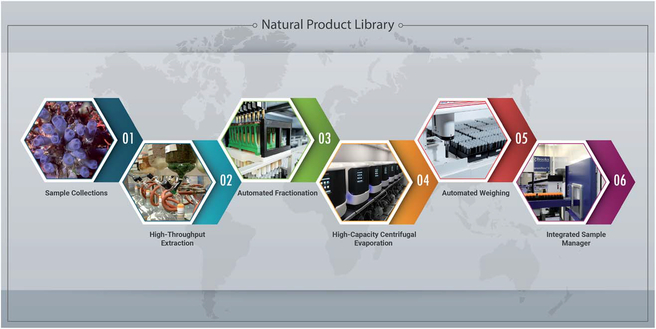

Fig. 2.

Overview of automated and high-throughput processes developed at the NCI National Program for Natural Products Discovery (NPNPD) to facilitate the production of a natural product-based screening library. (1) Since 1986, more than 80 000 samples have been acquired through collection agreements based on the NCI letter of collection with each participating source country or their representatives, which stipulates equitable benefit sharing from commercial products derived from discoveries made through these collections. (2) Extracts in the NCI NPR are prepared in a high-throughput manner using both an aqueous and organic solvent extraction process, resulting in two sequential extracts per collected specimen/sample.27 At present, the US National Cancer Institute’s (NCI) natural product repository contains over 230 000 unique extracts derived from plant, marine and microbial organisms. (3) Extracts (n = 88) are prefractionated on a customized Positive Pressure Solid Phase Extraction workstation (PPSPE) with two robotic arms working in parallel to produce seven fractions per extract (3.5 h; n = 616 fractions). (4) Fractions are dried using high-capacity centrifugal evaporation systems (18 h; n = 2304), and the final mass of each fraction is determined on an automated weighing station (5). (6) An automated sample management system with the capacity to store 1.1 million 2D-barcoded tubes (10 ml) is integrated with robotic systems designed to generate 384-well microtiter plates for HTS and 96-well plates for secondary HPLC-based fractionation of active primary fractions.