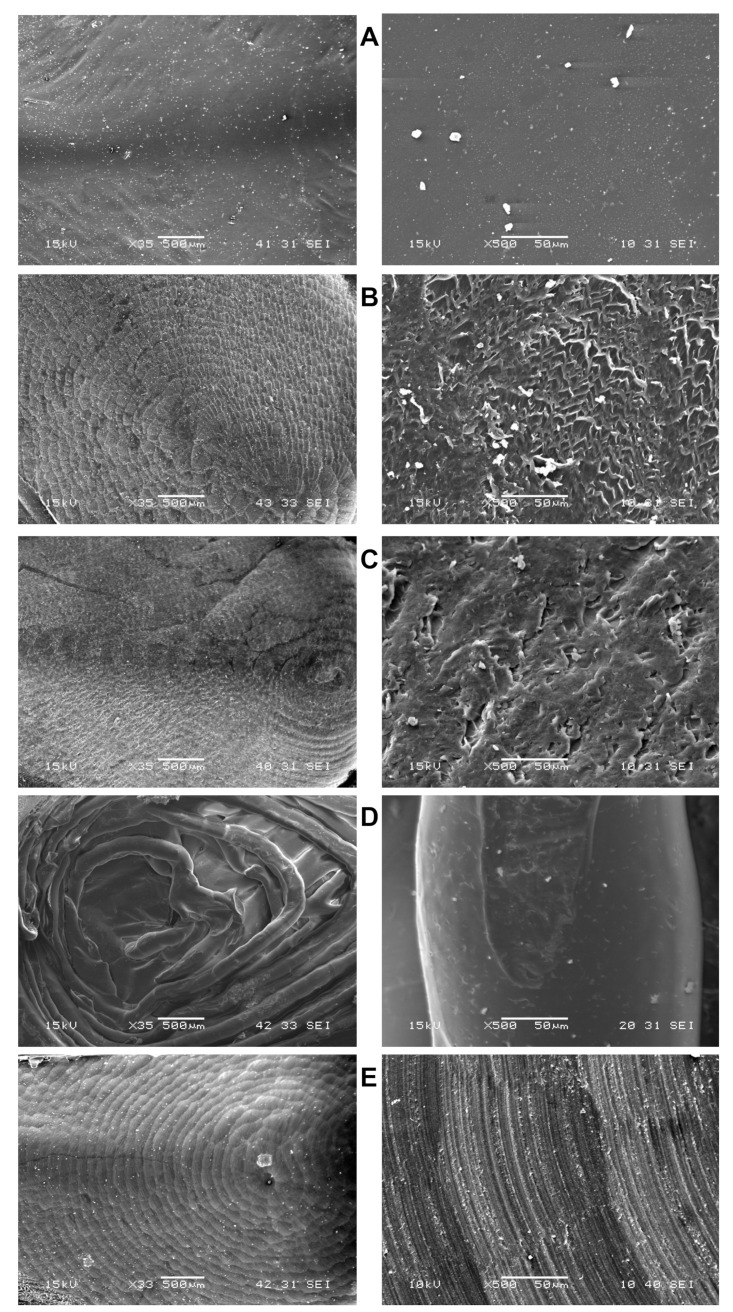

Figure 5.

Morphology of the crowns’ inner surfaces. (A): Prefabricated polycarbonate crown; (B): Milled polycarbonate crown (ZPF); (C): Milled polycarbonate crown (TBP); (D): 3D-printed polycarbonate crown; (E): Milled PMMA crown. The surfaces of prefabricated crowns were smooth. Concentric patterns were observed in the occlusal parts of CNC-manufactured crowns at magnification 35× (left column). In milling, these patterns are called scallops and are caused by stepover, i.e., the space between passes of ball nose end mills. At magnification 500× (right column), plastically deformed zones and small cracks were observed in milled polycarbonates, especially ZPF, and shallow parallel grooves were present on the surfaces of PMMA crowns.