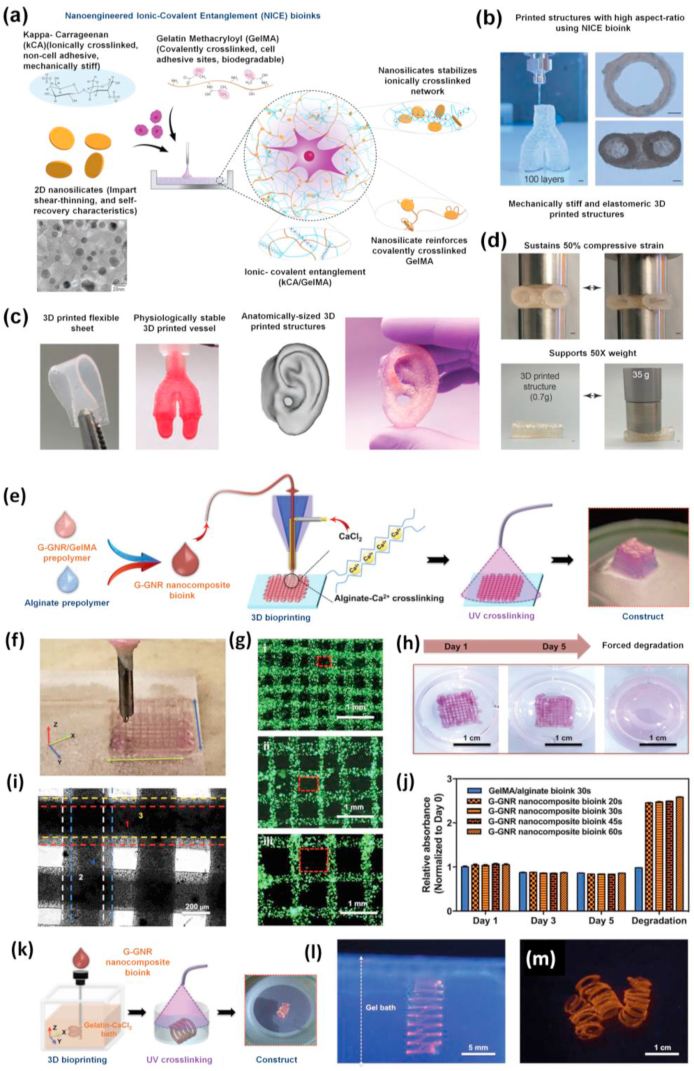

Fig. 16.

Tough, elastic, and highly printable NICE bio-ink formed by bond reinforcement mechanisms (a) Dual reinforced polymeric network formed from GelMA and kCA through ionic–covalent entanglement via nSi. (b) Self-supported hydrogel constructs printed using NICE bio-ink exhibit a high aspect ratio and print fidelity. (c) Various bioprinted constructs resulted from NICE bio-ink which closely resembles anatomical structures (d) The bioprinted structures exhibit superior rigidity and elastic properties and could support more than 50-times of their actual weight. Reproduced with permission from Ref. [190] copyright © 2018 American Chemical Society. (e) Illustration showing the bioprinting process using GNR/GelMA bio-ink. (f) Printing is illustrated on a cartesian co-ordinate system and its view through a microscope showing a stacked arrangement of different layers. (g) 3D printing of constructs with diverse internal grids. GNR/GelMA contained green beads displays printed fibers. (h) Bioprinted constructs show stability in culture medium up to 5 days and also show its forced degradation in an enzymatic environment (i) The absorbance studies of cell culture medium revealed the GNR release upon degradation (j) Illustrating bioprinting using the 3D embedded nanocomposite bio-ink. (k) Shows the spiral construct in the support bath composed of gelatin and CaCl2 after printing. (l) Bioprinted constructs were collected from the supporting bath without damaging it and incubated in the culture medium. Reproduced with permission from Ref. [418] copyright © 2017 John Wiley and Sons.