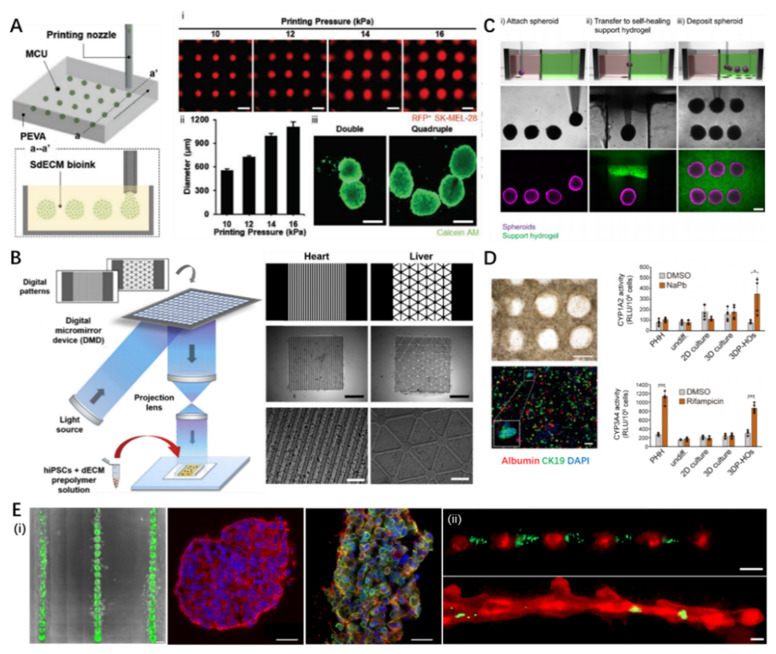

Figure 4.

Representative 3D bioprinted organoids and pharmaceutic applications. (A) The concept of in situ 3D bioprinting of cell aggregates and its potential for in situ printing of cancer organoids: (i) size control of spheroids by altering printing pressures; (ii) quantification of spheroids dimensions varied with printing pressure; (iii) stained images of double/quadruple melanoma organoids (scale: 500 μm). Reproduced with permission from [116], John Wiley and Sons, 2021. (B) Schematic and image demonstrating the 3D bioprinted spheroids in self-healing support hydrogels. Reproduced with permission from [117], Elsevier, 2019. (C) STL-based rapid 3D bioprinting process to fabricate dECM tissue constructs with tissue-specific iPSCs and biomimetically patterned heart and liver dECM tissue constructs. Reproduced from [121], Springer Nature, 2021. (D) 3D bioprinted hepatorganoids on day 10 and the P450-Glo assay of cytochrome activity (CYP1A2, CYP3A4) in the hepatorganoids after 7 days of differentiation. Reproduced with permission from [123], BMJ Publishing Group Ltd., 2021. (E) (i) 3D bioprinted patterned tumoroids and desired tumor cytokine expression (red: CK-8, green: CK-5, scale: 100 μm), (ii) alternative 3D bioprinting of MDA-MB-468 cells (green) and MCF-12A cells (red) at day 1 (up) and day 7 (down) demonstrating incorporation of cancer cells into the organoid (scale: 200 μm). Reproduced from [130], Scientific reports, 2019. STL, stereolithography; dECM, decellularized extracellular matrix; iPSCs, induced pluripotent stem cells.