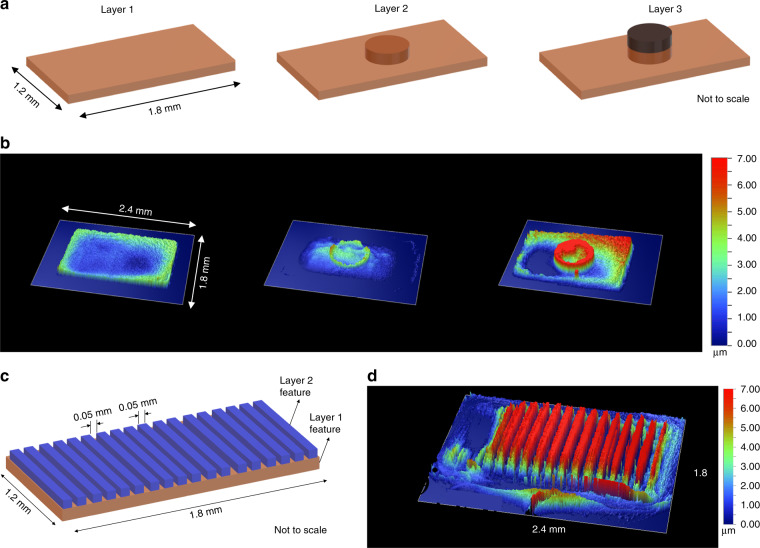

Fig. 8. Multilayer sintering of Ag nanoparticle inks.

a Visualization of the layer-by-layer (LbL) fabrication. The first layer is a 1.8 mm by 1.2 mm rectangular structure. A 500 μm circle is sintered on top of the first layer as part of the second and third layer. b Optical topographic images showing the LbL progression of the µ-SLS process. The RMS surface roughness are 2.24 μm, 1.19 μm and 4.08 μm Layers 1, 2 and 3 respectively. c Visualization of the two layer part with the first layer as a rectangular base and the second layer as a linear array. d Surface topography of the sintered and post-processed two-layer sample. The RMS height of the rectangular pillars measured from the top of layer 1 is 5.77 μm with a standard deviation of 1.75 μm. The averaged variability in pillar heights across the length of the array is 1.2 μm. These variations can be attributed to the non-uniformity in the layer deposition process, evolution of thermal gradients due to long exposure durations and the build-up of excess ink along the edges of the features during the sintering process.