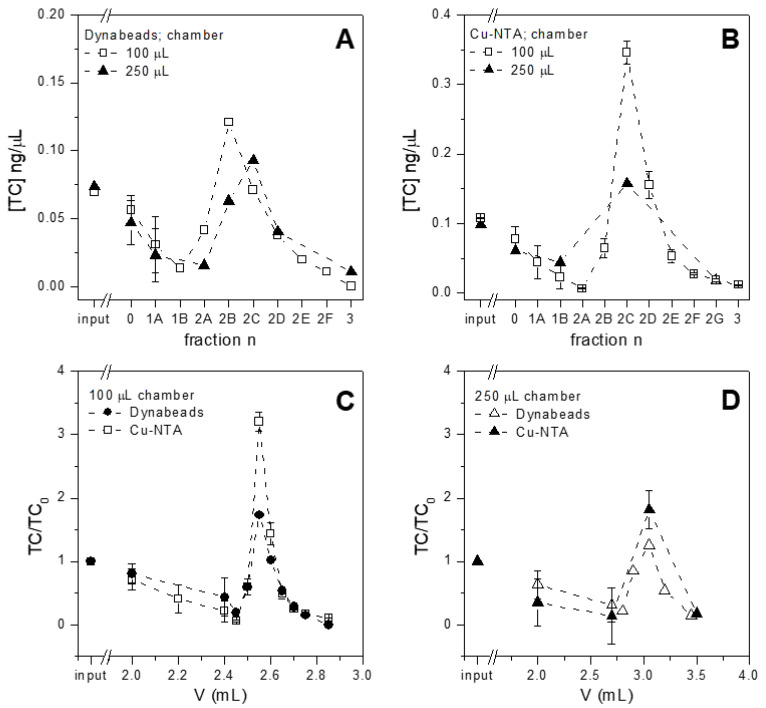

Figure 5.

Purification of tetracycline spiked in buffer with microfluidic chips carrying chambers of different volumes and loaded with the two types of beads. Panel (A): Dynabeads tested in different chambers; panel (B): Cu-NTA beads in different chambers. The x axis shows the fractions collected at the outlet of the system, and in particular, fraction 0 represents the tetracycline collected during injection (unbound), fractions 1A–1B represent the volume collected during washes, while fractions 2A–2G represent the volume collected during the elution step and finally, fraction 3 represents a final wash; Panels (C,D): the tetracycline concentration found in different fractions was normalized to the concentration of injected tetracycline (TC/TC) in same volume chambers (100 µL in panel (C) and 250 µL in panel (D)) loaded with the two types of beads. The x axis shows the volume fluxed in the microfluidic chambers.