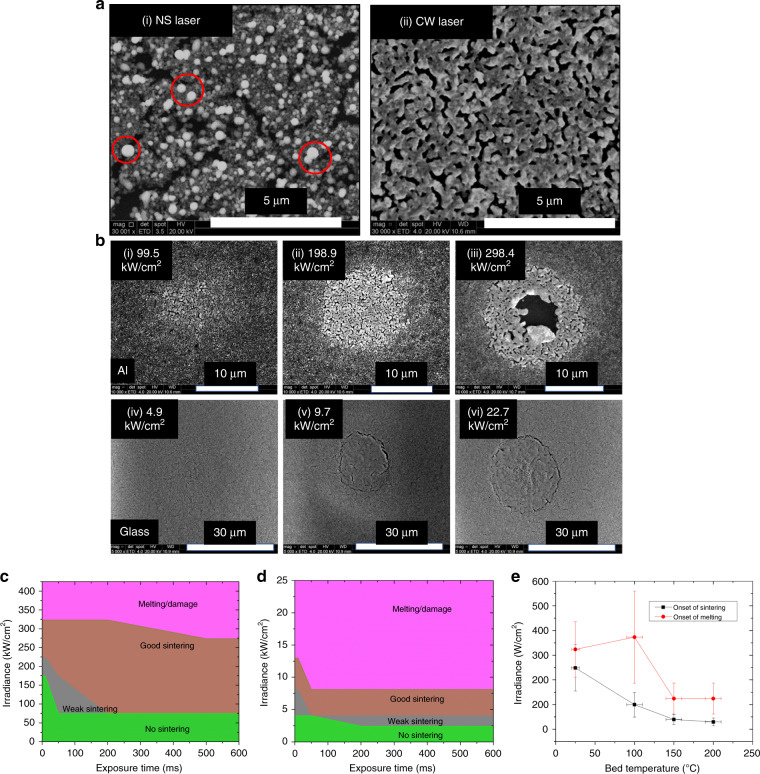

Fig. 4. Comprehensive study of laser-material interaction for Cu nanoparticles.

a Comparison of sintering quality using NS and CW lasers- (i) NS laser showing significant balling up effect (see red circled spots) with sporadic necking & crack developments (ii) CW laser showing no balling, uniform necking between particles throughout the spot area. b Variation in sintering quality of Cu NPs from no-sintering to weak sintering, good-sintering & melting as the irradiance of CW laser is increased for (i–iii) A 0.4 μm thick Cu layer on Al substrate for a 500 ms exposure duration (iv-vi) A 0.4 μm thick Cu layer on Glass substrate for 500 ms exposure. c A graph showing the laser irradiance vs exposure duration processing window for a 0.4um thick Cu NP layer on Al substrate. d Processing window for a 0.4 μm thick Cu NP layer on glass -substrate; experiments for Fig. 4a–d are conducted with particle bed at room temperature. e Reduction in sintering and melting onset threshold when using a heated bed at different initial temperatures.