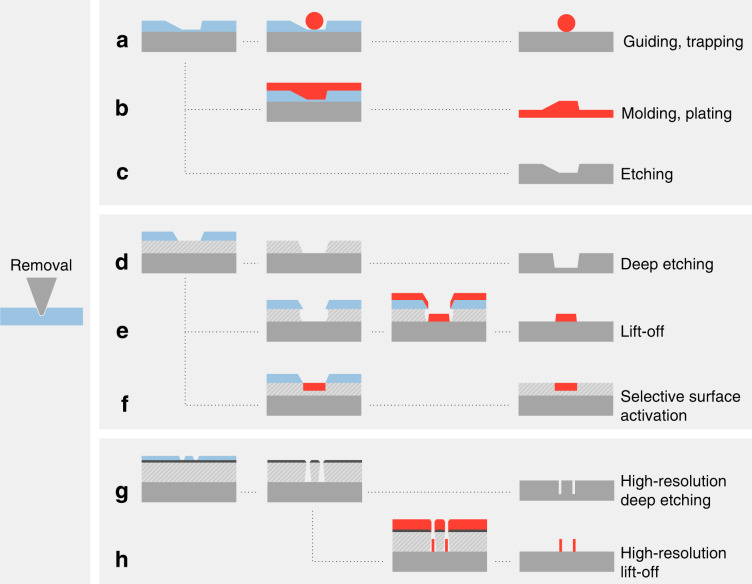

Fig. 3. Overview of relevant nanofabrication processes after local removal of a temperature-sensitive resist.

a 2D or 3D structures can directly serve as a biocompatible scaffold59 or be used to guide and trap nanoparticles56,57,58. After assembly, the PPA resist can be removed by heating55. b Molding of various soft transparent polymers directly from the patterned resist, as well as galvanic plating of metals, is possible31,60. c Direct use of the patterned resist as an etch mask allows etch transfer (wet or dry etch) of 2D and 3D features into various materials54,61,63–65. d A second layer under the temperature-sensitive resist can be used to amplify the final etch depth as well as for 3D features67,66. e A second organic layer under the temperature-sensitive resist that is selectively removed in wet chemistry can be used to create an undercut for lift-off68,69. f A functional layer under the temperature-sensitive resist can be locally accessed when the resist is removed and simultaneously activated by the thermal probe70–72 or in a subsequent step by oxygen plasma73. g A three-layer stack composed of a temperature-sensitive resist, a thin inorganic hard mask and an organic transfer layer is suitable for high aspect ratio and high-resolution etching29,43,69,74–76. h The three-layer stack can also be used for a high-resolution lift-off processes76,77