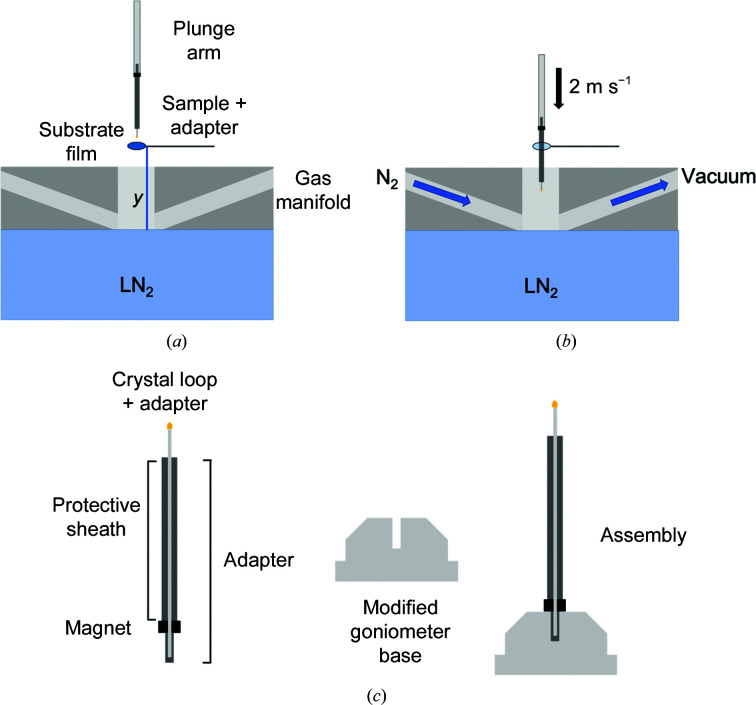

Figure 1.

(a) Plunge-cooler design for MMQX, including a substrate-containing film. A polymer-film crystal mount on a stainless-steel pin in a magnetic holder is placed on a plunge arm attached to a high-speed linear-translation stage. To remove cold N2 gas that forms above the LN2 and ensure that the reaction proceeds at room temperature to the LN2 surface, a gas-management manifold flows warm N2 gas across the LN2 surface within its plunge bore, and removes cold and warm gas using vacuum. The time point t is determined by the height (y) of the film above LN2 and the plunge speed. (b) A crystal is plunged through the substrate film at a speed of 2 m s−1, then through room-temperature N2 gas present in the bore of the gas-management manifold to the LN2 surface and then through the LN2. (c) Pin adapter for plunge-cooling and MMQX experiments. To reduce the needed aperture size of the substrate-containing loop, the crystal is plunged in the pin holder. Once cooled, the pin holder is inserted into a modified ALS-format goniometer base. An optional protective sheath for pre-mixing incubations is shown.