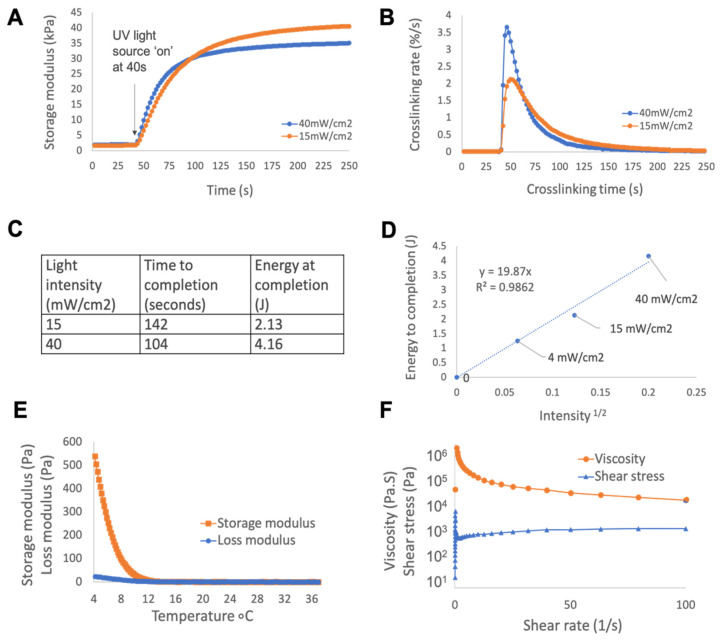

Figure A1.

Rheology data for 8% w/v GelMA/0.1% w/v LAP, performed at 4 °C unless otherwise specified. (A) To calculate crosslinking times of GelMA at 4 mW/cm2, the material was more rapidly crosslinked at 40 mW/cm2 and 15 mW/cm2 with the purpose of extrapolating the data to 4 mW/cm2. This was done to minimize the effect of condensation between the material and stage (a consequence of using a quartz plate to allow for in situ UV curing). (B) The relative reaction rates for these intensities were defined as the change in storage modulus per second as a percentage of the final modulus after 210 s of curing time, a timepoint chosen to approximate completion as it occurs well within the range of the graph approaching plateau. Energy to completion was defined as a relative reaction rate of <0.1%/s, which occurred at 142 s at 15 mW/cm2, and 104 s at 40 mW/cm2. (C) The energy to crosslink the material could then be estimated by multiplying time () by intensity (): . (D) Known relationships between light intensity and crosslinking rate were used to extrapolate this data: , where is the total energy, is the proportionality coefficient, is the intensity of light, and is the concentration of photoinitiator [47]. These energy values were plotted against to form a line of best fit through the origin. From this linear relationship, the energy required to crosslink GelMA at 4 mW/cm2 was 1.26 J. By applying , the minimum time thus required to crosslink GelMA at the desired 4 mW/cm2 was 314 s. To establish a safe margin ensuring the material was fully crosslinked, this timeframe was rounded up to 400 s and used for all subsequent UV-curing experiments at 4 mW/cm2. (E) Temperature analysis of non-crosslinked GelMA from 37 °C to 4 °C demonstrated a sol-gel transition at 15 °C. (F) The viscosity was then immediately assessed after cooling to reflect bioprinting conditions. The material exhibited typical shear-thinning properties at 4 °C.