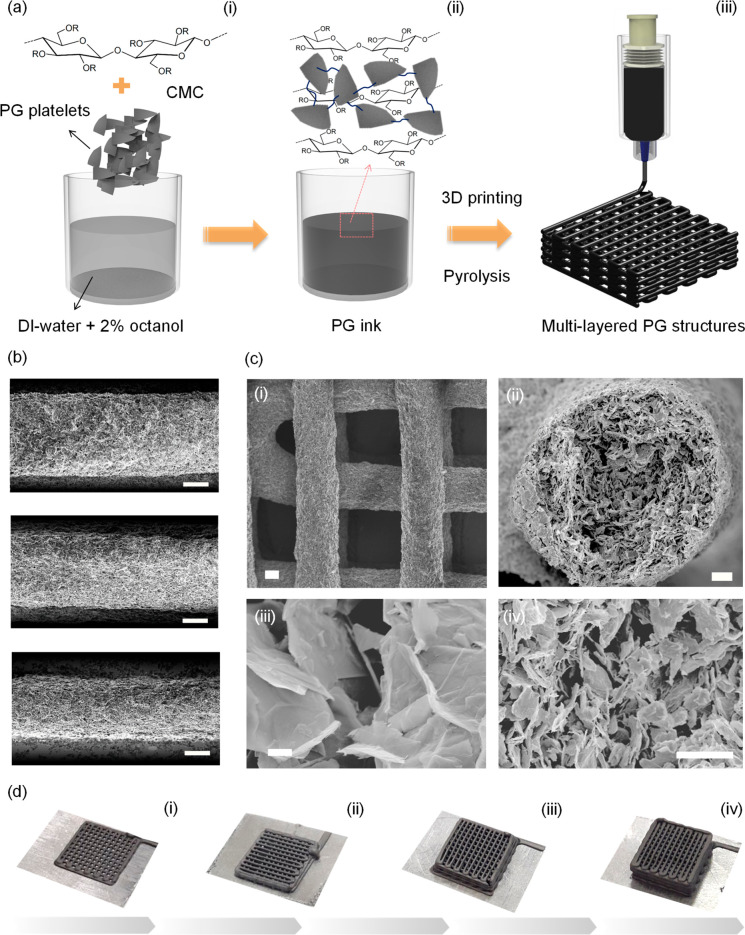

Figure 2.

a) Schematic showing the formulation and printing of the PG ink, (i) PG platelets are mixed with an aqueous solution of carboxymethyl cellulose (CMC) to which 1-octanol is added to form intersheet bridges; the dispersion is homogenized (ii) and 3D printed (iii) to fabricate woodpile and interdigitated electrodes. b) SEM images of printed PG lines obtained using nozzles of different diameters: 410, 250, and 200 μm (top to bottom, respectively), scale bars are 100 μm. c) SEM images of a woodpile electrode (i) and cross-section images of a printed strut at increasing magnification (ii)–(iv), scale bars are 100, 30, 20, and 1 μm, respectively. d) Pictures of woodpile electrodes (1 cm2 footprint area) presenting an increasing number of layers: 2 (i), 4 (ii), 6 (iii), and 8 (iv) layers.