, O) were an amplified image of the red box in (H, J, L, N), respectively. (P–S) The water absorption (P), the porosity (Q), the compressive strain–compressive stress curve (R), and the elastic modulus (S) of the scaffolds. (T) Differential scanning calorimetry curve of BDNF and 3D-CC-BDNF during heating. (U) Infrared spectra of 3D-CC-BDNF and 3D-CC+BDNF. (V) Percentage of BDNF released from 3D-CC-BDNF and 3D-CC+BDNF at first day. (W) Total amount of cumulative release of BDNF within 28 days. (X) BDNF concentration-time curve for spinal cord tissue after injection. Data were presented as mean ± SD; n = 3. **P < 0.01 vs 3D-C+BDNF. #P < 0.05, ##P < 0.01 vs 3D-C-BDNF. &P < 0.05, &&P < 0.01 vs C-BDNF. %%P < 0.01 vs CC-BDNF. @P < 0.05, @@P < 0.01 vs 3D-CC+BDNF. Scale bars = 300 µm in panels (E, F, H, J, N), 50 µm in panels (G, I, K, L, O), 5 µm in panel M. n = number of animals under each condition (n is expressed as dots in the bars) in X, n = 10.