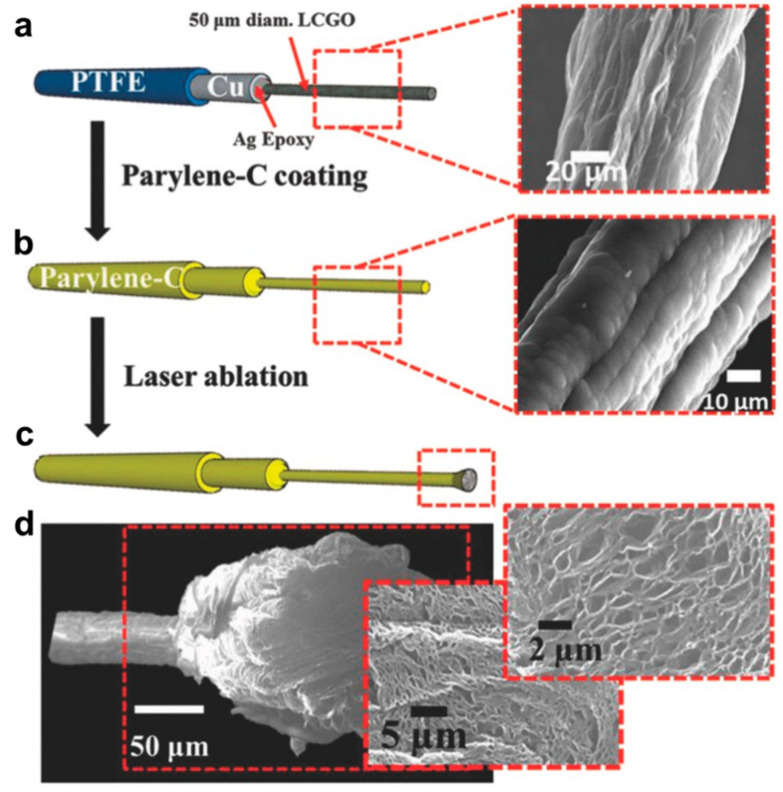

Figure 2.

Fabrication and imaging of LCGO brush electrodes. (a) The electrodes are attached to polytetrafluoroethylene-insulated copper wires with diameters of approximately 1 mm using conductive silver-based epoxy followed by (b) Parylene C coating. (c) Laser ablation at 250 mW opens the electrode end, creating a “brush” electrode. (d) Laser treatment produces an amorphous electrode with extraordinary surface roughness and porosity. Adapted from [11]. Copyright (2015), with permission from WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim.