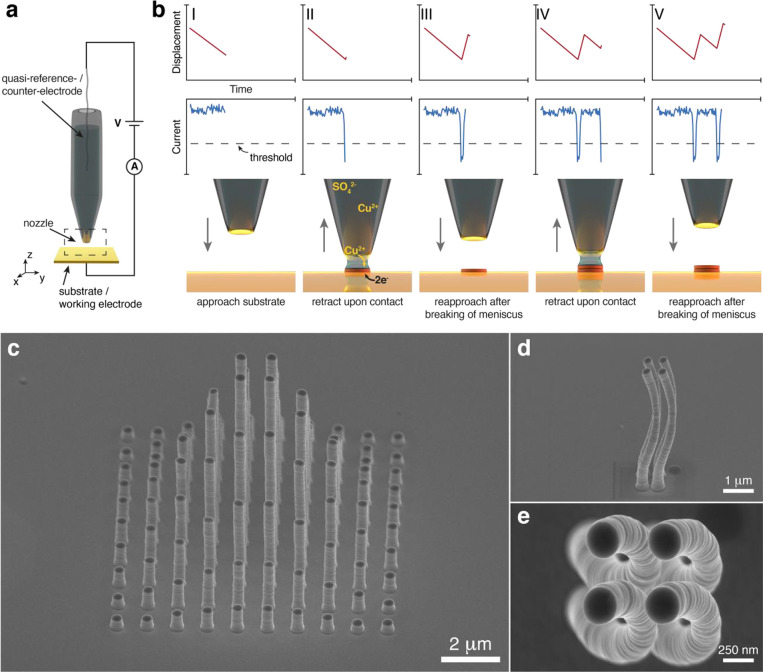

Figure 1.

(a) Schematic of the printing setup. The nozzle, containing the electrolyte solution and the quasi-reference counter electrode, is placed above a conductive substrate that constitutes the working electrode of the two-electrode electrochemical cell. The substrate and the nozzle are translated with respect to each other by piezoelectric nanopositioners. (b) Schematic of the printing process of a voxel. A negative voltage is applied between the substrate and the quasi-reference/counter-electrode. (I,II) The pipette approaches the substrate until the current drops below a preset threshold value due to the formation of a liquid meniscus. The copper cations in the electrolyte are reduced to copper on the substrate. (III) To prevent copper growth into the nozzle, the pipette is retracted immediately after the faradaic current reaches the threshold until the meniscus is broken and hence electrodeposition is halted. (IV,V) This procedure is repeated until a certain voxel height is reached. The gray arrows next to the nozzle indicate the direction of the vertical movement of the nozzle. The current and distance graphs in the top row depict the vertical piezo displacement (upper, red) and the evolution of the electrical current (lower, blue) during the printing process. (c–e) Electron microscope images of 3D printed structures with a 253 nm nozzle. (c) Sideview of a 10 × 10 array of pillars (656 voxels) forming a Gaussian peak with increasing heights toward the center of the array. Side (d) and top (e) view on four helical structures printed with a center-to center spacing of 500 nm.