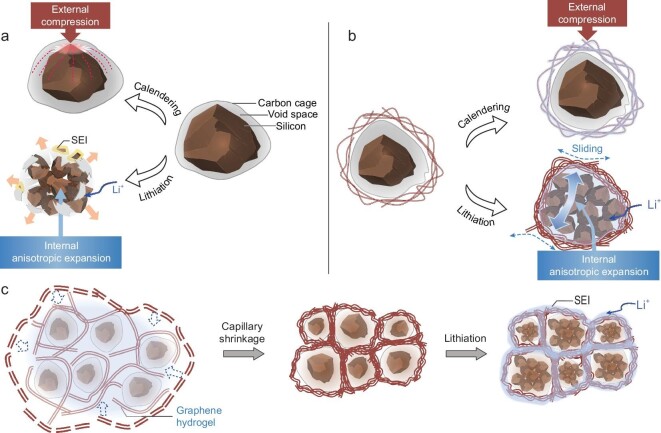

Figure 1.

Schematic of a highly imperfection-tolerant 3C-architecture design for microparticulate Si anodes. (a) SiMP@C, namely SiMPs in a highly graphitic carbon cage (normally prepared with a CVD procedure) with the predefined void that buffers pulverized Si nanoparticles. Such a SiMP@C is always ruptured under the high-pressure compression during calendering and the anisotropic expansion of irregular-sized SiMPs in electrochemical cycling. The exposed fresh Si surface induces severe side reactions, accumulating new SEI. (b) SiMP@C-GN, where the carbon cage (‘cell membrane’) is further stabilized and protected by a highly dense and robust graphene shell (‘cell wall’) inspired by the superior structural stability of a plant cell. The densely entangled graphene sheets can withstand the external compression, whereas their interlayer-sliding endows the imperfection-tolerance ability to manage the internal anisotropic expansion. (c) The formation of 3C architecture in SiMP@C-GN. SiMP@C is interwoven into the 3D graphene network with a hydrothermal process and the following capillary shrinkage (∼20 × volume shrinkage) allows crumple and densified graphene network tightly adhered to the surface of SiMP@C to yield the final SiMP@C-GN with dense and robust 3C architecture, forming a mechanically and electrically integrated structure with good imperfection-tolerance to repetitive volume variation during cycling.