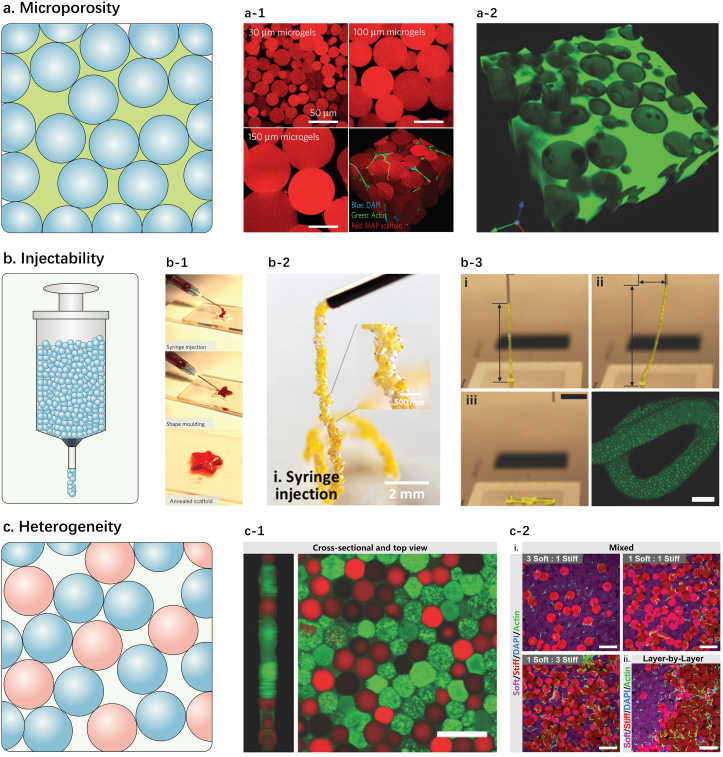

Fig. 3.

Characteristics of microgel assembly: (a) microporosity. a-1: images from Ref. [19] show the porous structures inside microgel assembly using different sizes of PEG microgels (scale bar: 50 μm); a-2: image from Ref. [39] shows a 3D PEG microgel assembly filled with a fluorescently labeled high-molecular-weight dextran solution, demonstrating the interconnectivity of pores within the construct (scale bar: N/A); (b) injectability. b-1: images from Ref. [19] show the formation process of pentagram by needle-injection of PEG microgel assembly (scale bar: N/A); b-2: image from Ref. [9] shows injection of GelMA/chitosan methacrylate microgel assembly from a 26 G needle (scale bar: 2 mm); b-3: images from Ref. [32] show the extrudability of HA microgels on a 3D printer (scale bar: 5 mm); (c) heterogeneity. c-1: images from Ref. [47] show confocal images (cross-sectional and top views) of two-component HA microgel assembly containing cleavable microgels with encapsulated FITC-BSA (green) and stable microgels containing RHO-DEX (red) (scale bar: 100 μm); c-2: images from Ref. [28] show mechanically heterogeneous scaffolds formed by two kinds of cell-laden microgels in situ through various schemes and different ratios of microgel components (scale bar: 200 μm). Reprinted with the permission from Springer Nature, John Wiley and Sons. (For interpretation of the references to color in this figure legend, the reader is referred to the Web version of this article.)