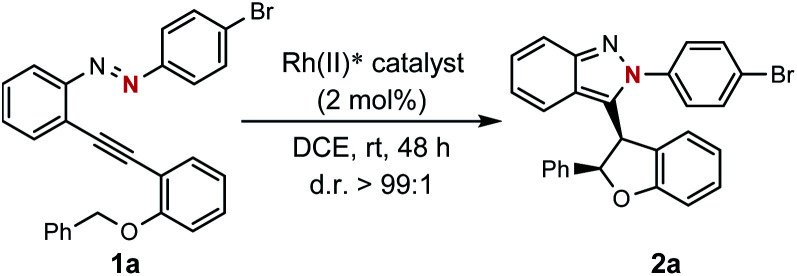

Optimization of reaction conditionsa.

| ||||

|---|---|---|---|---|

| Entry | Rh(ii)* | Solvent | Yieldb [%] | erc |

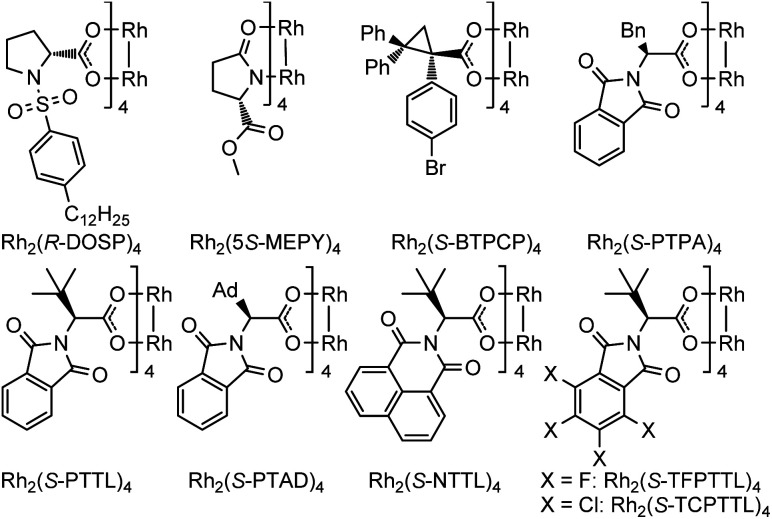

| 1 | Rh2(R-DOSP)4 | DCE | 56 | 29 : 71 |

| 2 | Rh2(5S-MEPY)4 | DCE | 17 | 50 : 50 |

| 3 | Rh2(S-BTPCP)4 | DCE | 61 | 8 : 92 |

| 4 | Rh2(S-PTPA)4 | DCE | 91 | 91 : 9 |

| 5 | Rh2(S-PTTL)4 | DCE | 86 | 97 : 3 |

| 6 | Rh2(S-PTAD)4 | DCE | 93 | 94 : 6 |

| 7 | Rh2(S-NTTL)4 | DCE | 92 | 96 : 4 |

| 8 | Rh2(S-TCPTTL)4 | DCE | 95 | 98 : 2 |

| 9 | Rh 2 (S-TFPTTL) 4 | DCE | 98 d | 98 : 2 |

| 10 | Rh2(S-TFPTTL)4 | DCM | 88 | 98 : 2 |

| 11 | Rh2(S-TFPTTL)4 | Toluene | 92 | 98 : 2 |

| 12 | Rh2(S-TFPTTL)4 | MeCN | 16 | 92 : 8 |

| 13 | Rh2(S-TFPTTL)4 | n-Hexane | 96 | 98 : 2 |

| 14e | Rh2(S-TFPTTL)4 | DCE | 65f | 96 : 4 |

| ||||

Unless otherwise noted, reactions were performed at 0.1 M in DCE using 0.20 mmol substrate and catalyst (2 mol%) under a N2 atmosphere.

Determined by 1H NMR spectroscopy.

The er value of 2a was determined by HPLC using a chiral stationary phase.

Isolated yields.

1 mol% catalyst was used.

25% starting material was recovered.