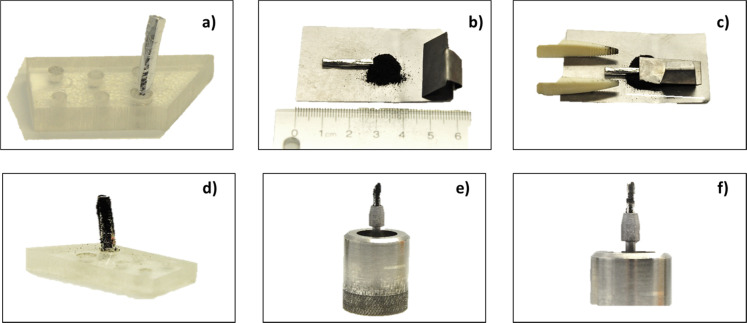

Figure 2.

Sample preparation procedure: (a) 2.3 mm × 2.3 mm × 18 mm high-purity indium pin used as a substrate and binder of the nanotube material; (b) pressing the setup consisting of the In pin, a tantalum sheet (40 mm square), plastic tweezers, an L-shaped tantalum sheet, and the CNT powder sample; (c) pressing the CNT powder onto the surface of the indium; (d) CNT powder sample pressed onto the surface of the In pin; (e) CNT/In pin mounted in a clean Ta chuck before analysis; (f) CNT/In pin mounted in a clean Ta chuck after sputtering for 120 min.