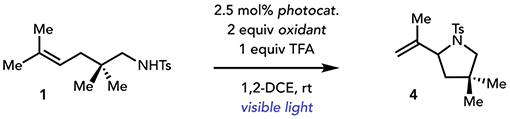

Table 1.

Optimization of Oxidative Amination

| |||

|---|---|---|---|

|

| |||

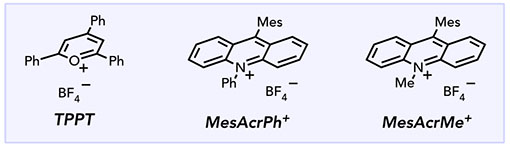

| entry[a] | photocat. | oxidant | % yield[b] |

| 1 | MesAcrPh+ | CuBr2 | 0% |

| 2 | MesAcrPh+ | Cu(OTf)2 | 3% |

| 3 | MesAcrPh+ | Cu(OAC)2 | 48% |

| 4 | MesAcrPh+ | CU(TFA)2 | 57% |

| 5 | MesAcrPh+ | Cu(OPiv)2 | 57% |

| 6 | MesAcrPh+ | CU(EH)2 | 87% |

| 7 | MesAcrMe+ | CU(EH)2 | 52% |

| 8 | TPPT | Cu(EH)2 | 24% |

| 9[c] | MesAcrPh+ | Cu(EH)2 | 28% |

| 10 | none | CU(EH)2 | 0% |

| 11 | MesAcrPh+ | none | 0% |

| 12[d] | MesAcrPh+ | CU(EH)2 | 0% |

| |||

Reactions conducted using 1 (0.1 mmol), oxidant (2 equiv), TFA (1 equiv), and photocatalyst (2.5 mol%) in degassed 1,2-DCE and irradiated with a 15 W blue LED flood lamp for 16 h.

Yields were determined by 1H NMR analysis of the unpurified reaction mixtures using phenanthrene as an internal standard.

Reaction conducted in absence of 1 equiv TFA.

Reaction vessel was covered in aluminum foil.