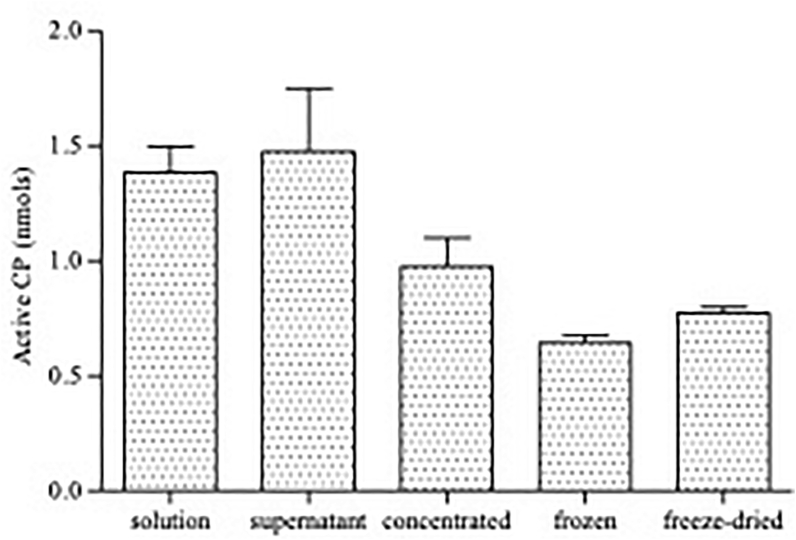

Figure 1.

Amount of CP enzyme activity at different stages of the processing and refinement of papaya latex from the original suspension to the final freeze-dried product. The solution was made by reconstitution of spray dried papaya latex with water at a ratio of 1:3 and was then centrifuged at 17,700 g at 4 °C to obtain the supernatant. Papaya latex supernatant (PLS) was then dialysed against polyethylene glycol to concentrate active CPs. The concentrated PLS was then frozen at-80 °C and frozen PLS was freeze-dried. Each point on the graph represents the amount of active CP present in 10μl. Error bars represent the standard errors of the means.