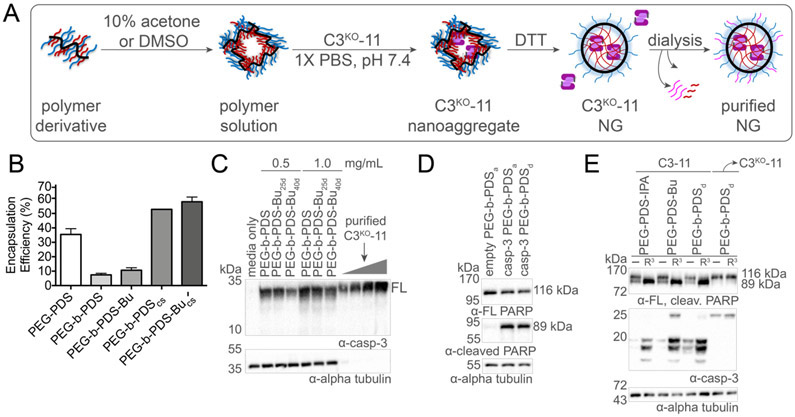

Figure 3. Co-solvent block copolymer NG formation.

(A) Co-solvent block copolymer nanogel (NG) formation begins by dissolving the polymer in 10% solvent followed by addition of an aqueous solution containing C3KO-11 dropwise with stirring. The general NG encapsulation, crosslinking and purification procedure is then followed. (B) Encapsulation efficiencies of the block copolymers is enhanced by the co-solvent methodology (cs subscript). (C) Visualization of PEG-b-PDS NG mediated delivery of C3KO-11 to MCF7 cells at two different doses (1.0 and 0.5 mg/mL polymer concentration). Purified C3KO-11 was added at 0.2, 0.4, 0.8 and 1.6 μg/mL. (D) PEG-b-PDS NG prepared using co-solvents acetone (a subscript) or DMSO (d subscript) mediated delivery of WT casp-3 demonstrated cleavage of poly (ADP-ribose) polymerase 1 (PARP) indicating delivery of active casp-3 WT and apoptosis with an empty NG control prepared using the co-solvent methodology. (E) Delivery of active C3-11 by PEG-PDS NG derivatives, unfunctionalized (−) and Arg3 (R3) functionalized, and resultant PARP cleavage. These data demonstrate C3KO-11’s ability to maintain activity against apoptotic substrates in cells and that R3 functionalization increased total protein delivered and subsequently increased the resultant PARP cleavage for various NG. Delivery of inactive C3KO-11 used as control to demonstrate lack of apoptosis from an inactive casp-3 cargo.