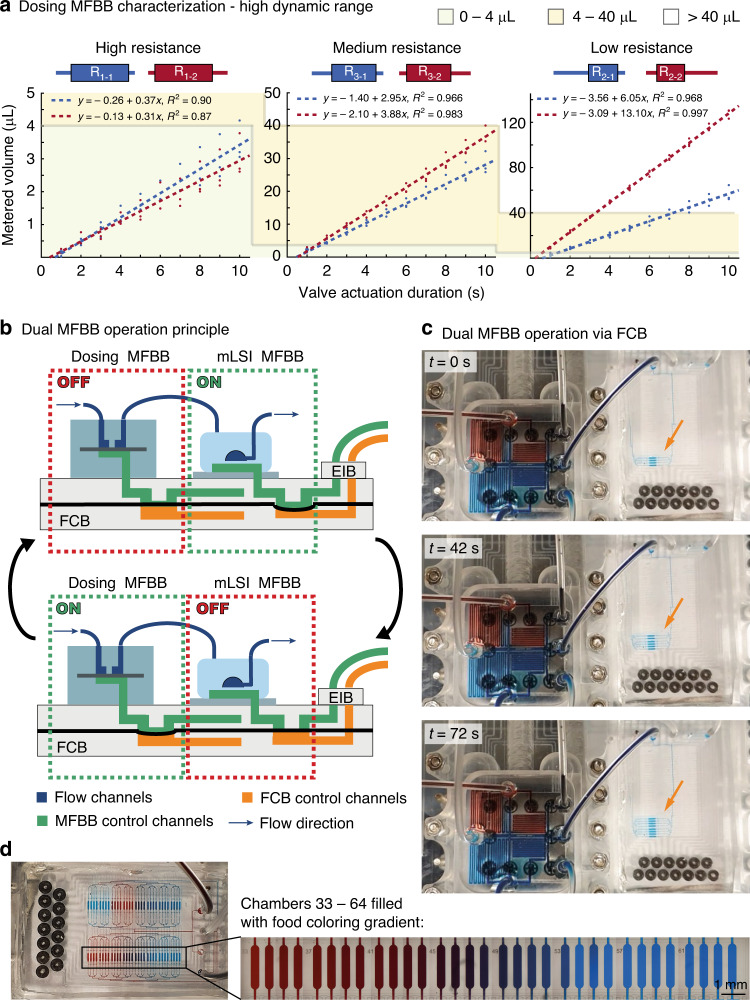

Fig. 6. Operation of two different MFBBs (a dosing and an mLSI MFBB) via the FCB.

a Dynamic range characterization of the dosing MFBB in terms of flow rate through the three hydraulic resistors at a pump pressure of 300 mbar. b Schematic of the dosing MFBB and the mLSI MFBB operated via the FCB. By sequentially enabling the MFBBs, the dosing MFBB can be used to fill the chambers of the mLSI MFBB. c Video frames showing the two MFBBs on the FCB and connected to each other with tubing. d Chambers of the mLSI MFBB filled with red or blue food coloring (which were selected in the dosing MFBB) or gradients generated by a long pulse of one food coloring followed by a long pulse of the other food coloring (chambers 33–64). The close-up view of chambers 33–64 consists of stitched brightfield micrographs