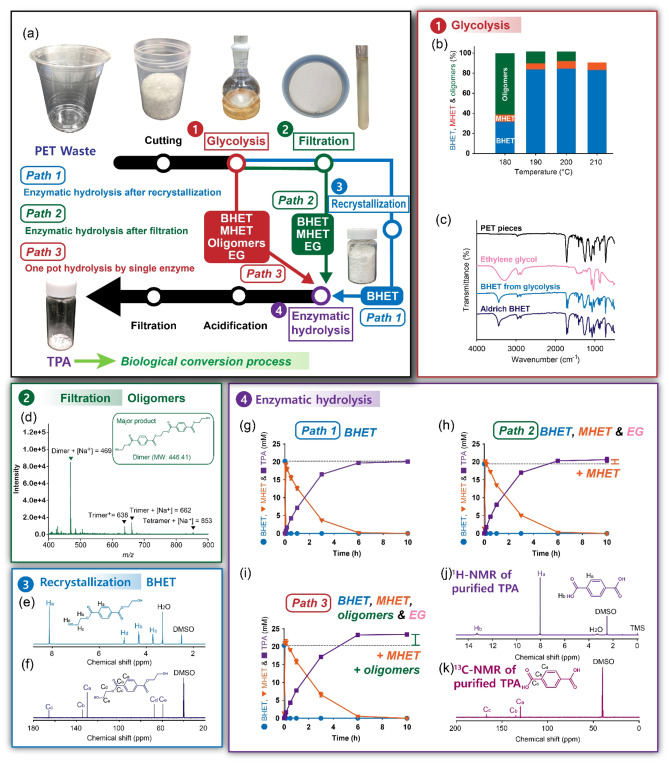

Figure 1.

Preparation of TPA from PET by a combination with glycolysis and enzymatic hydrolysis. (a) Three different PET‐to‐TPA hydrolysis pathways: (1) path 1 (enzymatic hydrolysis of pure BHET after crystallization), (2) path 2 (enzymatic hydrolysis of BHET mixture after filtration, (3) path 3 (enzymatic hydrolysis of BHET mixture without purification). (b) Temperature dependency of glycolysis. (c) FTIR spectra of the glycolyzed BHET in the PET‐to‐BHET conversion, reagent‐grade EG, BHET, and PET pieces. (d) Mass spectroscopy data of purified BHET after filtration. (e) 1H and (f) 13C NMR data of purified BHET after recrystallization. (g–i) Enzymatic hydrolysis profiles in paths 1–3, respectively. Among three different PET‐to‐TPA hydrolysis pathways, the one‐pot enzymatic hydrolysis of glycolyzed mixtures from path 3 without filtration and recrystallization achieves a high TPA yield (116.3 %). Paths 1–3 were performed at 30 °C and 1000 rpm in 100 mm sodium phosphate (pH 7.5) buffer for 10 h. The definition of enzyme unit used in this study is described in the Supporting Information.