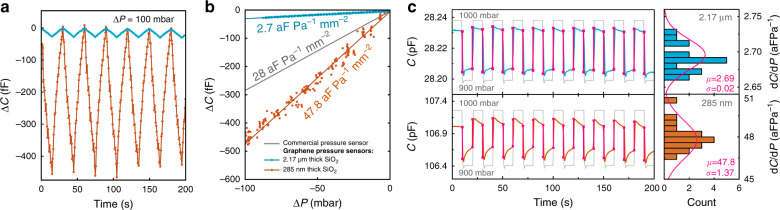

Fig. 6. Comparison of different capacitive pressure sensors.

a Triangular pressure wave applied to two graphene sensors with nm and m oxide thickness, showing the measured change in capacitance. The gas pressure is changed at a rate of mbar s−1. b Responsivity analysis of the chips at small using multiple periods of measured data from a as a function of the pressure change, and a comparison to a commercial capacitive pressure sensor (Murata SCB10H). c Analysis of the responsivity of the chips as determined from periodic pressure steps between and mbar. The gas pressure is changed at a rate of mbar s−1. Panels on the left: Blue line—measured capacitance of a graphene sensor with m. Orange line—measured capacitance of a sensor with nm. Thin gray line—applied time-dependent pressure profile. Magenta lines—extracted capacitance response of the sensors. Panels on the right: statistics over a number of cycles for both oxide thicknesses. The higher responsivity and larger gas leak rate of the nm device can account for the larger variations. Magenta lines—fit to a normal distribution, with the corresponding mean values and standard deviations in aF Pa−1 indicated