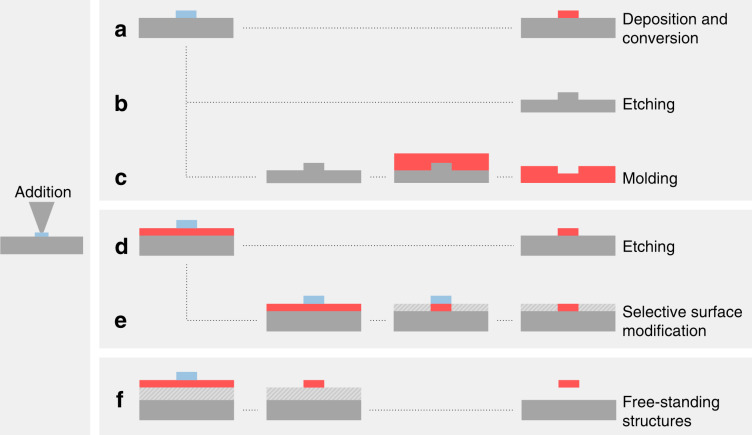

Fig. 7. Overview of relevant nanofabrication processes after addition of material to the sample from a heated tip.

a Direct deposition of a molten material108,111–116,127 or a loaded carrier matrix (e.g., polymer containing nanoparticles), which can be removed after the transfer117. b Direct deposition of a resist for dry etching into the substrate material118,121. c The etched structure can be used as a master for molding118. d Direct deposition of etch-mask nanostructures for a solvent free pattern transfer119,120. e Local functionalization of a low-dimensional material by selectively protecting certain areas with a nanoscale mask110. f Fabrication of free-standing nanostructures by dry etching into a first layer and subsequently removing of the sacrificial layer below122