Table 1. Optimization of the Reaction Conditionsa.

| entry | [Cu] (X equiv) | ESF (Y equiv) | time (h) | yield (2a, %)b |

|---|---|---|---|---|

| 1c | CuO (2.0) | 2.0 | 20 | 20 |

| 2d | CuO (2.0) | 2.0 | 20 | 74 |

| 3 | CuO (2.0) | 2.0 | 20 | 89 |

| 4 | CuO (1.0) | 2.0 | 20 | 91 |

| 5 | / | 2.0 | 20 | trace |

| 6 | CuO (1.0) | 4.0 | 20 | 73 |

| 7 | CuO (1.0) | 1.5 | 20 | 70 |

| 8e | CuO (1.0) | 1.5 | 20 | 80 |

| 9f | CuO (1.0) | 2.0 | 20 | 87 |

| 10 | CuO (1.0) | 2.0 | 5 | N.D. |

| 11 | CuO (1.0) | 2.0 | 48 | 89 |

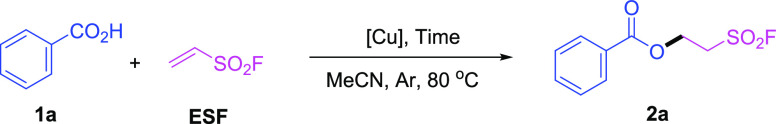

Reaction conditions: a mixture of benzoic acid (1a, 0.1 mmol), [Cu], ESF, and anhydrous MeCN (2 mL) reacted at 80 °C under argon atmosphere for the corresponding time.

The yields were determined by HPLC using 2a as the external standard (tR = 7.5 min, λmax = 229.9 nm, water/acetonitrile = 50:50 (v/v)).

In the air.

Undried MeCN (2 mL).

Reacted at 70 °C.

Reacted at 90 °C.