Abstract

Emission measurements are available in the literature for a wide variety of field burns and laboratory experiments, although previous studies do not always isolate the effect of individual features such as fuel moisture content (FMC). This study explores the effect of FMC on gaseous and particulate emissions from flaming and smouldering combustion of four different wildland fuels found across the United States. A custom linear tube-heater apparatus was built to steadily produce emissions in different combustion modes over a wide range of FMC. Results showed that when compared with flaming combustion, smouldering combustion showed increased emissions of CO, particulate matter and unburned hydrocarbons, corroborating trends in the literature. CO and particulate matter emissions in the flaming mode were also significantly correlated with FMC, which had little influence on emissions for smouldering mode combustion, when taking into account the dry mass of fuel burned. These variations occurred for some vegetative fuel species but not others, indicating that the type of fuel plays an important role. This may be due to the chemical makeup of moist and recently live fuels, which is discussed and compared with previous measurements in the literature.

Keywords: flaming, smouldering, wildland fuel, fuel moisture content, emissions, steady state, combustion

Introduction

Wildland fires emit a mixture of gaseous and particulate emissions during combustion that impacts the health of first responders, nearby populations and the earth-climate system. Recent studies have shown both short- and long-term health effects from these emissions (Adetona et al. 2016), in particular to the pulmonary and cardiovascular systems (Rappold et al. 2011; Unosson et al. 2013; Reid et al. 2016). In addition, earth-climate simulations rely on estimates of global carbon production from fires (Seiler and Crutzen 1980). Numerous studies have quantified emissions from wildfires, prescribed fires (Ward and Hardy 1991; Reinhardt and Ottmar 2000, 2004; Reisen et al. 2011) and smaller-scale laboratory experiments (Freeborn et al. 2008; Burling et al. 2010). Ward (1983) developed a model for predicting particulate matter emission rates as a function of fireline intensity and flame length for prescribed fires. Freeborn et al. (2008) measured a wide range of effluents from flaming laboratory fires of numerous fuels with fixed fuel moisture content (FMC). Reinhardt and Ottmar (2000, 2004) tracked time-averaged exposure of gases and particulates to wildland firefighters operating on several tasks in the field, finding the highest exposure levels during prescribed fires, most likely due to increased FMC and smouldering conditions. Effluents measured included benzene, acrolein, formaldehyde, CO, CO2, respirable particulate matter (PM) and total particulate matter (TPM). Despite higher levels measured during prescribed fires, all measurements were still determined to be within permissible levels, even though wildland firefighters do not generally wear respiratory protection (Reinhardt and Ottmar 2000, 2004). Fuels in the field ranged from completely live to dead, with modified combustion efficiency (MCE) ranging from 75% to 95% (Urbanski 2014).

It is well known that smouldering and flaming combustion dramatically differ in emissions behaviour; however, there are few studies addressing changes in emissions for different burning conditions such as changes in fuel type, FMC and mode of combustion. Within similar fuel types, fuel arrangement and moisture content are known to strongly influence resulting emission factors (EFs) (Mobley et al. 1976). Chen et al. (2010) studied the effect of moisture content on emissions from litter, duff, soil and aboveground shrub vegetation in laboratory-scale experiments. They first completely dried the fuels and then re-wetted them to obtain a desired moisture content. They concluded that the overall combustion efficiency decreases as the FMC increases. They also saw change in EFs as the FMC changed, but no prominent trend was reported. May et al. (2019) performed a laboratory examination of the effect of FMC on sugar gum eucalyptus (Eucalyptus cladocalyx), mountain laurel (Kalmia latifolia) and northern bayberry (Myrica pensylvanica). Laboratory experiments of fire spread over a 1 m2 test surface showed that FMC had a drastic impact on production of PM, CO and CO2. It was hypothesised that some of this was due to the presence of volatile oils in recently-live, moist samples, especially eucalyptus. Using a cone calorimeter, Possell and Bell (2013) also showed a large effect on emissions with changes in FMC of eucalyptus. Emission factors of CO and PM were observed to correlate with decreasing FMC, though the peak heat-release rate (HRR) increased. Hayashi et al. (2014) performed experiments on the residue of three cereal crops, that is, rice, wheat and barley at two moisture contents (dry and wet) and measured gas and particle emissions from open burning. They saw differences in emissions and combustion conditions with crop type, as wheat straw underwent long-duration smouldering, whereas rice and barley straw underwent long-duration flaming. They concluded an increase in carbon species emitted occurred with an increase in FMC; similar results were also found for loblolly needle beds burned in the laboratory (Mobley et al. 1976).

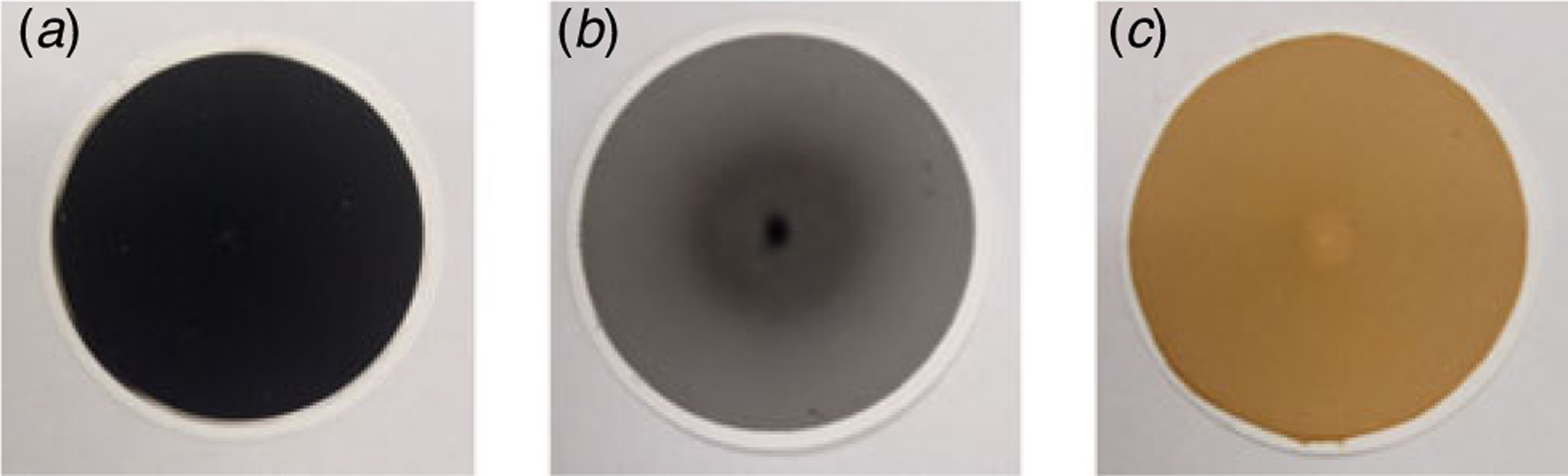

The effect of FMC on smouldering combustion has been well studied for peat fires (Hu et al. 2019a, 2019b) and organic soils (McMahon et al. 1980) due to their large production of effluents, impacts on health and extended burning durations. Hu et al. (2019a) performed experiments at eight different FMCs and showed that peat can self-sustain smouldering combustion with FMC as high as 61%1. McMahon et al. (1980) performed laboratory-scale experiments on wet (~75% FMC) and dry (~6.63% FMC) soil samples and found very low emissions of NOx. PM emissions during smouldering combustion were particularly high, which is important as PM can lead to various respiratory and cardiovascular diseases (Rappold et al. 2011; Unosson et al. 2013). PM emissions were measured for different size ranges by Hu et al. (2019a, 2019b) using a staged cascade impactor. Variations in the production rate of PM were observed for different FMC under the same burning conditions. Hu et al. (2019a, 2019b) also observed different particles, namely blackish carbon particles during flaming combustion and a yellowish haze during smouldering combustion, which is characteristic of haze aerosols from wildland fire smoke with diameters less than 1 μm. (McMahon et al. 1980) also found a similar bright yellow colour on the glass fibre filters designed to capture particulates from experiments and reported that they were most likely oil droplets from smouldering combustion, concluding no soot particles were evident. None of the aforementioned studies performed a detailed analysis on the filters to identify the chemical compounds present.

Estimating emissions of various effluents from wildland fires typically involves two steps. First, the amount of biomass consumed out of the total available biomass is calculated, often termed fuel consumption (Urbanski 2014). The amount of effluent produced is then estimated using an emission factor, which represents the mass of species emitted (g) per unit mass of dry fuel consumed (kg). Although this representation only provides time-averaged results, it is a useful framework that can be utilised alongside time-varying measurements here.

Emission factors are strongly dependent on burning conditions, moisture content and the type of fuel (May et al. 2019). The fuel moisture content (Smith et al. 2013) is defined based on the wet mass, MW, versus dry mass, MD, of the sample:

| (1) |

In essence, this represents the percentage of the fuel mass that is either water or other liquid compounds that are evaporated when determining the dry fuel mass. Note that the definition of FMC differs from the definition sometimes used in wildland fire studies, where FMC can vary between 55% and 180% (Hu et al. 2019a, 2019b). To distinguish different modes of combustion, such as flaming and smouldering, a modified combustion efficiency is often used:

| (2) |

where it is assumed that ΔCO2 and ΔCO are the excess concentrations of CO and CO2. A full mass balance including all carbon-based species would be ideal; however, it has been found this simplified version works well to distinguish modes of combustion, because CO and CO2 are the primary effluents by mass (>94%) (Ward and Hao 1991).

Recent studies (Butler et al. 2020; Weise et al. 2020a, 2020b) have shown that emission data are multivariate and relative in nature as the amount of mass burned and released (in terms of smoke emissions, residual char and ash) are fixed by conservation of mass. They propose a new Compositional Data Analysis (CoDA) technique that considers the relative nature of data, which is ignored in commonly used statistical techniques in the literature. However, the present study is performed on a custom-made linear tube-heater apparatus, and it becomes important to compare and validate the results with literature where traditionally statistical techniques are used. So, in this study, data is expressed as an average ± standard deviation between averages from different experiments.

A selected set of chemical species have been examined in this study, including carbon-based species, oxygen (O2), nitrogen oxide (NO), nitrogen dioxide (NO2), oxides of nitrogen (NOx), sulfur dioxide (SO2) and unburnt hydrocarbon (HC). Four of these (CO, PM, SO2 and NO2) belong to the six ‘criteria air pollutants’ as identified by the United States Environmental Protection Agency (EPA).

Experimental setup

Fuels and moisture content

Four fire-prone species were chosen for testing: lodgepole pine (Pinus contorta Douglas ex Loudon), Douglas-fir (Pseudotsuga menziesii (Mirb.) Franco), mountain laurel (Kalmia latifolia) and pitch pine (Pinus rigida Mill.). These species were selected because of their availability and prevalence in fire-prone ecosystems. Lodgepole pine and Douglas-fir were shipped from Missoula, Montana, providing a representation of wildland fires in western United States forests. Mountain laurel and pitch pine were shipped from New Jersey, with the Pine Barrens there representing a subset of fires in oak pine forests of the United States.

Fuels were picked live from trees, placed in sealed plastic bags and shipped overnight to the University of Maryland. Samples were immediately placed in a refrigerator to avoid decomposition until experiments were performed. Samples were prepared so that continuous flaming conditions could be reached during testing. Lodgepole and pitch pine needles were cut into ~3 cm segments. Mountain laurel leaves were crushed before testing, and Douglas-fir needles were burned without any further processing.

Three different drying conditions were investigated, referred to as ‘live’, ‘wet’ and ‘dry’, based on the duration of drying before testing (0 h, 3 h and 72 h respectively), resulting in ~52.9% ± 4.20%, 11.9% ± 1.43% and 2.88% ± 0.91% FMC respectively, where the error range represents the standard deviation between different test averages. Leaves and needles were first removed from branches to form a single layer over a perforated aluminium tray and placed in a laboratory convection oven at 70°C for approximately the duration noted earlier. It is hypothesised that the loss of volatile constituents mainly depends on drying parameters and, by using a lower drying temperature, a wet condition is achieved such that it retains some, but not all, volatiles and other characteristics of live fuels (Rahimmalek and Goli 2013; Jervis and Rein 2016; Matt et al. 2020). Towards the end of the drying duration, a subset of samples was removed, and their moisture content was analysed using an A&D MF-50 moisture analyser, which rapidly heats samples over a micro-balance using a quartz heater. FMC was continuously checked on multiple samples before testing.

Apparatus and instrumentation

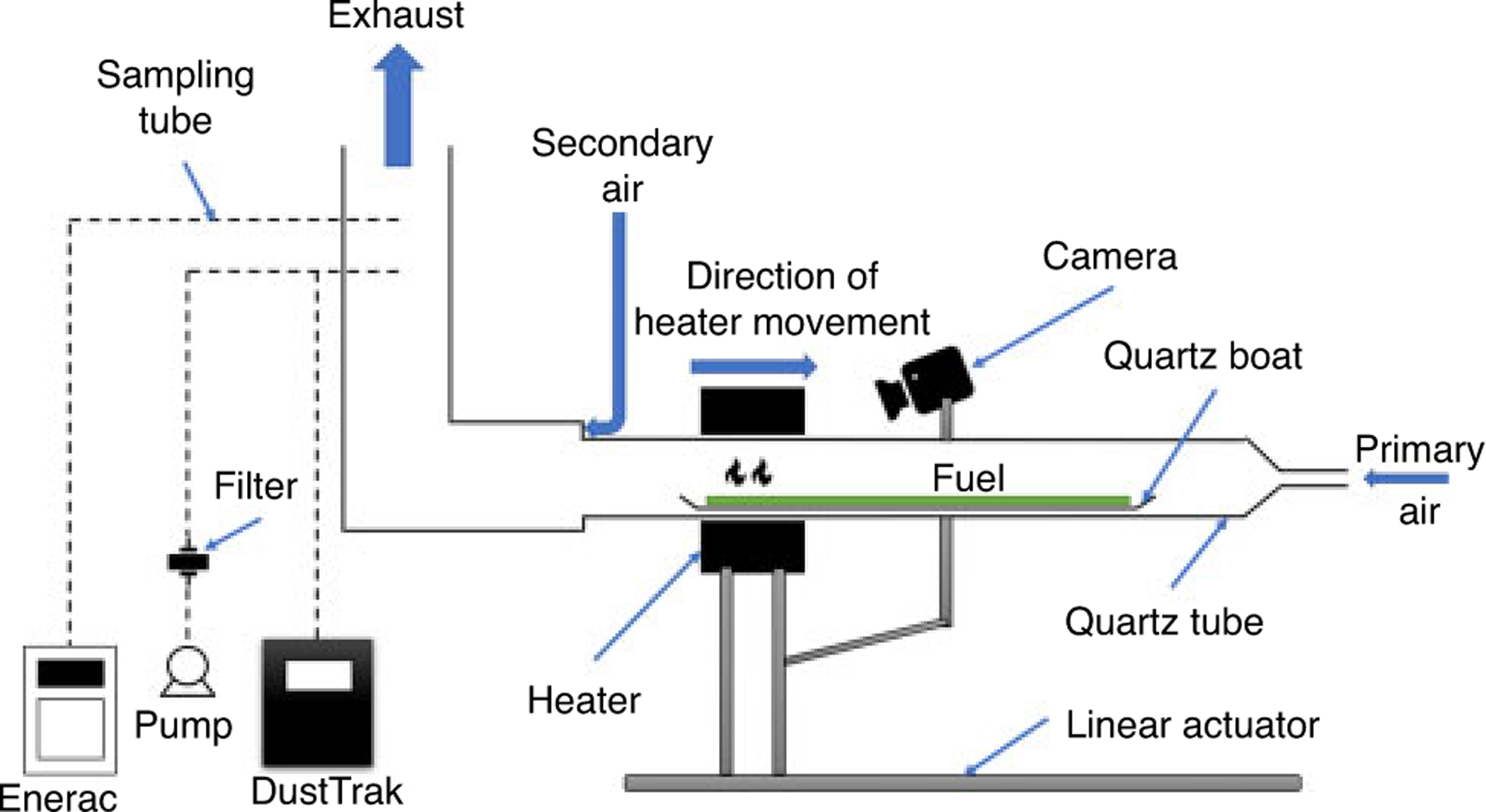

Combustion of wildland fuels was conducted in a custom-made linear tube-heater apparatus based on DIN 53436 (Einbrodt et al. 1984; Prager 1988), shown in Fig. 1. This apparatus is relatively new for wildland fuels and consists of a 182 cm long quartz tube with an inner diameter of 3.5 cm and a narrow, annular ceramic heater with a length of 15.2 cm and an inner diameter of 7.6 cm. The ceramic heater surrounding the quartz tube was mounted on a Velmex linear actuator that moved along the outside of the quartz tube at a controllable speed. The heater travelled in the direction opposite to the primary airflow in the tube (counter-current direction), and it was employed with the lowest heating rate that exhibited continuous flaming without preheating the upstream fuel throughout the test duration. Moreover, the traverse rate of the heater was determined after performing several preliminary experiments at each condition such that it did not accelerate the burning process of the fuel. A similar experimental setup was used recently (Kim et al. 2018); however, the heater was travelling in the same direction as the primary airflow (co-current direction), resulting in mixed flaming and smouldering combustion, potentially re-burning pyrolysed fuels in the flaming mode. DIN 53436 was designed to provide a continuous and constant concentration of species over a long duration of time (>60 min), a condition that is unachievable in the steady-state tube furnace (Stec et al. 2008). The electrically heated ceramic can reach a temperature as high as 1200°C; controllable using a K-Type thermocouple placed adjacent to the ceramic heater. The temperature was set in the range of 450–475°C for smouldering and in the range of 625–650°C for flaming experiments. After combustion, heating tape set to 100°C was placed over the quartz tube, minimising deposition of particulates on the tube.

Fig. 1.

Schematic diagram of the linear tube-heater smoke generator apparatus.

Conditions such as the amount of fuel, airflow, operating temperature and translation speed were optimised to achieve fully flaming or smouldering combustion for each test condition (see Table 1). The fuel was evenly distributed along the 80 cm long quartz boat, which was then placed in the quartz tube. One end of the quartz tube was supplied with dry air and the other end was attached to a 7.62 cm diameter steel exhaust port, where emissions were diluted using secondary air before leaving to the exhaust. Both primary and secondary airflow rates were controlled using Alicat flow controllers; flow rates varied depending on burning conditions (see Table 1). A stainless-steel sampling tube, 9.24 mm inner diameter with 2 mm holes spaced 12.7 mm apart along the length, was inserted through the diameter of the steel exhaust, ensuring enough length for fully-developed flow and mixing. Effluents were drawn from both ends of the sampling probe by a 6.35 mm tubing connected to the diagnostic instrument. Due to the low saturation limits of the instruments, the smoke was diluted a third time before analysis of smouldering experiments.

Table 1.

Control parameters for continuous flaming and smouldering experiments

| Fuel | Airflow (L min−1) | Amount of fuel (g) | Heater rate (cm min−1) | |||

|---|---|---|---|---|---|---|

| Primary | Secondary | Flaming | Smouldering | Flaming | Smouldering | |

| DF | 3 | 15 | 15 | 7.5 | 3 | 2 |

| LPP | 3 | 12 | 15 | 7.5 | 3 | 2 |

| PP | 3 | 15 | 10 | 5 | 3 | 2 |

| ML | 3 | 15 | 10 | 5 | 3 | 2 |

DF, Douglas-fir; LPP, lodgepole pine; PP, pitch pine; ML, mountain laurel

Four different diagnostic techniques were used. An Enerac 700 provided real-time concentrations of oxygen (O2), nitrogen oxide (NO), nitrogen dioxide (NO2), oxides of nitrogen (NOx) and sulfur dioxide (SO2) using an electrochemical sensor and the concentrations of carbon dioxide (CO2), carbon monoxide (CO) and unburnt hydrocarbons (HC) using a nondispersive infrared (NDIR) sensor, which was calibrated against propane for the concentration of HC, all with an acquisition frequency of 1 Hz. The internal pump flow rates were set at 1.5 L min−1 and 1 L min−1 for flaming and smouldering conditions respectively. A DustTrak DRX Model 8534 with a concentration range of 0.001–150 mg m−3 and a flow rate of 3 L min−1 was used for real-time measurements of PM with an acquisition frequency of 1 Hz. Although the device could distinguish different size ranges (e.g. PM1, PM2.5, PM10 and TPM), little variation was observed, so only TPM has been reported. Gravimetric analysis was performed to calibrate readings from the DustTrak and to provide time-averaged PM using a 0.8 μm pore size mixed cellulose ester filter placed in a 37 mm filter cassette, connected to the pump running at 2 L min−1. Experiments were continuously recorded using a GoPro camera to help explain sudden peaks in PM and CO, often attributed to a transition between smouldering and flaming. Numerous preliminary experiments were conducted to characterise the experimental setup and achieve a continuous flaming condition. The amount of fuel and the heater speed were varied for different fuels and FMC to achieve continuous flaming, as reported in Table 1. Gas sampling for all experiments were repeated four times: two times alongside a filter cassette and two times with a DustTrak. Caution was applied not to cause the Enerac 700 to switch from a low range to a high range during testing, which would result in data loss, or to over-saturate the DustTrak beyond 150 mg m−3. Any saturated data, which amounted to a small fraction of what was recorded in any one experiment, was removed during post processing. This process did not appreciably affect the reported results.

Results

Time-dependent burning process

Time-dependent concentrations of gaseous emissions from representative tests of flaming Douglas-fir at 10% FMC are shown in Fig. 2. Emissions remain relatively constant throughout the test duration, with a small increase in CO and a very small decrease in TPM over time. The former is possibly due to the time required to achieve steady-state conditions, and the latter due to deposition onto the quartz tube. CO and CO2 are clearly the primary effluents with smaller contributions of HC, NOx and SO2. HRR is also shown, calculated using CO2 production (see Janssens 2016) due to its greater sensitivity than O2 measurements. Other fuel types similarly emitted a constant concentration of gaseous emissions with time; average values from these tests are reported in Table 2.

Fig. 2.

Average concentrations of CO (ppm/10), CO2 (%), HC (ppm), NOx (ppm/10), SO2 (ppm), HRR (W/10) and TPM (mg m−3) from 10% FMC Douglas-fir emissions as measured directly out of the quartz tube. Note the use of %, ppm and scaling by a factor of 10 in order to highlight all species on one graph.

Table 2.

Concentrations, MCE and EFs for different fuel types under both flaming and smouldering combustion conditions

| Flaming | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Average concentration | Emission factors (g kg−1) | ||||||||||||

| Sample | MCE | TPM (mgm−3) | CO (ppm) | CO2 (%) | HC (ppm) | NOx (ppm) | SO2 (ppm) | HRR (W) | TPM | CO | CO2 | NOx | SO2 |

| DF – L | 97.3±0.85 | 57.8±3.78 | 2091±536 | 7.74±0.48 | 0 | 154±38.2 | 5.82±2.82 | 562±33.0 | 0.63±0.06 | 27.3±5.23 | 1592±88.0 | 2.29±0.37 | 0.15±0.07 |

| DF – W | 99.4±0.43 | 114±35.9 | 655±41 | 12.2±0.18 | 1.68±2.10 | 225±6.72 | 28.3±8.70 | 883±15.1 | 0.79±0.17 | 4.68±0.29 | 1372±23.1 | 1.72±0.05 | 0.39±0.12 |

| DF – D | 99.1±0.28 | 168±48.3 | 1119±357 | 12.8±0.78 | 14.0±15.5 | 196±31.3 | 27.8±14.7 | 929±57.7 | 0.46±0.29 | 7.20±2.30 | 1298±76.3 | 1.38±0.22 | 0.35±0.19 |

| PP – L | – | – | – | – | – | – | – | – | – | – | – | – | – |

| PP – W | 99.2±0.27 | 107±20.7 | 819±275 | 10.08±2.28 | 0 | 219±32.8 | 15.4±12.0 | 730±1.8 | 0.98±0.19 | 8.66±2.95 | 1683±18.6 | 2.63±0.38 | 0.32±0.25 |

| PP – D | 99.3±0.12 | 119±1.62 | 733±132 | 10.82±12.5 | 11.8±13.6 | 225±36.3 | 13.7±15.5 | 785±3.48 | 0.99±0.01 | 7.15±1.25 | 1670±105 | 2.47±0.41 | 0.26±0.30 |

| LPP – L | 97.9±0.98 | 50.0±0.75 | 1030±100 | 6.40±0.05 | 0 | 144±15.4 | 10.7±4.35 | 462±3.4 | 0.72±0.01 | 15.6±1.62 | 1530±138 | 2.52±0.17 | 0.33±0.17 |

| LPP – W | 99.5±0.30 | 117±14.8 | 456±18.7 | 11.9±0.05 | 0 | 257±6.75 | 28.5±4.85 | 720±4.65 | 1.13±0.68 | 3.21±1.31 | 1320±8.32 | 1.95±0.05 | 0.39±0.07 |

| LPP – D | 99.6±0.02 | 68.5±15.6 | 544±30.1 | 12.9±0.15 | 0 | 256±8.95 | 38.9±2.20 | 785±10.6 | 0.38±0.16 | 3.50±0.20 | 1316±17.5 | 1.77±0.06 | 0.49±0.03 |

| ML – L | – | – | – | – | – | – | – | – | – | – | – | – | – |

| ML – W | 99.4±0.03 | 26.8±1.98 | 554±30.7 | 9.36±0.06 | 0 | 220±36.2 | 24.5±3.36 | 675±3.30 | 0.24±0.02 | 5.97±0.28 | 1594±45.5 | 2.65±0.61 | 0.52±0.08 |

| ML – D | 99.5±0.03 | 95.6±46.8 | 511±16.3 | 9.42±0.60 | 0 | 245±19.5 | 20.3±3.18 | 681±47.2 | 0.81±0.40 | 5.06±0.16 | 1476±100 | 2.78±0.23 | 0.39±0.06 |

| Smouldering | |||||||||||||

| Average concentration | Emission factors (g kg−1) | ||||||||||||

| Sample | MCE | TPM (mgm−3) | CO (ppm) | CO2 (%) | HC (ppm) | NOx (ppm) | SO2 (ppm) | HRR (W) | TPM | CO | CO2 | HC | NOx |

| DF – L | 77.6±1.22 | 1525±21.12 | 4481±844 | 1.56±0.18 | 383±58.7 | 64.8±29.9 | 0 | 128±17.0 | 47.7±0.61 | 172±17.4 | 940±29.0 | 23.6±1.55 | 3.34±1.17 |

| DF – W | 81.9±0.05 | 2203±88.7 | 6833±645 | 3.12±0.30 | 675±104 | 114±8.58 | 0 | 243±36.0 | 40.9±1.64 | 145±10.3 | 1037±70.4 | 23.0±4.08 | 3.27±0.17 |

| DF – D | 81.4±1.81 | 2641±710 | 8332±883 | 3.66±0.06 | 843±216 | 121±12.7 | 0 | 298±0.24 | 43.8±12.1 | 160±16.8 | 1105±16.1 | 25.9±6.68 | 3.16±0.33 |

| PP – L | 77.9±20.0 | 821±257 | 3741±414 | 1.08±0.18 | 165±15.2 | 57.7±49.2 | 0.72±1.02 | 89.5±27.8 | 45.9±12.0 | 548±17.9 | 1260±323 | 20.0±3.88 | 11.2±0.55 |

| PP – W | 79.3±1.22 | 1547±97.4 | 6274±241 | 2.40±0.06 | 347±10.1 | 35.6±16.9 | 0 | 198±5.34 | 42.4±2.67 | 196±7.54 | 1186±42.0 | 17.4±0.51 | 1.51±0.72 |

| PP – D | 77.3±0.77 | 1909±195 | 7436±213 | 2.52±0.06 | 363±7.80 | 60.2±17.6 | 0 | 213±2.04 | 47.8±4.88 | 216±4.89 | 1162±24.6 | 16.9±0.46 | 2.37±0.71 |

| LPP – L | 74.9±13.29 | 1370±125 | 5656±1131 | 1.70±0.35 | 302±60.3 | 78.9±15.8 | 0 | 99.8±27.5 | 40.6±3.70 | 213±0.90 | 1005±0.99 | 18.19±1.68 | 4.02±0.24 |

| LPP – W | 82.4±2.64 | 2213±407 | 7283±948 | 3.40±0.20 | 536±46.7 | 103±25.6 | 0 | 230±7.85 | 30.6±6.62 | 152±22.0 | 1276±28.2 | 17.9±1.31 | 2.92±0.68 |

| LPP – D | 79.9±0.32 | 2494±325 | 9198±326 | 3.65±0.05 | 607±6.75 | 98.8±10.7 | 0 | 252±4.60 | 41.3±5.68 | 177±6.90 | 1067±49.2 | 18.8±0.14 | 2.58±0.29 |

| ML – L | – | – | – | – | – | – | – | – | – | – | – | – | – |

| ML – W | 79.8±7.01 | 1432±76.3 | 6385±754 | 2.52±0.30 | 398±49.6 | 117±17.5 | 24.0±18.8 | 169±53.8 | 38.3±2.04 | 197±2.11 | 1230±1.20 | 19.7±2.22 | 4.91±0.66 |

| ML – D | 83.2±0.12 | 1830±265 | 5590±269 | 2.76±0.18 | 443±16.9 | 78.7±18.9 | 0 | 191±56.8 | 45.70±6.61 | 161±7.76 | 1259±71.1 | 20.5±0.78 | 3.08±0.74 |

DF, Douglas-fir; LPP, lodgepole pine; PP, pitch pine; ML, mountain laurel; L, live; W, wet; D, dry. Please note that live pitch pine and mountain laurel leaves did not flame continuously, and the readings for live mountain laurel leaves were not recorded during smouldering

Flaming and smouldering combustion results in different emissions, most dramatically in CO and TPM production. Fig. 3 shows the influence of FMC on CO production during both flaming and smouldering combustion of Douglas-fir. As the FMC decreases, the CO concentration increases for smouldering combustion. This may be attributed to differences in the makeup of the moisture in the fuel, which could include volatiles that enhance combustion efficiency; however, such differences are not observed when time- and mass-averaged EFs are calculated (see next section). For flaming combustion, dry and live conditions produce the most CO emissions, with wet conditions generating significantly less CO. It is important to note that these results do not incorporate the influence of a reduced burning rate for wetter fuels and that the flame and heater move at different rates for flaming and smouldering combustion (see Table 1) which results in a shorter test duration for flaming versus smouldering. Smouldering tests with live fuels are an exception, where readings cannot be maintained for the full test duration due to changes between the high/low range of the Enerac sensor.

Fig. 3.

CO emissions for Douglas-fir with varying FMC under flaming (solid line) and smouldering (dashed line) conditions as measured directly out of the quartz tube.

Cumulative emissions

Fig. 4 shows the EF of various species at three different FMC. It was not possible to achieve a continuous flame for live pitch pine and mountain laurel leaves (50% FMC), suggesting some chemical differences between the remaining liquids or structural differences in the way compounds evaporate from leaves versus needles. This behaviour has been observed previously during convective ignition experiments (McAllister and Finney 2014), but it has not been reported in regards to sustained flaming or emission conditions. A similar behaviour was also observed by Engstrom et al. (2004) and Fletcher et al. (2007) while testing live fuel species using a flat-flame burner; however, resulting emissions were not a focus of either study.

Fig. 4.

(a–d) Average EFs of different species during flaming combustion of different fuels at three FMC conditions. (e) Average EFs of species during smouldering combustion of lodgepole pine at three FMC conditions. Error bars represent the standard deviation between averages from different tests.

For flaming combustion, between species, Douglas-fir and lodgepole pine show elevated EFs of TPM between 50% (live) and 10% (wet) FMC conditions, followed by a decrease from the 10% (wet) to the 2% (dry) conditions, whereas EFs of CO first decrease and then slowly increase. CO production is also notably higher for live conditions, which may be due to incomplete combustion, with the MCE dropping from 99% to 97% for this condition. Total production of CO and TPM was less for dry fuels compared with that for live and wet fuels, which is to be expected as the energy provided by the heater is spent in vaporising the moisture of live plants, thus delaying the complete combustion of the pyrolysis species. Pitch pine and mountain laurel, however, have opposite trends compared with Douglas-fir and lodgepole pine, which may have occurred due to differences in the chemical makeup of the fuels. NO and NO2 have been combined to NOx due to the negligible amount of NO2 detected. It is decreasing with decrease in FMC, except for mountain laurel.

Possell and Bell (2013) performed experiments on eucalyptus with varying FMC, and the peak CO released during mass-loss calorimetry followed a similar trend as our tests on conifers from Montana, Douglas-fir and lodgepole pine. Conifers from the New Jersey Pine Barrens, however, behave in a different manner, with pitch pine and mountain laurel showing little variation in emissions between wet and dry fuels.

Hydrocarbon emission factors were not presented for flaming conditions because they were negligible and within the sensitivity of the instrument (resolution of ±4 ppm). SO2 was also below 0.5 g kg−1 of fuel for all flaming conditions. McMeeking et al. (2009) previously observed SO2 EF in the range of 0–1 g kg−1 of fuel, so values reported here are in a similar range.

Unlike flaming, EFs from smouldering combustion are relatively uniform, regardless of FMC condition. EF of various species at three different FMC are reported for only lodgepole pine in Fig. 4e. EFs, MCE and average concentration for the fuel species under various FMC are reported in Table 2. Emissions of TPM, CO, HC and NOx are higher for smouldering compared with those for flaming. CO2 production during smouldering is lower than that for flaming by an order of magnitude, corresponding to a reduction in HRR. Further, statistical analysis supported the observed differences between flaming and smouldering combustion. A paired sample t-test was performed on the average values of the EFs, and the value of P was obtained as 1.05e–9, 4.25e–9 and 1.87e–4 for TPM, CO and CO2 respectively, signifying greater variation of emission species among two different combustion conditions. SO2 is not reported due to negligible levels detected.

A small decrease in TPM and CO EFs is observed for the wet condition in smouldering Douglas-fir and lodgepole pine fuels, similarly seen in MCE. Pitch pine also has the lowest CO EF for wet fuel, but the CO EF for live fuel is almost three times that of the wet and dry conditions. The NOx EF follows the same trend as CO for pitch pine, whereas it is relatively uniform for other fuel types. An increased mass of fuel was used for lodgepole pine compared with that for pitch pine, yet the TPM EF is comparatively lower than that for pitch pine. With small decreases in the TPM and CO EFs for the wet condition, there is a small increase in the CO2 EF. The opposite trend of the CO and CO2 EFs can be explained by the oxygen supply and carbon content present in the controlled emissions setup. Smouldering of the type of vegetation chosen in this study has previously been discussed in the literature, but Hu et al. (2019a, 2019b) is the only one to have explored the effect of FMC, and for that study only on smouldering peat fires. It is interesting to note that the CO EF for previous studies of peat fires did not vary much with FMC, similar to what was observed in this study for Douglas-fir, lodgepole pine and mountain laurel. The average HC EF for different fuels is around 20 g kg−1, and this value is comparable to those reported by McMeeking et al. (2009).

Discussion

A major requirement of the new apparatus built in this study was to produce steady emissions from vegetative fuels under different burning conditions. The time-dependent emissions behaviour of wet Douglas-fir (Fig. 2) showed the resulting adaptability of the apparatus as the emissions produced are relatively constant throughout the test duration and a similar trend was found for all other fuel types under both flaming and smouldering combustion conditions. Control over the amount of fuel, ambient airflow, heater temperature and moving rate makes this setup versatile allowing for emissions to be measured from a vast array of fuels varying in FMC, size (long versus short pine needles) and shape (needles versus leaves) under different combustion conditions (flaming, smouldering, pyrolysis (in an inert atmosphere) and even mixed modes of combustion).

Emissions were found to vary between both species and the FMC of the vegetation. The MCE, which roughly characterises a transition between flaming and smouldering, was determined to be ~99% ± 0.8% for flaming experiments and ~80% ± 2.5% for smouldering experiments. Field observations from wildland fires have reported a MCE between 85% and 95%, as there is a mix of both flaming and smouldering (Urbanski 2013, 2014). As expected, HRR increases with decreasing FMC for both smouldering and flaming. Our apparatus, in essence, achieves extreme conditions, that is, fully flaming and fully smouldering, which is helpful to better understand and characterise the source of these emissions. Unlike most previous experiments, fuels were dried at low temperatures to preserve liquid volatiles, rather than completely drying them at first and then rehydrating them to introduce FMC (Chen et al. 2010; Smith et al. 2013). The presence of this liquid both inhibits combustion by requiring additional energy for vaporisation and, in some cases, may contribute to heat release through remaining liquid volatiles.

Both CO and HC EFs for smouldering combustion remain relatively constant for all fuels, whereas for flaming combustion variations are observed for CO as a function of both fuel type and FMC. The CO concentration decreases with increased FMC for smouldering combustion, but for flaming it shows a small reduction and then increases with increase in the FMC (see Fig. 3). This is similar to what Hu et al. (2019a) observed for experiments over smouldering peat fires and Possell and Bell (2013) for flaming eucalyptus experiments. TPM measurements generally followed similar trends. These trends no longer appear for smouldering combustion when considering fuel consumption in the EF (see Fig. 4e, similar to Hu et al. 2019a, 2019b). Gravimetric filter samples also appeared starkly different after tests with flaming versus smouldering samples as shown in Fig. 5. Flaming experiments resulted in what appeared to be black carbon particles, whereas smouldering experiments had a yellowish colour, indicating the presence of aerosols that should be chemically analysed in the future. McMahon et al. (1980) and Hu et al. (2019a, 2019b) have also reported the similar difference between filters but did not analyse them chemically. Differences in the colour of filters was also observed among the fuel species. As shown in Fig. 5a, b, Douglas-fir, pitch pine and lodgepole pine produce much darker particles than mountain laurel under flaming experiments, and all four fuel types resulted in yellow colour filters under smouldering combustion.

Fig. 5.

Particles emitted from (a) flaming DF, LPP and PP, (b) flaming ML and (c) smouldering combustion conditions.

Video observations also reveal further differences between fuel types. Douglas-fir exhibits a ‘popping’ behaviour during flaming combustion that is not observed with other fuels. This behaviour was previously noted by McAllister and Finney (2014), who observed ‘bursting’ of vapours from recently-live pine needles under convective heating. Engstrom et al. (2004) and Fletcher et al. (2007) also reported bubbling/bursting of leaf surfaces that contain a high moisture content. This highlights the effect not only of volatiles that could be present in the fuel, but also of structural differences that change the manner in which the volatiles are released. These differences may together contribute to the variability in EFs across species. For flaming combustion, the EF of CO for both mountain laurel and pitch pine is about half that of Douglas-fir and lodgepole pine under wet conditions and ~1/3 of that for NOx. The fact that pitch pine and mountain laurel could not sustain flaming combustion under a nearly-live (~50% FMC) condition further highlights these differences.

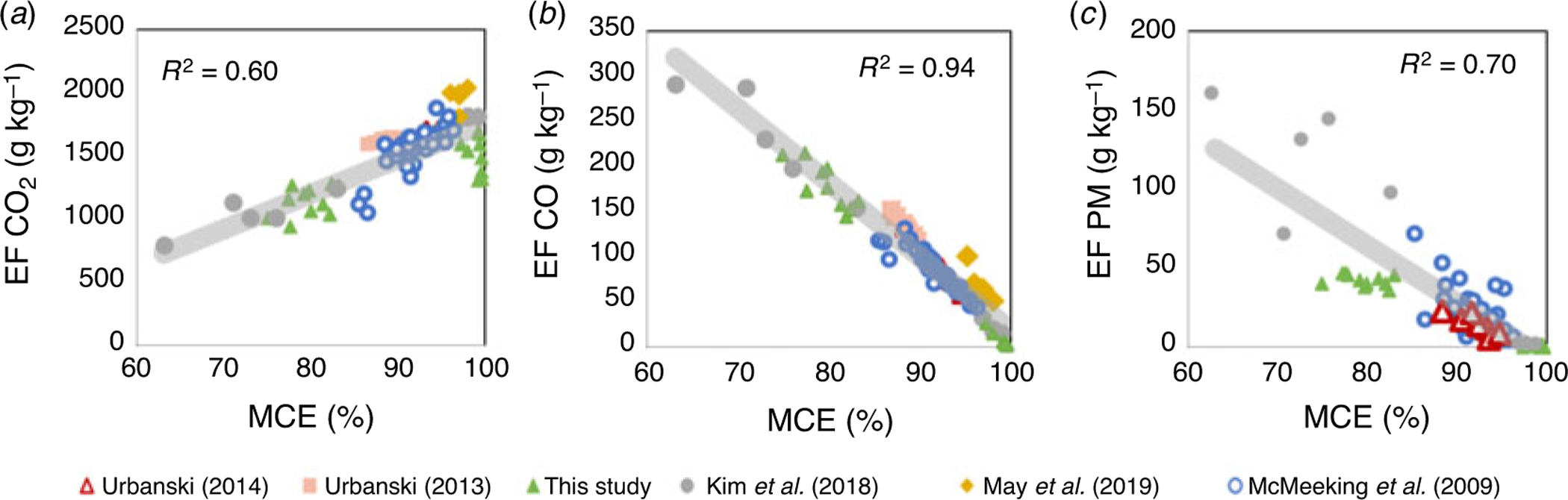

It is known in the field of fire toxicity that scale will affect emissions and not all the results can be replicated at the small scale. Previous studies have found strong correlations between calculated EFs and MCE. To validate the results obtained using this tube-heater apparatus, EFs for CO, CO2 and PM were compared with published EFs from previous biomass combustion studies. Here we compare our results with five different studies in the literature, out of which two were prescribed fires (Urbanski 2013, 2014), two were open combustion experiments in a laboratory (McMeeking et al. 2009; May et al. 2019), and one study was performed in a similar apparatus but run in an opposite, concurrent configuration (Kim et al. 2018). Among these studies, only May et al. (2019) have explicitly varied FMC. Fig. 6 shows how the EFs are linearly dependent on MCE. These linear trends are fitted with a linear function with R2 values of 0.60, 0.94 and 0.70 for CO2, CO and PM respectively. CO has the strongest correlation with MCE. It is interesting to note that field studies generally lie between fully smouldering and flaming conditions, as achieved in this and one previous study (Kim et al. 2018), indicating that real fires typically incorporate mixed modes of combustion that cannot always be well documented in the field but can be very well studied in the small-scale setup developed in this study.

Fig. 6.

A comparison of EFs of different species during flaming and smouldering combustion versus MCE. Results from previous studies are also shown (McMeeking et al. 2009; Urbanski 2013, 2014; Kim et al. 2018; May et al. 2019).

Conclusions

It is clear that the new apparatus built to steadily generate emissions from vegetative fuels highlighted the strong effect of FMC on emissions from fires in many cases. Decreased FMC often results in higher heat release during combustion and lower heating rates needed to achieve sustained flaming combustion. As expected, smouldering combustion resulted in significantly increased CO, PM and HC emissions compared with flaming for all the fuel types. For flaming combustion, CO production decreases from live to wet and slightly increases from wet to dry for Douglas-fir and lodgepole pine, but little variation is observed with FMC between pitch pine and mountain laurel. Higher FMC, therefore, does not always result in different emissions; it depends on the nature of the fuel. For smouldering combustion, emissions are similar between wet and dry fuels, in contrast to what was observed in previous peat studies.

FMC effects on emissions have not been well documented in the past, due in part to difficulties acquiring and testing large quantities of fuels. This new approach, with small fuel samples under controlled environments, provides a platform from which to deduce effects of fuel species, FMC and burning conditions on produced effluents. Although differences between laboratory-scale tests and field conditions will always occur, trends observed in the laboratory can be useful to highlight variations that are observable in the field, including those relevant to human health. Open questions remain, such as capturing a broader spectrum of effluents, understanding the chemical composition of different vegetation, investigating the filter colour difference from flaming and smouldering combustion, increasing the number of different FMC conditions, and assessing the variation in emissions between experiments at different scales.

Acknowledgements

The authors would like to thank Dhia Putri, Ben Biallas, Anita Stoppel and Julia Duarte for their assistance with laboratory experiments and Michael Gallagher and Chelsea Phillips from the USDA Forest Service for acquiring fuels.

Declaration of funding

This work was supported by the US Department of Homeland Security (DHS)/Federal Emergency Management Agency (FEMA) Fire Prevention and Safety Grant program award EMW-2017-FP-00446.

Footnotes

Conflicts of interest

The authors declare no conflicts of interest.

Hu et al. (2019a, 2019b) and others define FMC as the mass of water in the sample divided by the dry mass of the sample, resulting in a FMC as high as 160%.

References

- Adetona O, Reinhardt TE, Domitrovich J, Broyles G, Adetona AM, Kleinman MT, Ottmar RD, Naeher LP (2016) Review of the health effects of wildland fire smoke on wildland firefighters and the public. Inhalation Toxicology 28, 95–139. doi: 10.3109/08958378.2016.1145771 [DOI] [PubMed] [Google Scholar]

- Burling IR, Yokelson RJ, Griffith DWT, Johnson TJ, Veres P, Roberts JM, Warneke C, Urbanski SP, Reardon J, Weise DR, Hao WM, De Gouw J (2010) Laboratory measurements of trace gas emissions from biomass burning of fuel types from the southeastern and southwestern United States. Atmospheric Chemistry and Physics 10, 11115–11130. doi: 10.5194/ACP-10-11115-2010 [DOI] [Google Scholar]

- Butler BM, Palarea-Albaladejo J, Shepherd KD, Nyambura KM, Towett EK, Sila AM, Hillier S (2020) Mineral–nutrient relationships in African soils assessed using cluster analysis of X-ray powder diffraction patterns and compositional methods. Geoderma 375, 114474. doi: 10.1016/J.GEODERMA.2020.114474 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Chen LWA, Verburg P, Shackelford A, Zhu D, Susfalk R, Chow JC, Watson JG (2010) Moisture effects on carbon and nitrogen emission from burning of wildland biomass. Atmospheric Chemistry and Physics 10, 6617–6625. doi: 10.5194/ACP-10-6617-2010 [DOI] [Google Scholar]

- Einbrodt HJ, Hupfeld J, Prager FH, Sand H (1984) The suitability of the DIN 53436 test apparatus for the simulation of a fire risk situation with flaming combustion. Journal of Fire Sciences 2, 427–438. doi: 10.1177/073490418400200603 [DOI] [Google Scholar]

- Engstrom JD, Butler JK, Smith SG, Baxter LL, Fletcher TH, Weise DR (2004) Ignition behavior of live California chaparral leaves. Combustion Science and Technology 176, 1577–1591. doi: 10.1080/00102200490474278 [DOI] [Google Scholar]

- Fletcher TH, Pickett BM, Smith SG, Spittle GS, Woodhouse MM, Haake E, Weise DR (2007) Effects of moisture on ignition behavior of moist California Chaparral and Utah leaves. Combustion Science and Technology 179, 1183–1203. doi: 10.1080/00102200601015574 [DOI] [Google Scholar]

- Freeborn PH, Wooster MJ, Hao WM, Ryan CA, Nordgren BL, Baker SP, Ichoku C (2008) Relationships between energy release, fuel mass loss, and trace gas an aerosol emissions during laboratory biomass fires. Journal of Geophysical Research, D, Atmospheres 113, D01301. doi: 10.1029/2007JD008679 [DOI] [Google Scholar]

- Hayashi K, Ono K, Kajiura M, Sudo S, Yonemura S, Fushimi A, Saitoh K, Fujitani Y, Tanabe K (2014) Trace gas and particle emissions from open burning of three cereal crop residues: Increase in residue moistness enhances emissions of carbon monoxide, methane, and particulate organic carbon. Atmospheric Environment 95, 36–44. doi: 10.1016/J.ATMOSENV.2014.06.023 [DOI] [Google Scholar]

- Hu Y, Christensen EG, Amin HMF, Smith TEL, Rein G (2019a) Experimental study of moisture content effects on the transient gas and particle emissions from peat fires. Combustion and Flame 209, 408–417. doi: 10.1016/J.COMBUSTFLAME.2019.07.046 [DOI] [Google Scholar]

- Hu Y, Christensen E, Restuccia F, Rein G (2019b) Transient gas and particle emissions from smouldering combustion of peat. Proceedings of the Combustion Institute 37, 4035–4042. doi: 10.1016/J.PROCI.2018.06.008 [DOI] [Google Scholar]

- Janssens M (2016) Calorimetry. In ‘SFPE handbook of fire protection engineering, fifth edition’. (Eds Hurley MJ, Gottuk D, Hall JR Jr, Harada K, Kuligowski E, Puchovsky M, Torero J, Watts JM Jr, Wieczorek C) pp. 905–951. (Springer: New York, NY: ) [Google Scholar]

- Jervis F, Rein G (2016) Experimental study on the burning behaviour of Pinus halepensis needles using small-scale fire calorimetry of live, aged and dead samples. Fire and Materials 40, 385–395. doi: 10.1002/FAM.2293 [DOI] [Google Scholar]

- Kim YH, Warren SH, Krantz QT, King C, Jaskot R, Preston WT, George BJ, Hays MD, Landis MS, Higuchi M, Demarini DM, Gilmour MI (2018) Mutagenicity and lung toxicity of smoldering vs. Flaming emissions from various biomass fuels: Implications for health effects from wildland fires. Environmental Health Perspectives 126, 017011. doi: 10.1289/EHP2200 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Matt FJ, Dietenberger MA, Weise DR (2020) Summative and Ultimate Analysis of Live Leaves from Southern U.S. Forest Plants for Use in Fire Modeling. Energy & Fuels 34, 4703–4720. doi: 10.1021/ACS.ENERGYFUELS.9B04107 [DOI] [Google Scholar]

- May N, Ellicott E, Gollner M (2019) An examination of fuel moisture, energy release and emissions during laboratory burning of live wildland fuels. International Journal of Wildland Fire 28, 187–197. doi: 10.1071/WF18084 [DOI] [Google Scholar]

- McAllister S, Finney M (2014) Convection ignition of live forest fuels. Fire Safety Science 11, 1312–1325. doi: 10.3801/IAFSS.FSS.11-1312 [DOI] [Google Scholar]

- McMahon CK, Wade DD, Tsoukalas SN (1980) Combustion characteristics and emissions from burning organic soils. In ‘73rd Annual Meeting of the Air Pollution Control Association’, 22–27 June 1980, Montreal, Quebec, pp. 2–16. [Google Scholar]

- McMeeking GR, Kreidenweis SM, Baker S, Carrico CM, Chow JC, Collett JL, Hao WM, Holden AS, Kirchstetter TW, Malm WC, Moosmüller H, Sullivan AP, Cyle EW (2009) Emissions of trace gases and aerosols during the open combustion of biomass in the laboratory. Journal of Geophysical Research, D, Atmospheres 114, D19210. doi: 10.1029/2009JD011836 [DOI] [Google Scholar]

- Mobley HE, Barden CR, Crow AB, Fender DE, Jay DM, Winkworth RC (1976) Southern Forestry Smoke Management Guidebook. USDA Forest Service, Southeastern Forest Experiment Station, General Technical Report SE-10, pp. 1–140. (Asheville, NC, USA: ) [Google Scholar]

- Possell M, Bell TL (2013) The influence of fuel moisture content on the combustion of Eucalyptus foliage. International Journal of Wildland Fire 22, 343–352. doi: 10.1071/WF12077 [DOI] [Google Scholar]

- Prager FH (1988) Assessment of Fire Model DIN 53436. Journal of Fire Sciences 6, 3–24. doi: 10.1177/073490418800600101 [DOI] [Google Scholar]

- Rahimmalek M, Goli SAH (2013) Evaluation of six drying treatments with respect to essential oil yield, composition and color characteristics of Thymys daenensis subsp. daenensis. Celak leaves. Industrial Crops and Products 42, 613–619. doi: 10.1016/J.INDCROP.2012.06.012 [DOI] [Google Scholar]

- Rappold AG, Stone SL, Cascio WE, Neas LM, Kilaru VJ, Carraway MS, Szykman JJ, Ising A, Cleve WE, Meredith JT, Vaughan-Batten H, Deyneka L, Devlin RB (2011) Peat bog wildfire smoke exposure in rural North Carolina is associated with cardiopulmonary emergency department visits assessed through syndromic surveillance. Environmental Health Perspectives 119, 1415–1420. doi: 10.1289/EHP.1003206 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Reid CE, Brauer M, Johnston FH, Jerrett M, Balmes JR, Elliott CT (2016) Critical review of health impacts of wildfire smoke exposure. Environmental Health Perspectives 124, 1334–1343. doi: 10.1289/EHP.1409277 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Reinhardt TE, Ottmar RD (2000) Smoke exposure at western wildfires. USDA Forest Service, Pacific Northwest Research Station, Research Paper PNW-RP-525, pp. 1–72. (Portland, OR, USA: ). doi: 10.2737/PNW-RP-525 [DOI] [Google Scholar]

- Reinhardt TE, Ottmar RD (2004) Baseline measurements of smoke exposure among wildland firefighters. Journal of Occupational and Environmental Hygiene 1, 593–606. doi: 10.1080/15459620490490101 [DOI] [PubMed] [Google Scholar]

- Reisen F, Hansen D, Meyer CP (2011) Exposure to bushfire smoke during prescribed burns and wildfires: Firefighters’ exposure risks and options. Environment International 37, 314–321. doi: 10.1016/J.ENVINT.2010.09.005 [DOI] [PubMed] [Google Scholar]

- Seiler W, Crutzen PJ (1980) Estimates of Gross and Net Fluxes of Carbon Between. Climatic Change 2, 207–247. doi: 10.1007/BF00137988 [DOI] [Google Scholar]

- Smith AMS, Tinkham WT, Roy DP, Boschetti L, Kremens RL, Kumar SS, Sparks AM, Falkowski MJ (2013) Quantification of fuel moisture effects on biomass consumed derived from fire radiative energy retrievals. Geophysical Research Letters 40, 6298–6302. doi: 10.1002/2013GL058232 [DOI] [Google Scholar]

- Stec AA, Hull TR, Lebek K (2008) Characterisation of the steady state tube furnace (ISO TS 19700) for fire toxicity assessment. Polymer Degradation & Stability 93, 2058–2065. doi: 10.1016/J.POLYMDEGRADSTAB.2008.02.020 [DOI] [Google Scholar]

- Unosson J, Blomberg A, Sandström T, Muala A, Boman C, Nyström R, Westerholm R, Mills NL, Newby DE, Langrish JP, Bosson JA (2013) Exposure to wood smoke increases arterial stiffness and decreases heart rate variability in humans. Particle and Fibre Toxicology 10, 20. doi: 10.1186/1743-8977-10-20 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Urbanski SP (2013) Combustion efficiency and emission factors for wildfire-season fires in mixed conifer forests of the northern Rocky Mountains, US. Atmospheric Chemistry and Physics 13, 7241–7262. doi: 10.5194/ACP-13-7241-2013 [DOI] [Google Scholar]

- Urbanski S (2014) Wildland fire emissions, carbon, and climate: Emission factors. Forest Ecology and Management 317, 51–60. doi: 10.1016/J.FORECO.2013.05.045 [DOI] [Google Scholar]

- Ward E (1983) Particulate Matter Emissions for Fires in the Palmetto-Gallberry Fuel Type. Forest Science 29, 761–770. [Google Scholar]

- Ward DE, Hao WM (1991) Projections of emissions from burning of biomass for use in studies of global climate and atmospheric chemistry. In ‘84th Annual Meeting & Exhibition’, 16–21 June 1991, Vancouver, British Columbia. Air and Waste Management Association, pp. 1–16. [Google Scholar]

- Ward DE, Hardy CC (1991) Smoke emissions from wildland fires. Environment International 17, 117–134. doi: 10.1016/0160-4120(91)90095-8 [DOI] [Google Scholar]

- Weise DR, Jung H, Palarea-Albaladejo J, Cocker DR (2020a) Compositional data analysis of smoke emissions from debris piles with low-density polyethylene. Journal of the Air & Waste Management Association 70, 834–845. doi: 10.1080/10962247.2020.1784309 [DOI] [PubMed] [Google Scholar]

- Weise DR, Palarea-Albaladejo J, Johnson TJ, Jung H (2020b) Analyzing Wildland Fire Smoke Emissions Data Using Compositional Data Techniques. Journal of Geophysical Research, D, Atmospheres 125, e2019JD032128. doi: 10.1029/2019JD032128 [DOI] [Google Scholar]