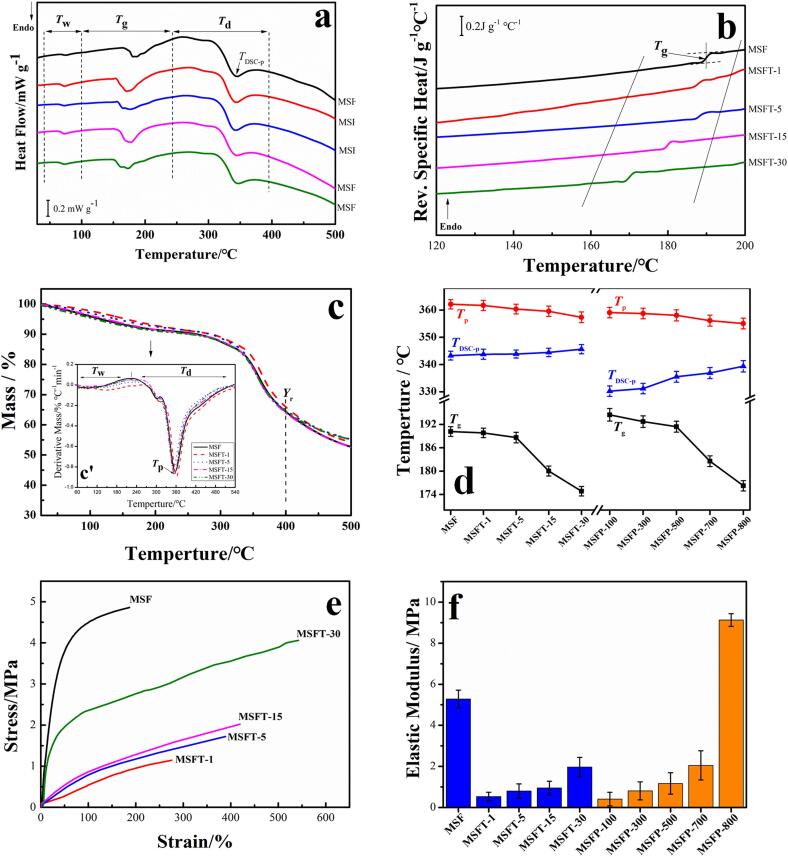

Fig. 2.

(a) Standard DSC curves of silk fibroin films with different ultrasonic time (0 ∼ 30 mins). Tw, Tg and Td represented the dehydration, glass transition and decomposition regions in standard DSC curve, respectively. (b) Reversing heat capacity measured from the modulating Step-Scan DSC curves of the samples with different ultrasonic time (0 ∼ 30 mins). (c) TG and DTG (inserted figure c’) analysis of SF films under different ultrasonic treatment (0 ∼ 30 mins). (d) The changing trend of Tg, TDSC-p and Tp of different SF films. Tg and TDSC-p represented glass transition temperature and decomposition peak temperature from DSC measurement, and Tp is the temperature at the maximum weight loss rate of the sample from DTG curve. (e) Stress–strain curves of SF films under different ultrasonic treatment (0 ∼ 30 mins). (f) Elastic modulus of SF films as a function of ultrasonic time (0 ∼ 30 mins; MSF, MSFT-1, MSFT-5, MSFT-15 and MSFT-30) and ultrasonic intensity (100 ∼ 800 W; MSFP-100, MSFP-300, MSFP-500, MSFP-700 and MSFP-800). Each sample was immersed in water for 20 min prior to DMA testing.