Abstract

As a promising alternative to the market-leading lithium-ion batteries, low-cost sodium-ion batteries (SIBs) are attractive for applications such as large-scale electrical energy storage systems. The energy density, cycling life, and rate performance of SIBs are fundamentally dependent on dynamic physiochemical reactions, structural change, and morphological evolution. Therefore, it is essential to holistically understand SIBs reaction processes, degradation mechanisms, and thermal/mechanical behaviors in complex working environments. The recent developments of advanced in situ and operando characterization enable the establishment of the structure–processing–property–performance relationship in SIBs under operating conditions. This Review summarizes significant recent progress in SIBs exploiting in situ and operando techniques based on X-ray and electron analyses at different time and length scales. Through the combination of spectroscopy, imaging, and diffraction, local and global changes in SIBs can be elucidated for improving materials design. The fundamental principles and state-of-the-art capabilities of different techniques are presented, followed by elaborative discussions of major challenges and perspectives.

Lithium-ion batteries (LIBs) are dominant energy storage solutions in portable electronics and electrified transportation. However, risks related to the supply chain of key elements of LIBs have intensified the search for more sustainable alternatives toward decarbonization. Sodium-ion batteries (SIBs) have been considered as an appealing candidate owing to the low cost of raw materials, high natural abundance, and environmental benignity compared to LIBs. Historically, research on LIBs and SIBs began around the same time in the 1970s and early 1980s.1−4 Since the commercialization of LIBs by Sony in 1991, research and development in LIBs skyrocketed; meanwhile, progress on SIBs slowed down because of their inferior energy density and capacity retention compared to LIBs. In the past decade, we witnessed the renaissance of SIBs with improved electrochemical performance and retained economic advantages. Despite advancements of many other beyond-Li technologies, including K-ion batteries, Mg-ion batteries, etc., SIBs best satisfy performance, cost, and scaling targets, approaching a commercialization stage recently. The revival of SIBs is also catalyzed by demands for reliable and cost-effective grid-scale energy storage systems for intermittent renewable energy sources (e.g., wind and solar).

The advantages and disadvantages of SIBs are often highlighted in open literature.5−7 Concerning the former, first, it is acknowledged that the raw materials, e.g., sodium salts, are more abundant in the Earth’s crust and more widely distributed geographically than LIBs counterparts.7 SIB cathodes may rely less on scarce minerals containing Ni and Co. Second, sodium is free of alloy reaction with aluminum at room temperature, allowing for the use of cheaper and lighter aluminum rather than copper as the current collector for anodes to further reduce cost.8 Third, the safety issue of SIBs is less severe: the thermal runaway during the electrode and electrolyte decomposition is much less than for the LIB counterparts.9 Fourth, although Na+ has a larger size than Li+, sodium ion transport is faster in electrolytes because it is less polarizing and has smaller solvation energy.10 The lower desolvation energy penalty is conducive to the capacity retention at low temperature. Additionally, because of the similar working principles and cell configurations, the manufacturing infrastructure of LIBs can be readily adapted to SIBs. Last but not least, Na metal is softer than Li, and formation of dendrites may be restrained by mechanical pressure or by employing appropriate separators with higher shear modulus.11 Considerating the aforementioned merits depicted in Figure 1, SIBs can be complementary to LIBs, catering to grid storage, industrial/household power, low-speed electric cars, etc.

Figure 1.

Schematic of major advantages of SIBs. “EC” in the bottom-left panel represents ethylene carbonate (indispensible solvent in LIBs) that hampers low-temperature performances. The figure in the top-right panel is reprinted with permission from ref (9). Copyright 2016 Elsevier.

Regarding the disadvantages, the standard electrode potential of Na (−2.70 V) is higher than that of Li (−3.04 V) with respect to the standard hydrogen electrode (SHE). In addition, Na is heavier than Li. Hence, generally speaking, the theoretical specific energy of a SIB is lower than its LIB counterpart.12,13 Nevertheless, it has been shown that the difference in theoretical energy of LIBs and SIBs with similar electrode materials (Li: C∥Li0.5Li0.5CoO2; Na: C∥Na0.5Li0.5CoO2) is only ∼10%, excluding the consideration of the weight of other battery components such as electrolyte, current collector, additives, and packaging.14,15

Over the past decade, enormous efforts have been devoted to the design of new active materials as well as improvement of existing ones for SIBs. However, the majority of the candidates to date cannot meet the stringent performance requirements for practical applications, urging fundamental understandings toward pertinent battery degradation mechanisms.

In principle, the analysis of a battery can be categorized on different spatial scales from atomic scale, primary particle scale, secondary particle scale, and electrode scale, as illustrated in Figure 2. Global information includes the phase evolution, valence change, and coordination of cations and anions, representing the averaged behaviors from all particles. Local information includes disorder, defects, orientation, and heterogeneity, representing individual behaviors within and between particles.16 Various processes occurring at the meso-scale involve charge distribution, phase propagation, microstructure evolution, transition metal (TM) migration, and changes in geometric/mechanical properties.17,18 It should be mentioned that multi-scale charge heterogeneity is universal, tremendously affecting material degradation, cycling performances, and safety. This phenomenon is modulated by reaction mechanism/grain orientation at the particle level and tortuosity/porosity at the electrode level. At the nanoscale, atomic arrangement, surface reconstruction, and solid–electrolytes interphase (SEI) formation/growth are key points of information. During cycling, all of these physical, chemical, and structural properties can potentially undergo changes.

Figure 2.

Scheme of a battery at different scales and underlying scientific information correlated with electrochemical properties. The image at atomic scale is from Wikipedia, while the image at the macroscopic scale is adapted from ref (19), copyright 2020 Springer Nature.

A battery can be either an open or a closed system, which is a collection of dynamic bulks as well as interfaces. Most commonly, active materials are analyzed using different ex situ characterization methods at specific states of charge (SOCs) and cycles. Ex situ characterizations require disassembling batteries and post-treatments of battery materials, leading to potential contamination of the samples. If the tested materials are sensitive to air/moisture, they need additional protection. More importantly, during the storage and transfer, the real chemical and structural information might have altered. Ex situ analysis can be preliminary steps, but only the equilibrium state is probed. Therefore, to gain sufficient understanding of aforementioned dynamic changes, it is essential to apply higher-level in situ or real-time (operando) characterizations.

The advances of various in situ/operando characterization tools in LIBs serve as a cornerstone for the development of SIB characterizations. There has been phenomenal progress toward developing in situ/operando electron- and X-ray-based methods in LIBs, which have been summarized in many reviews.20−24 These developments paved the way for various in situ and operando investigations in SIBs, including transmission electron microscopy (TEM), X-ray diffraction (XRD), X-ray absorption spectroscopy (XAS), X-ray imaging and tomography, and pair distribution function (PDF). Nevertheless, compared to LIBs, SIBs offer ample opportunities to broaden the horizon to investigate dynamic processes such as those associated with ion–ion or ion–lattice interactions, defect evolution, and interfacial chemistry. It should be noted that properties and processes such as thermodynamic/kinetic properties and phase transitions can be distinctly different for SIBs and LIBs for similar compounds. For example, electrochemical cycling of olivine NaFePO4 is accompanied by different reaction mechanisms and partial amorphization as compared to the LiFePO4 counterpart.25 The reaction intermediates of electrodes cycled in SIBs (e.g., TiO2, Sn) are often found to be metastable or amorphous, making them challenging to probe using post mortem analysis. Many of the reaction pathways in electrodes used in SIBs remain elusive. Hence, it is critical to focus on the in situ/operando investigations that elucidate charge storage and transport mechanisms, phase transitions, crystalline-to-amorphous transformations, and morphological and mechanical responses of electrodes in SIBs during operation. Besides the hardware and protocol compatibility, the remarkable advantage of in situ/operando characterization of Na-based system lies in the imaging: Li in LIBs is of low Z number (3), which makes the direct measurement of spatial Li propagation under operation almost impossible. In SIBs, the increased Z (11) of Na enables the direct observation of the Na+ migration pathway and distribution at the primary particle level.26 These fundamental understandings will not only inspire future design of battery materials for SIBs but also provide valuable insights into the development of other battery systems.

In this Review, recent advances in in situ and operando characterizations for SIBs studies are summarized. The focus will be on how state-of-the-art analytical techniques facilitate the elucidation of the reaction mechanisms and degradation mechanisms in SIBs under operation. Pertinent establishment of structure–property–processing–performance relationship is based on distinct diagnosis methods that can unravel materials chemistry information, including global/local crystal structure, overall/heterogeneous electronic states, the evolution of morphology, dissolution or redistribution, thermal and mechanical dynamics of electrode materials, etc. We present research case studies organized by the class of different reaction mechanisms and discuss how complementary probing tools can be integrated. In addition, we outline the pitfalls, limitations, and perspectives for each characterization.

1. In Situ TEM

TEM has been widely applied in diagnosis of battery systems. A wide range of secondary signals are produced when the incident electrons interact with a thin specimen.27 These signals are categorized according to their corresponding analytical information: (1) imaging modes in real space, (2) diffraction modes in reciprocal space, (3) spectroscopy mode in energy space, and (4) in temporal domains. As a result, TEM benefits from the strong interactions between electrons and materials to provide localized structural and chemical information. A typical TEM has a resolving power of ∼0.2 nm, establishing a direct communication between the lattice image and the projected crystal structure. More recently, the development of aberration-corrected (cs-corrected) TEM and cryo-TEM instrumentation has achieved higher resolution down to 0.5 Å and lower dose environment, which is particularly suitable for studies of radiation-sensitive materials. The pnCCD TEM camera employs a direct monitor which has a minimum readout speed of 1000 full frames per second with a size of 264 × 264 pixels, providing the ability to capture transient structural changes.28In situ TEM analysis at the atomic scale and nanoscale is an ideal tool for understanding reactions and phase transitions of battery materials during synthesis or insertion/extraction of Na+ during electrochemical cycling–morphological evolution (especially volume changes of electrode materials along with Na+ insertion/extraction), phase transformations upon charging/discharging processes, degradation mechanisms of active materials during cycling, SEI formation, and thermal stability and mechanical behaviors of electrodes.29,30

Primary performance metrics of SIBs include capacity, cycle life, rate capability, and safety. The electrochemical reactions of electrode materials are generally categorized into three types according to the Na+ storage mechanism: intercalation reaction, alloying reaction, and conversion reaction. In order to elucidate the underlying mechanisms of these reactions, comprehensive in situ TEM studies have been conducted. Various in situ TEM designs have been successfully applied for the LIB studies.31,32 Considering the high vacuum operation condition in the TEM, two types of configurations are commonly used for in situ TEM investigation: open-cell and sealed liquid-cell configurations (Figure 3). In the case of an open-cell platform (Figure 3a), working electrode directly contacts with non-volatile electrolytes (Li2O or ionic liquid) to form a micro-cell system. Here, Li2O is a product from surface oxidation of Li metal when a TEM holder is inserted into the column. Due to the direct irradiation of the electron beam onto samples, the open-cell setup allows high-resolution imaging and accurate chemical composition analysis. However, this configuration has intrinsic limitations including the electrolytes adopted being different from those in real batteries, insufficient contact area between the electrolyte and electrode, and inability to decipher the critical SEI formation process. To emulate the operation conditions in a real battery, the sealed liquid-cell configuration is designed for in situ TEM investigations employing a SiNx membrane as the electron transparent windows and common electrolytes (Figure 3b). However, the resolution is downgraded, governed by the thickness of the view windows and electrolytes. To date, due to the ease of fabrication, the primary in situ TEM setup used in SIBs studies is the open-cell platform. Although the processes at the electrodes in the open-cell platform are not strictly electrochemical due to the absence of common electrolytes, visualization of the microstructural/mechanical evolution accompanied by phase transformation and tracking of ion diffusion deem in situ TEM a useful tool to obtain critical localized information upon sodiation/desodiation and failure mechanism. This section will focus on recent progress of in situ TEM in investigations of reaction mechanisms of electrode materials in SIBs and highlights the science accomplished by in situ TEM, discussing challenges and potential future directions.

Figure 3.

Schematic of in situ TEM experimental configurations: (a) open-cell setup and (b) sealed liquid-cell setup.

1.1. Intercalation Reactions

Carbonaceous materials are the most studied intercalation anodes for SIBs due to their highly abundant resources, decent capacity, and stability. Various carbon materials including hard carbon, soft carbon, graphite, and graphene have been studied for Na storage. Na storage mechanisms in these materials remain elusive due to the limitations of the characterization techniques and their complicated structure. First, poor crystallinity in disordered carbons (e.g., hard carbon) indicates that diffraction cannot uncover sufficient information regarding disorder. Second, various types of defects and micropores present different reaction behaviors, and to identify the contribution of these factors individually to battery performance is difficult. Third, the performance of disordered carbon materials is also highly influenced by the electrolyte and SEI. Finally, microstructure variations of disordered carbon materials are closely related to the pyrolysis process, which is complex and challenging to characterize.

To date, a desirable route to characterize the evolution of the host structure and Na ions diffusion is by tracking volume change and formation processes of Na and Na2O in the host structure during reactions.33−37 For example, hard carbon is the most popular anode, which has an amorphous structure with multiple types of storage sites for Na ions. Three Na storage mechanisms have been proposed in hard carbon: adsorption, nanopore filling, and intercalation.38,39 However, the exact voltage ranges for different storage processes are still under debate due to the challenges in characterization. Based on the smaller volume expansion due to Na adsorption compared to that by Na intercalation, Wang et al.40 determined that the sodium storage process in hard carbon undergoes two steps (Figure 4). The first step is Na+ adsorption at high-energy surface sites and defect sites (corresponding to the voltage slope from ∼2 to 0.15 V vs Na/Na+), and the second step is the intercalation process at the curved graphene platelets (∼5% expansion of the average graphene interlayer distance, corresponding to the voltage plateau near 0.15 V). The real-time visualization of volume expansion in hard carbon anode helps to unveil its charge storage mechanisms.

Figure 4.

Sodiation of hard carbon studied by in situ TEM. (a, c) TEM image of the pristine and sodiated hard carbon. (b, d) Corresponding electron diffraction patterns. (e) Illustration of Na absorption and intercalation; the curves show the volume change of the hard carbon during sodiation. Adapted with permission from ref (40). Copyright 2019 Royal Society of Chemistry.

Apart from carbonaceous anodes, most cathode materials also possess layered structures. Various phase transformations and volume changes of cathode materials will occur during Na insertion/extraction, which might lead to battery degradation. To our knowledge, there is lack of in situ TEM studies on cathode materials, and it is hoped that such studies could be conducted in the future to provide in-depth understanding and references for cathode design.

1.2. Alloying Reactions

Alloying type electrodes are sodiated by forming intermetallic compounds between inserted Na ions and host elements, which present high capacity and low sodiation potential. However, a well-known issue associated with alloy-type electrodes is that they usually suffer from serious volume changes during cycling leading to capacity fading.

In situ TEM can provide direct information of electrode morphology change, including volume change and appearance of cracks. The direct imaging of morphological changes is significant to understand the degradation mechanisms of alloy electrodes. Some pure element anodes in the IV and V groups, such as Sn,41 Sb,42,43 Ge,44 and Bi,45 have been studied by in situ TEM, where distinct Na (de)alloying behaviors are elucidated. Meanwhile, complex phase transformation also occurs in alloy electrode materials during electrochemical cycling. Microcosmic information of phase transformation can be identified by in situ electron diffraction, which is extremely useful when reactions involve multiple intermediates and sometimes amorphorization. For example, Sn undergoes reversible two-step phase transformations during sodiation/desodiation, involving the formation of an amorphous intermediate NaxSn and the fully crystallized Na15Sn4 phase (Figure 5a).41 From these in situ investigations, the phase transformation is accompanied by large volume changes during electrochemical cycling, which results in quick capacity fading. These findings indicate that the application of pure alloying-type elements as electrodes may not be promising, and optimizations of electrode and electrolyte need to be considered.

Figure 5.

In situ TEM studies for alloying electrode materials in sodiation/desodiation cycles. Microstructural evolution of the (a) Sn nanoparticles. Reprinted with permission from ref (41). Copyright 2012 American Chemical Society. (b) Microstructure evolution during sodiation in SnSb thin-film anodes. Adapted with permission from ref (47). Copyright 2019 American Chemical Society.

One approach to mitigate volume expansion of pure element alloying-type electrodes is to add (in)active elements forming intermetallic compounds. However, when alloying/dealloying with Na, different elements have different electrochemical reaction kinetics, leading to a more complex reaction process than that of a pure element electrode. For instance, in the binary β-SnSb intermetallic electrode, Sn and Sb are sodiated sequentially rather than simultaneously, leading to discontinuous increases in the diameter of the nanowire.46 In addition, Unocic and co-workers investigated the sodiation kinetics of nanocrystalline SnSb thin film and observed during in situ sodiation the electrode initially underwent amorphorization.47 They further quantitatively analyzed the sodiation kinetics using time-lapsed bright-field TEM images to extract Na+ diffusion coefficient and suggested that microstructural changes play a critical role in Na+ transport (Figure 5b).

1.3. Conversion Reactions

Materials such as TM oxides, sulfides, and fluorides, which are based on conversion mechanism, are another prospective class of electrode candidate for SIBs owing to their high specific capacity. However, conversion-type electrodes normally suffer from severe capacity decay, low ionic/electronic conductivity, poor initial Coulombic efficiency, and relatively large volume change.48 Understanding of fundamental reaction mechanisms in this family of electrode materials is still challenging due to reasons such as formation of amorphous intermediates. The volume expansion and corresponding cycling performance in conversion electrodes are related to their complex phase transformations. These changes can be directly visualized by in situ TEM during Na+ insertion/extraction. Especially, detailed local crystallographic information, heterogeneous reaction processes, and subtle structural changes can be probed by electron diffraction and fast Fourier transform (FFT).

In situ TEM can capture the reversible metallic phase formation in some conversion metal oxide electrodes, such as Co3O4,49,50 NiO,51 and ZnO.52,53 It is found that metal nanoparticles after oxide reduction are interconnected to form a metallic network and disperse within Na2O matrix, providing a good electron pathway. However, the Na2O that formed during sodiation can block further transport of Na+, and the quantity of Na2O will gradually accumulate as the cycle progresses, leading to deteriorated diffusion kinetics. Irreversible volume change also occurs during Na+ insertion/extraction, further degrading host materials. In addition, crystallographic defects, including point defects, line defects, and planar defects, are usually generated during electrochemical process, which may change the mechanical and electronic properties of host materials. Compared to other characterizations, in situ high-resolution TEM (HRTEM) can capture these defects directly. Defects in crystal lattice are often considered to reduce battery performance, but in situ TEM studies found that defects are somehow conducive to improving SIBs reaction kinetics. For instance, high-density dislocations in polycrystalline ZnO nanowires enable improved ductility and thus the cycling performance of the ZnO/Na cell.52 Performance optimizations are expected to benefit from these findings by utilizing crystal defects (vacancies, dislocations, stacking faults, interfaces, etc.) produced during cycling and material synthesis.

In situ TEM is powerful to track microstructural changes of chemically identical electrode materials upon sodiation. Xu et al.53 investigated the sodiation behaviors of single-crystalline (sc) and polycrystalline (pc) ZnO nanowires (ZNWs). In situ TEM distinctly showed that while the non-uniform sodiation in sc-ZNWs manifested a slow step-by-step propagating displacement reaction front as well as the generation of heterogeneous interfaces, pc-ZNWs underwent ultrafast sodiation which possibly was associated with unobstructed ionic transport pathways among ZnO nanograins. The results highlight the benefit of in situ TEM to probe different microstructural responses in chemical identical electrode materials under operation.

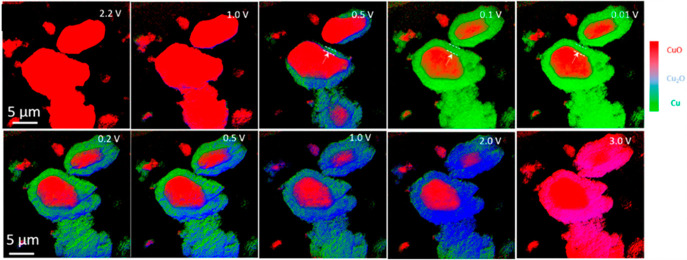

In situ TEM can be used to probe reaction intermediates of complex reactions and monitor the reversibility of conversion electrodes. Xia et al.54 studied the chemo-mechanical dynamics of α-MoO3 nanobelts which undergo multi-step phase transitions and volume changes during electrochemical cycling (Figure 6). During the first sodiation, the orthorhombic α-MoO3 transforms to amorphous NaxMoO3, followed by the formation of the crystalline NaMoO2 phase, then further transformed to the final mixture of crystalline Mo nanograins and Na2O. By tracking the swelling of the nanobelt at different time, the conversion reaction rates are measured in the range of 1–30 nm s–1. Upon the next desodiation, the sodiated products are consumed but not fully transformed back to the pristine state, indicating that an irreversible phase transformation occurred in the first cycle. The phase transformation afterward is reversible between crystalline Mo and amorphous Na2MoO3. The volume expansion is 27% after the first sodiation and 16–19.5% during subsequent cycles, giving rise to the different Coulombic efficiencies during cycling. Such first-cycle irreversible phase transformations have also been observed by in situ TEM in the NiCo2O4,55 CuO,56−58 and MnO2,59,60 as well as some metal sulfides/selenides, like Ni3S2,61 FeSe,62 Cu2S,63 and Co9S8.64

Figure 6.

In situ TEM investigation of the microstructural evolution of conversion-type α-MoO3 electrode during Na diffusion. Reprinted with permission from ref (54). Copyright 2016 Elsevier.

1.4. Mixed Reactions

In addition to single-reaction mechanisms, certain electrode materials exhibit more than one reaction mechanism. As discussed above, reaction mechanisms of different types of materials can be revealed by in situ TEM (either imaging mode in real space or diffraction mode in reciprocal space) and at various length scales (from micron scale to nanoscale). Meanwhile, ultra-fast acquisition time ensures temporal resolution to monitor the dynamic reaction processes; thus, in situ TEM analysis is expected to empower researchers to elucidate complex and heterogeneous electrochemical reactions with more than one type of charge storage mechanisms.

Phosphorus-based materials are intercalation-alloying-type electrodes, possessing high theoretical capacity (e.g., 2596 mAh g–1 for P) and low redox potential.65 P-based materials with open space in their crystal lattice allow the intercalation of Na+ prior to alloying reactions. Nevertheless, serious structural changes and poor electronic conductivity of the electrodes tend to induce electrode pulverization and thus rapid capacity fade. Recently, Sun et al.66 revealed that intercalation and alloying-type reactions dominate in black phosphorus for Na storage. The in situ TEM observations before and after sodiation show that intercalation is achieved by Na+ insertion into phosphorus layers along the x-axis-orientation channel. The alloying reaction leads to high specific capacity but reduces cycling performance due to anisotropic expansion during sodiation. In other in situ TEM investigations, it is found that this anisotropic expansion arises from anisotropy of Na diffusion and insertion strain in black phosphorus.67,68

Some conversion-type materials with open sites in their crystal lattices, such as FeP,69 TiS2,70,71 MoS2,72,73 FeS2,74 and CaV4O9,75 undergo an intercalation reaction prior to the conversion reaction. Multi-step reaction behaviors are observed in these materials by in situ TEM. For example, in 1D shape polycrystalline FeS2 nanotubes, Na intercalation in spinel FeS2 results in the formation of crystalline NaFeS2 in the early stages of sodiation while further Na interclation converts NaFeS2 into Fe and Na2S (Figure 7).76 Upon following desodiation, the as-formed Fe and Na2S transformed to crystalline NaFeS2 rather than pristine FeS2. This conversion reaction between NaFeS2 and Fe/Na2S is reversible after the first cycle.

Figure 7.

Intercalation–conversion reaction: FeS2. Reprinted with permission from ref (76). Copyright 2019 Elsevier.

For some conversion-type electrodes, if the metal cation can react with Na (e.g., Sn, Sb, and Bi), the sodiation process usually undergoes an intercalation–conversion–alloying reaction pathway and exhibits different reaction kinetics during various reaction steps.77−82 Such differences are probably caused by the difference in mobility of Na+ in different lattice frames.83 Thus, it is necessary to further understand the differences in various conversion-type materials by in situ TEM. These in situ TEM findings, especially the localized morphological and structural characteristics at nanoscale, support structural engineering and surface modification on the improvement of the cycling stability of the conversion-type electrodes.

1.5. Thermal Stability and Mechanical Property

In principle, structural changes might originate not only from the Na+ insertion into the host but also from the increase of temperature, which might cause battery degrade. At high temperature the material breakdown is normally accompanied by remarkable oxygen evolution, resulting in thermal runaway with flammable electrolytes.84,85 Thus, it is important to understand the intrinsic thermal behaviors of electrodes during operation. An in situ heating chip in the unique TEM holder can precisely control the temperature and heating rate, which can be applied to reveal the thermal degradation process of electrodes.

Recently, Liu et al.86 quantitatively analyzed the thermal degradation processes of mechanically exfoliated 2D black phosphorus by in situ (S)TEM and found that the crystal structure of the black phosphorus flakes appear unchanged when the annealing temperature is below 400 °C (Figure 8a). Amorphization occurs after annealing above 400 °C, and the flake remains amorphous after holding at 500 °C for 20 min. Black phosphorus degradation proceeds by sublimation, which occurs at edges/defects of flakes and propagates as eye-shaped cracks, rather than melting.

Figure 8.

(a) In situ heating of black phosphorus. Adapted with permission from ref (86). (b) In situ compression and unloading processes for a Na particle and (c) in situ tensile tests of a Na dendrite. Reprinted with permission from ref (87). Copyright 2020 American Chemical Society

In situ mechanical testing in the TEM has been widely applied in various bulk materials to study their deformation behaviors and mechanical properties. Through delicate experimental designs, mechanical properties of materials and the corresponding structural evolution can be obtained simultaneously, establishing the relationship between structural and mechanical properties. Recently, this design has been adopted to study the mechanical properties of dendrites in sodium metal batteries. Like Li, Na metal can form dendrites during deposition leading to safety issues. Liu et al.87 reported the in situ electro-chemo-mechanical response of Na dendrites and SEI during cycling via an environmental TEM–atomic force microscopy (ETEM-AFM) platform which allows operation in a CO2 atmosphere. During electrochemical plating, nanostructured Na deposition, approximately Na dendrites, appear but is stabilized by a SEI layer (<20 nm). The surface is predominantly comprised of Na2CO3. The mechanical nature of Na dendrites is measured using in situ compression and tension tests (Figure 8b,c). The compressive and tensile strengths range from 36 to 203 MPa, and Young’s modulus varies from 1.3 to 3.5 GPa. Such dendrites are distinct from bulk Na metal (the stress varies from 0.1 to 0.25 MPa at 8% strain with Young’s modulus of ∼ 3.9 GPa).88 The higher strength in Na dendrites is considered to be a result of the reinforcement of the Na2CO3 SEI layer, which possesses a compressive strength varying from 261 to 682 MPa. The mechanical properties of other SEI components, such as NaF, Na2O can be more focused, as a Na whisker is easier to generate compared to its Li counterpart.

In this section, recent in situ TEM studies of SIB electrodes during cycling are summarized in terms of dynamic phase transformation, structural evolution, reaction kinetics, thermal stabilities, and mechanical properties. While a fundamental understanding can be provided by in situ TEM approach, innovation is necessary for further study: (1) As the “pseudo” electrolyte (i.e., Na2O) typically used in current in situ TEM might not reflect the real circumstance in a SIB, it is necessary to use sealed liquid-cell configuration and design new in situ TEM cells that can mimic the working conditions of practical battery systems. (2) Only individual nanoparticle is observed in most in situ TEM works, inviting questionable representativeness. It is also challenging to observe the effect of the surrounding environment near the particle. Thus, it is necessary to combine in situ TEM with other techniques to gain a holistic perspective both locally and globally in multiple modalities across a large range of length scales. (3) Current in situ TEM setups can only run for a few cycles, which limits investigations of the evolution of electrodes under long-term cycling. (4) The electron beam and the TEM vacuum condition will influence the materials and electrochemical processes involved. Proper operation conditions are critical to less artifacts. (5) The formation of SEI profoundly influences the SIBs degradation, especially for full cell construction. However, there is very limited understanding of the formation and evolution of SEI in SIBs due to the lack of methods that can be used to directly characterize SEI. (6) Compared to Li, Na can be directly imaged by STEM technique, which is a great potential to track Na ion transport during electrochemical reactions. Cryo-TEM excels at characterizing SEI but the low-temperature environment imposes grand challenges on mimicking real cell operation. With the continuous development of electron microscopy, including the application of advanced new techniques in battery systems, such as 4D-STEM, a comprehensive understanding of electrode materials in SIBs could be achieved in the future.

2. In Situ/Operando XRD

XRD is a well-established technique essential to obtain structural information to understand the electrochemical reaction mechanisms of electrode materials. XRD characterization is based on the X-ray elastic scattering by periodically ordered atoms inside a crystalline material, producing constant diffraction patterns that provide average structural information with length scales from angstroms to microns.89 XRD pattern is as unique as fingerprint, which enables routine qualitative analysis for crystalline materials. Detailed structural information on battery materials is obtained by performing refinement, including the symmetry, chemical composition, atomic positions, site occupancies, lattice parameters, etc.90,91In situ/operando XRD is used to monitor the structural evolutions including lattice and atomic occupation change of materials during cycling. Specifically, compared to laboratory XRD and conventional emission spectroscopy, synchrotron-based XRD (SXRD) with higher photon energies and intensities provides stronger penetration power, better signal-to-noise ratios, as well as higher spatial and temporal resolution.92,93 Thus, SXRD greatly shortens the acquisition time (∼10–30 min for laboratory XRD and ∼10 s for SXRD) and enable investigations close to real time (operando). In general, for intercalation electrode materials, there are two typical reaction characteristics: the single-phase solid reaction without phase transformation, namely solid-solution reaction, and the phase-transition reaction mechanisms. In the former reaction, only the shift of initial diffraction peaks can be observed without symmetry change during cycling. In phase transition, the materials undergo symmetry changes leading to new peak appearing or old peak disappearing, depending on symmetry. Due to the popularity of this method, there are several reviews with the focus on this topic in general.92−94 For distinction, this section is mainly focused on the important development and perspectives of the in situ/operando XRD in SIBs. The focus aims to deliver holistic overview of the advancements and challenges of this method in various SIBs operating conditions.

2.1. Intercalation Reactions

In contrast to TEM, XRD can be performed in real battery configurations, allowing for in situ/operando studies at larger length scales.95 A variety of in situ and operando XRD setups have been developed, such as modified coin cell, pouch cell, Argonne’s multipurpose in situ X-ray (Ampix) cell, radially accessible tubular in situ X-ray cell, and capillary-type cell.96In situ/operando XRD has been widely used to probe the structural change and phase transformation of various intercalation-type electrodes. Compared with alloying- and conversion-type electrodes, the structural changes in intercalation-type electrodes are less substantial. For example, adsorption–insertion mechanisms of Na+ into typical carbonaceous materials were studied by Qiu et al.97 combining high-resolution in situ XRD and other techniques, as well as simulations. Na+ intercalates into the regions of graphene layers with relatively wide spacing, resulting in relatively large interlayer spacing, reflected by the Bragg peak at lower angle (Figure 9a). Another part of graphite layers with narrow spacing hardly allows Na+ intercalation; thus, the Bragg peak remains in its initial position. The split reflections merge into a single peak during Na extraction, indicating reversible structure change.

Figure 9.

In situ/operando XRD investigations in intercalation-type electrode materials. (a) In situ XRD mapping of hard carbon anode during the first cycle at 200 mA g–1 at room temperature. Adapted permission from ref (97). Copyright 2017 Wiley. (b) Operando XRD of P2-Na2/3MnO2 (top panel) and P2-Na2/3[Mn0.8Co0.2]O2 (bottom panel). Reprinted with permission from ref (111). Copyright 2019 American Chemical Society. (c) In situ XRD of Na1.2Ni0.2Mn0.2Ru0.4O2 (left panel) and the corresponding lattice parameters evolutions (right panel). Adapted with permission from ref (120). Copyright 2018 Elsevier. (d) In situ XRD of the Na3MnTi(PO4)3 cathode cycled at 50 mA g–1 and schematic illustration showing Na+ (de)intercalating from/into Na3MnTi(PO4)3 cathode upon electrochemical processes. Adapted with permission from ref (122). Copyright 2019 Wiley. (e) 2D contour map of (012) reflection plan of Na2-xFeFe(CN)6 (top-left panel), and normalized volume during cycling obtained from in situ SXRD patterns (bottom-left panel), as well as (012), (110)/(104), and (024) reflection planes of in situ SXRD patterns (right panel). Reprinted with permission from ref (123). Copyright 2020 Springer Nature.

Ti-based compounds are widely studied as anode for SIBs, which store Na through intercalation-type reaction. Recently, from in situ (S)XRD findings, it is found that Ti oxides with different polymorphs exhibit different reaction kinetics. Anatase TiO2 undergoes an irreversible amorphization upon the first sodiation, and the amorphous phase yields pseudocapacitive sodium storage mechanisms upon subsequent cycles.98 However, TiO2-B electrode with monoclinic structure undergoes a single-phase reaction upon sodiation/desodiation cycles, yet a portion of the intercalated Na+ is not reversibly extracted from TiO2-B structure, resulting in an unfavorable initial Coulombic efficiency.99

Layered transition metal oxides are another intercalation-type electrode material for SIBs. According to the Na coordination environment (prismatic and octahedral) and the packing sequence of oxygen layers (ABBA and ABCABC), layered transition metal oxides are usually categories following the notation by Demas: P2-type and O3-type.100 It is well known that there are often complex crystal structural changes and multi-phase transitions in various layered metal oxide structures, which have considerable impacts on SIBs performance. In situ/operando XRD identifies crystal structure of bulk electrode materials during cycling, including phase, lattice parameter, atomic position, site occupancy, stacking faults, strain, and texture, which reveals the effect of these evolutions on SIBs performance.

P2-type cathode materials have large prismatic sites for Na+ which often undergo undesired P2- to O2- or P′2 (OP4)-type phase transformation in high-voltage regions, causing rapid capacity decay. This phase transformation reaction mechanism has been elucidated by in situ/operando XRD in different P2-type electrode materials, such as Na2/3Ni1/3Mn2/3O2,101,102 Na0.44MnO2,103 Na0.75Ni0.22Co0.78O2,104 Na0.7Fe0.4Mn0.4Co0.2O2,105 Na2/3Mn0.8Fe0.1Ti0.1O2,106 Na0.7[Cu0.15Fe0.3Mn0.55]O2,107 Na0.66Li0.18Mn0.17Mg0.21Co0.08O2,108 etc. In order to mitigate this problem, other elements have been adopted to substitute Na sites or TM sites and suppress the P2-O2 phase transition for better electrochemical performance.109 For instance, Xiong et al.110 recently investigated the effect of Li doping on the electrochemical properties of P2-Na0.67Ni0.33Mn0.67O2 cathode. It was found that Li occupancy on different sites (Na sites and/or TM sites) in the P2 structure has different effects on the crystallographic stability and electrochemical performance. According to the operando SXRD measurements, these different effects lead to the different structural stability (relates to lattice parameters change) during cycling. Myung and co-workers studied the influence on different content of Co dopant in P2-Na2/3MnO2 and probed the structural change of optimal P2-Na2/3[Mn0.8Co0.2]O2 compound via operando XRD.111,112 The whole cycling process of the P2-Na2/3[Mn0.8Co0.2]O2 electrode exhibits a typical single-phase reaction, which is accompanied by only peak shifts and no new peaks appearance (Figure 9b). Regarding the P2-Na2/3MnO2 compound, besides the peaks shift, a new phase arises around 37.5° during discharge, which is recognized as the phase evolution from the P2 to P′2 phase. Operando XRD results revealed that the Co-doped material can maintain the initial P2 structure, leading to a small volume change. Likewise, the substitution of Cu,113 Zn,114 Mg,115 as well as co-substitution of Cu and Mg116 for Ni in P2-Na2/3Ni1/3Mn2/3O2 can also endows P2 phase by less severe phase transformation, contributing to improve structural reversibility.

Compared to the P2-type structure, the O3-type structure has a higher Na content, and Na+ ions reside at octahedral sites. In situ/operando XRD studies show that there is often a series of biphasic, triphasic, and solid-solution multi-phase transformations from O3- to P3- and to O′3-type structures which cause capacity fade.117 The addition of a certain amount of dopants can also improve the O3-type structural stability.118,119 Su et al.120 reported a ruthenium substituted sodium-excess O3-type Na1.2Ni0.2Mn0.2Ru0.4O2 cathode, which shows enhanced cycling stability. The material undergoes the sequential phase transitions of O3–O3′ (a new hexagonal O3-type phase with a larger (001) interplanar distance compared to the pristine O3 structure)–P3 during charge and P3–O3′ during discharge in the first cycle (Figure 9c). In the subsequent cycles, the single reversible phase transformation between P3 and O3′ dominates, leading to the smooth voltage curve and cycle stability of the Na1.2Ni0.2Mn0.2Ru0.4O2.

Besides layered transition metal oxides, polyanionic compounds (Na superionic conductor compounds (NASICON-type), pyrophosphates, mix-polyanion) and Prussian blue analogues are also used for Na storage due to their open framework structure which could easily accommodate sodium ions. Recently, Mai’s group used high-resolution in situ XRD to study the phase transformation behaviors in a NASICON-type cathode material of Na3V2(PO4)3 at different scan rates and different temperatures.121 The materials form a one-phase solid solution upon desodiation rather than common two-phase reactions. They later designed another NASICON-structured Na3MnTi(PO4)3 cathode for SIBs and found that both solid-solution and two-phase transformation reactions occur in this material during electrochemical cycling.122 As illustrated in Figure 9d, the diffraction peaks (104), (113), (204), and (300) exhibit reversible shifts during cycling, indicating a solid-solution reaction. Meanwhile, presence/absence of (211) and (116) peaks indicate a biphasic reaction. Wang et al123 fabricated a series of sodium-rich Prussian blue Na2-xFeFe(CN)6 for SIBs and investigated their electrochemical reaction mechanisms. Based on in situ SXRD investigations, the highly reversible three-phase transformations between rhombohedral, cubic, and tetragonal are observed during Na+ (de)intercalations (Figure 9e).

2.2. Alloying and Conversion Reactions

In addition to intercalation-type electrode materials, in situ/operando XRD has also been used to study the electrochemical reaction mechanisms of various electrode materials based on alloying and conversion reactions, as well as complex mixed reactions involving two or three reactions. Although in situ TEM has revealed complex reaction mechanisms during sodiation/desodiation, in situ and operando XRD studies provide more realistic pictures of the reaction process on a global scale. For example, in the case of alloying reactions, Palaniselvam et al.124 studied the (de)sodiation reaction mechanisms of tin-carbon composite anodes using in situ XRD. A gradual disappearance of the Sn diffraction peaks along with the appearance of some new broad reflections during discharging, indicating that several Na-Sn intermediates with limited crystallinity are formed during sodiation (Figure 10a). This behavior is in agreement with their recent findings125 and the results from Obrovac and co-workers.126 The reaction partially reverses during desodiation, as several unknown intermediates appear again until the final Sn forms. These (de)alloying reaction mechanisms were also demonstrated in other alloying-type anode materials using in situ/operando XRD studies, such as Bi,127 Sb,128 Pb,129 SnSb,130 Bi-Sb alloy,131 and Fe-Sb intermetallic alloy.132

Figure 10.

In situ/operando XRD in alloying-type and conversion-type electrode materials. (a) In situ XRD patterns of Sn and corresponding voltage profiles. Reprinted with permission from ref (124). Copyright 2019 Wiley. (b) In situ XRD of MoP during the first cycle at a voltage range between 0.01 and 3.0 V. The green and red curves represent the charge and discharge process. Reprinted with permission from ref (134). (c) In situ XRD of Sb2Se3 during the initial cycle and schematic of the reaction mechanism during charge/discharge process. Adapted with permission from ref (138). Copyright 2017 Wiley.

In the case of conversion-type electrode, some direct conversion reactions observed by in situ TEM have been supported by in situ XRD investigations.133 For example, according to the in situ XRD patterns, the MoP anode undergoes a typical conversion-type reaction (Figure 10b).134 It is noted that minor peaks of Na3P and Mo are observed after the first cycle, indicating incomplete reversibility of MoP anode. In some electrode materials with mixed reactions, in situ/operando XRD analysis also provides detailed information in reaction pathways.135−137 For example, the in situ XRD of Sb2Se3 nanorods anode shown by Ou et al.138 presents typical initial intercalation and subsequent conversion and alloying reactions. According to the reaction sequence (Figure 10c) revealed by cyclic voltammetry, a six-stage reaction mechanism can be derived. When the battery is discharged to 1.1 V (first stage), the peaks of Sb2Se3 shift to lower 2θ, suggesting the Na+ intercalation into host materials and the formation of intermediate NaxSb2Se3. When discharged to 0.6 V (second stage), the peaks of Sb2Se3 become gradually weakened in intensity until complete disappear accompanying with the appearance of new peaks of Na2Se and Sb, indicative of conversion reaction from NaxSb2Se3 to Na2Se and Sb. When the battery is fully discharged to 0.01 V (third stage), the new peaks of NaSb and Na3Sb appear, implying that the alloying reaction occurs between Na+ and Sb. During the subsequent charging process, the reverse phase transformations sequentially occur, which are in agreement with the results of electrochemical measurement.

2.3. Thermal Behaviors

In situ/operando XRD also facilitates studying thermal behaviors of electrode materials during synthesis and electrochemical processes. Unlike the vacuum environment of TEM, in situ heating XRD can be operated in ambient condition, thus providing more accurate information during the synthesis process of electrode materials. Ma et al.139 studied the formation mechanism of the P2-type Na2/3MnO2 phase during the solid-state synthesis by in situ high-energy XRD. Before sintering, the pristine powder consists of Na2CO3, MnCO3, and Mn3O4 (Figure 11a). On the basis of the in situ XRD results (top panel) and corresponding covariance analysis (bottom panel), the solid-state reaction occurs at two temperature ranges: 270–300 °C and 550–710 °C. Multiple intermediates are formed during the lower temperature range, and the P2-type Na2/3MnO2 phase appears at about 600 °C. At the end of the heating (900 °C), the diffraction peaks of the O′3-type NaMnO2 phase are observed. The findings highlight the importance of elaborate synthesis parameters modulation enabling high-performance cathodes.

Figure 11.

In situ/operando XRD investigation during materials synthesis and for thermal stability of electrode materials. (a) Contour plot of in situ XRD patterns collected during the solid-state synthesis and corresponding covariance analysis. Reprinted with permission from ref (139). Copyright 2017 Elsevier. (b) Contour plots of high-temperature in situ XRD patterns of charged state NaxNi2/3Sb1/3O2 electrode and corresponding selected diffraction patterns. Reprinted with permission from ref (140). Copyright 2017 Elsevier.

In addition, thermal stability is another important aspect to consider in SIB applications. To understand the thermal behaviors, Dai et al.140 used high-temperature in situ XRD to probe structural evolution of the desodiated NaNi2/3Sb1/3O2 electrode as a function of temperature between 100 and 500 °C. The material exhibits no sign of phase transformation or new phase formation, only gradual changes in diffraction peaks to lower 2θ angles during heating processes, indicating that this structure is relatively stable within the high temperature range (Figure 11b). Though thermal runaway issue in SIBs is less severe compared to LIBs, stability in electrode materials under extreme temperatures is still recommended.

Overall, in situ/operando (S)XRD technique has been used in various aspects of SIBs, including elucidating electrochemical reaction mechanisms, degradation mechanisms, thermal stability, and the solid-state synthetic process of electrode materials (mostly cathodes). For lab-based XRD, the acquisition rate or the temporal resolution is far inferior to that of high-speed synchrotron-based XRD. Therefore, SXRD is strongly recommended for accurate analysis. Following with elaborate refinements, the information obtained from this technique enables an atomic understanding of the structural evolution. The power of X-ray diffraction is far beyond the aforementioned applications. In light of better spatial resolution, Bragg coherent diffraction imaging (BCDI) of much smaller beam size is capable of resolving the strain and morphological information for isolated single crystals. For sufficient temporal resolution, ultrafast SXRD can be implemented in the case that the metastable phase cannot be captured, especially for those multi-phasic reactions. Although in situ/operando (S)XRD techniques previously designed for LIBs can be readily applied for SIBs, there is still room for improvement from different aspects. For example, to realize interaction between active materials and X-rays, punched hole(s) are often fabricated on in situ/operando cells. The hole(s) covering with insulating materials may cause precarious pressure and hamper the electrical connection. As the photon energy is high (transmission mode), if applicable, pouch cell can be performed for in situ XRD experiments. In a word, the hardware design of in situ/operando configurations should be stabler and more adaptable. As a diffraction-based technique, the intrinsic disadvantage is apparent: it is knotty to address materials of poor crystallinity; therefore, a combination of other techniques that can probe local information and materials’ lack of long-range order can provide more comprehensive information, which will be introduced in the following sections.

3. In Situ/Operando XAS

XAS is a synchrotron-associated characterization technique. Unlike XRD, XAS does not require long-range order in materials for characterization—that is, it works equally well in amorphous materials, crystalline solids, and liquids. The basic principle of XAS based on how strongly selected elements within a material absorb X-rays as a function of X-ray energy. This reduction is described by the absorption coefficient according to Beer’s law, i.e., It = I0 e–μ(E)t, where μ(E) is the absorption coefficient that is related to the photon energy, It and I0 represent the intensities of transmitted and incident X-rays, and t is the thickness of the sample.141 The XAS data analysis usually falls into two regions: the X-ray absorption near-edge structure (XANES) and the extended X-ray absorption fine structure (EXAFS).142 The XANES region is located in the range of 5–150 eV from the ionization edge, which displays a sudden jump in the spectrum due to the strong absorption of X-ray. It provides chemical and structural information, such as the oxidation state, orbital occupancy, and symmetry. The EXAFS region comprises the energy range beyond the absorption edge, which reflects local atomic structure. To be more specific, the bond distance, coordination number, and type of neighboring atoms can be known. These two regions are dependent on the incident X-ray energy and the atomic number (Z) of elements; thus, a method called fingerprinting is used to match the XANES spectrum of unknown material to those of foregone species.143 In addition, XAS is usually divided into hard XAS (hXAS) and soft XAS (sXAS) according to the energy range of the synchrotron X-ray. The hXAS energy is above 5 keV and covers the K-edges of TM elements, while the sXAS energy is between 100 eV and 3 keV and covers the K-edges of light elements (include B, C, N, O, and F) as well as the L-edges of TM elements.144 There is also an intermediate region (2–7 keV), namely tender X-ray, which can probe the narrow solid–liquid interface but by exploiting photoelectron emission rather than measuring absorption.145 The following subsections discuss the application of in situ/operando hard/soft XAS in the bulk and surface chemistry, especially the charge compensation mechanisms of SIB electrode materials.

3.1. In situ/Operando hXAS

hXAS is a bulk-sensitive technique which can be used in transmission and fluorescence modes. A synchrotron radiation source of high brightness can penetrate materials with proper thickness to probe atoms, molecules, and chemical bonds. For example, in the most commonly used transmission mode, synchrotron light can well probe a homogeneous sample when its total thickness is below 2–3 absorption lengths (the absorption length is proportional to 1/μ(E)). In addition, the hXAS does not need an ultra-high-vacuum environment and has short characteristic time (a few seconds to tens of seconds), which is suitable for operando studies of SIBs.

3.1.1. Intercalation Reactions

Most electrochemical reactions involve electron transfers, resulting in the change of oxidation state and sometimes formation of intermediate amorphous phases. Like other in situ/operando techniques, in situ/operando hXAS has been successfully employed in various SIB systems, which is focused on investigation of the dynamic charge compensation as well as electronic structure evolution of materials during electrochemical processes.94,146

The intercalation reaction mechanism in TiO2 has been confirmed in LIBs, but the Na storage mechanism in TiO2 remains controversial. Recently, Fehse et al.147 revealed that the sodiation of anatase TiO2 is primarily based on the Ti4+/3+ redox and accompanied by an irreversible change of the pristine structure (Figure 12). The sodiation of anatase TiO2 proceeds through the following reaction mechanisms: upon the first sodiation process, TiO2 + xNa → “NaxTiO2”, and during subsequent cycles, “NaxTiO2” ↔ “TiO2” + “NaxTiO2” + Na, where the quotation marks in the reactions refer to amorphous or disordered phases or both. Siebert et al.148 further quantified the amount of reversible and irreversible Na ions inserted into a anatase TiO2 electrode based on an analytical fit and principal component analysis with a linear combination analysis (LCA) of operando XANES data at the Ti K-edge. The irreversible loss of the structural ordering are responsible for the low Coulombic efficiency during the first cycle.

Figure 12.

(a) Observation of Ti K-edge XANES of TiO2 anatase structure. Dashed line and dashed-dotted line present the end of first charge and end of charge positions. The inset panel is the evolution of the pre-edge features. (b) Corresponding electrochemical cycling curves. Reprinted with permission from ref (147). Copyright 2020 MPDI.

Most TM-based cathode materials of the SIBs also proceed through the intercalation reaction mechanism. In general, TMs are heterovalent elements, which occur in a wide range of formal oxidation states during sodiation/desodiation. In order to restrain the unfavorable phase transformation and stabilize the structure, the multi-TM-cation substitution or doping approach is employed. These TMs with special electronic structures, especially their absorption energy close to each other, are ideal targets for the in situ/operando hXAS investigations. In addition, the distribution of elements at multiple crystal sites in TM oxides may influence the batteries performance. The structure fitting and analysis of EXAFS can confirm the coordinated atoms, pertinent bond lengths, and ratio of different atomic occupancies.149 These crystal site occupancies require local or short-range information that are difficult to be identified by XRD. In combination with in situ EXAFS analysis and corresponding electrochemical experiments, the roles of the metal elements at specific crystal sites can be well understood.

The following discussion is restricted to the application of in situ/operando hXAS characterization in TM-based cathode materials. The exact valence can be readily calculated from the reference based on the linearity between energy shift and oxidation state. In most reports, Mn remains in the +4 oxidation state in the layered oxides during cycling, showing minor participation in the electrochemical reaction.150,151 The main function of the Mn in layered oxides is to stabilize the host structure, which provides a negligible contribution to the charge compensation. However, some recent studies found that the redox pair of Mn4+/Mn3+ involves in the charge compensation process with other TMs, and its activity depends on the cutoff voltage.152,153 Co exhibits typical redox behaviors as a key contributor to the charge compensation mechanism during Na insertion and extraction. For example, in P2-Na0.74CoO2 electrode, the sodium intercalation/deintercalation proceeds with the Co3+/Co4+ redox reaction,154 and the Co3+/Co2+ redox pair is involved in the charge compensation process of a P2-Na2/3Co2/3Mn1/3O2 electrode.152 Ni is also found to be electrochemically active in layered oxide materials but is electrochemically inactive in Prussian blue analogue materials. The Ni2+/Ni4+ redox couple is the main charge compensation contributor at the TM sites during Na ions intercalation/deintercalation in a P2-type Na0.78Ni0.23Mn0.69O2 cathode (Figure 13a)151 but is electrochemically inactive in a Prussian blue material Na2Ni(II)[(Fe(II)CN6) (no remarkable changes of Ni K-edge position in operando XANES data (Figure 13b), indicating that the capacity contribution of Ni is negligible).155 Ni2+/Ni4+ redox couple is active in layered oxides with mixed structures of P2/P3/O3-NaxMn0.5Ni0.3Fe0.1Mg0.1O2 materials.156 Other Ni redox pairs, such as the Ni2–3/Ni4+150 and the Ni3+/Ni4+,157 were also proved to be active via in situ/operando XANES. Likewise, the Fe2+/Fe3+ redox reaction is well established in iron phosphate cathodes,158 where the cationic/anionic redox reactions in iron-based layered oxides are complex. For instance, the iron-based layered oxides are inactive materials in LIBs but exhibit reversible capacity in SIBs. From the in situ and ex situ XANES results, the charge compensation of the layered NaFeO2 material occurs through the oxygen redox activity during Na insertion and extraction, rather than through the Fe3+/Fe4+ redox reaction.159 However, it was reported that the Fe3+/Fe4+ redox activity is responsible for charge compensation in some layered binary NaxFeyTM1-yO2 structure153 and ternary NaxFeyTMzTM′1-y-zO2 compounds.156,160 The Fe redox and anionic activity can be a future directions for SIB cathodes.

Figure 13.

In situ/operando XANES at Ni K-edge XANES of the (a) P2-type Na0.78Ni0.23Mn0.69O2 material. Reprinted with permission from ref (151). Copyright 2017 American Chemical Society. (b) Prussian blue analogue. Reprinted with permission from ref (155). Copyright 2020 American Chemical Society.

3.1.2. Alloying Reactions

In situ/operando hXAS is also suitable for tracing alloying reactions. Darwiche et al.161 used operando hXAS to investigate the dynamic behaviors of Sb electrode during the first three cycles (Figure 14a). Despite slight changes in overall shape of the XANES region, the oscillation of EXAFS spectra is notable during different cycling processes due to a low energy resolution of the absorption Sb K-edge. During the first sodiation process, the crystalline Sb gradually turns into a disordered Na3Sb phase accompanying the amorphization of Sb; during the subsequent desodiation process, the Na3Sb phase transforms back to the amorphous Sb rather than pristine crystalline Sb. This amorphous Sb can reversibly transform into Na3Sb phase in the second sodiation process. In addition, the model-based EXAFS analysis can be further used to detect the reaction kinetics in bimetallic electrodes. Fehse et al.162 investigated binary SnSb electrode with Sn and Sb K-edges during cycling. From the evolution of EXAFS spectra during sodiation process (Figure 14b), the changes of Sn and Sb do not occur synchronously, suggesting a complex multi-step alloying reaction process: (1) the sodiation of Sb first occur—the Sb in the pristine SnSb phase transforms to the Na3Sb phase and an unstable intermediate phase of nanosized metallic Sn (α-Sn); (2) as the reaction continues, the Sn gradually transforms to Na15Sn4 phase. Furthermore, EXAFS fingerprints demonstrate that the amorphous SnSb generate after a complete cycle is different from the pristine SnSb phase.

Figure 14.

(a) Operando Sb K-edge XANES and EXAFS spectra collected during the first one and a half cycles. Reprinted with permission from ref (161). Copyright 2018 Batteries MDPI. (b) Operando Sn and Sb K-edge EXAFS spectra measured during the first three cycles. Reprinted with permission from ref (162). Copyright 2018 Royal Society of Chemistry.

3.1.3. Conversion Reactions

As mentioned above, degradation mechanisms of conversion-type electrode materials are generally arising from the irreversible phase transformations, volume change, and reaction kinetics. The effects of phase transformation and volume change have been demonstrated in various in situ/operando XRD and in situ TEM studies. The coupling of in situ/operando XAS is helpful in reflecting the electronic structure information on the bulk of electrodes in real cells with conventional liquid electrolytes, providing a quantitative assessment of reaction kinetics in various conversion-type materials, such as crystallography-dependent kinetics163,164 and morphology-dependent kinetics.165,166 For instance, combined with operando XAFS, XRD, and small-angle X-ray scattering analysis, Xu et al.167 shed light on the structural evolution of porous cobalt oxide materials (composed of two phases: Co3O4 and CoO) during sodiation. As shown in Figure 15, no evident changes are observed during the first and second sodiation cycles, from either crystal structure changes in EXAFS or valence states evolution in XANES analysis, which is attributed to the sluggish transportation of Na ions into the bulk material hindered by the large radius of Na ion and the intrinsic large sodiation barrier of cobalt oxides.168 Therefore, a large anion framework is required to boost Na diffusion and conversion reaction kinetics, such as replacing metal oxides with metal sulfides. It has been proved that cobalt sulfides exhibit greater electrochemical activities than that of cobalt oxides (the Co reduction from Co+1.78 to Co0 was evidenced by in situ XANES of Co9S8).169

Figure 15.

Operando XANES spectra and corresponding EXAFS analysis along with discharge/charge profiles of porous cobalt oxide electrode. Reprinted with permission from ref (167).

Overall, in situ/operando hXAS techniques provide opportunities to describe the local structural changes in battery materials during continuous cycling, such as charge transfer and changes in bond length and local coordination environment. However, this technique is insensitive to light elements due to the energy limit. Being an element-sensitive characterization, information on long-range order is unavailable. Therefore, a combination of the electrochemical and other complementary characterizations is crucial to more comprehensive understandings regarding the complex phenomena that emerge during SIB operation with different aspects of physical/chemical changes and at multiple length scales. In the in situ experiments, due to the auxiliary cell components, the transmission mode sometimes cannot offer sufficient signal as the X-ray energy is not as high as that in XRD. The fluorescence signal can be also problematic, dependent on the hole size, sensitivity of detector, and the self-absorption effect. For EXAFS-needed measurements, as the acquisition time is 10–20 min, depending on different k ranges, a hold at certain voltage must be applied for the materials.

3.2. sXAS for Surface Studies

sXAS is a sensitive spectroscopic technique resolving electronic structure from subsurface to surface, using synchrotron X-ray energy from 100 eV to 2 keV (no absolute boundary is set, 3 keV is also proposed as the upper limit).170 Similar to hXAS, sXAS is an element-specific characterization that can be combined with XRD, TEM, etc. While both probing unoccupied states, sXAS for TM delineates a 2s-3d transition (L-edge), unlike the 1s-4p transition as K-edge in hXAS. Therefore, sXAS can provide direct and precise interpretation for the oxidation state and spin state of TM, the building blocks for numerous SIBs electrodes. Anchored by lower energy of incident photon, besides L-edge of TM, K-edge (1s-2p transition) of low-Z elements such as Na, C, N, and O can be readily covered. Overall, capable of resolving light elements (K-edge), anodes free of TM can be investigated, from carbon families to multiple alloy-type and conversion-type materials. Specifically in oxides, pre-edge of O K-edge symbolizing the hybridization effect between O 2p and TM 3d orbitals can provide useful information, in combination with the valence change of other elements in electrodes.171 In addition, chemical environments can be resolved in sXAS, from the surface (down to 1 nm) to the subsurface (around 100 nm). To realize this function, either fluorescence or electron signal is detected, originating from distinct relaxation processes.172 The former includes total fluorescence yield (TFY), partial fluorescence yield (PFY), and inverse partial fluorescence yield (iPFY), whereas the latter consists of total electron yield (TEY), partial electron yield (PEY), and Auger electron yield (AEY). The TFY mode is subsurface-sensitive with a probing depth of 50–100 nm depending on the sample.173 However, it usually suffers from self-absorption and saturation effects, which is minimized by iPFY. In contrast, TEY mode probes a depth of a few nanometers and partial electron yield is even more shallow, attributed to the limited escaping depth for electrons compared to photons depending on mean free path.174 Generally, TFY and TEY are popular detection modes for SIBs research in the past decade while the most surface-sensitive AEY is less. The instrumentation of operation modes can be checked in several reviews, which is not the focus here.170,172

To the best of our knowledge, there has not been a comprehensive employment of in situ/operando sXAS in SIBs. These can be attributed to three reasons: (1) Soft X-ray is of lower energy compared to hard X-rays, limiting the penetration depths that forbids signal detection. (2) It requires ultrahigh vacuum that can be hardly achieved as batteries normally involves volatile liquid electrolytes. (3) In situ/operando experimental setup is challenging to construct. The first one can be viewed as the fundamental reason that hampers the pertinent feasibility. Therefore, we will introduce the ex situsXAS studies in the following subsections.

3.2.1. Intercalation Reactions

sXAS has been widely applied to investigate cathode materials based on the intercalation mechanism. Because of its sensitivity to the surface electronic structure, sXAS can provide critical information about charge compensation and surface degradation mechanisms.

Most oxide-based cathode materials consist of multiple TM elements, with each of them performing certain functions during battery cycling. The elemental specificity of sXAS allows for pinpointing the roles of each element without interferences from other elements. For example, sXAS can be highly useful to specify the capacity contributions from distinct redox species at different voltages, which is complementary to hXAS and provides surface redox states. Layered cathodes are endowed by compositional flexibility where tuning the substituents can modulate the redox reactions and voltage profile. In O3-type NaFe0.5Ni0.5O2 and NaTi0.5Ni0.5O2, Nanba et al. obtained O K-edge and Ni L-edge in PFY mode.175 A so-called redox potential paradox was unveiled: the latter with Ni2+/Ni3+ redox pair delivers higher potential than the former relying on Ni3+/Ni4+. As shown in Figure 16a, the Ni L-edge in original NaTi0.5Ni0.5O2 displays a major peak at ∼852.8 eV, corresponding to high-spin Ni2+ that is oxidized to Ni3+ in the desodiation process. Differently, Ni L-edge of NaFe0.5Ni0.5O2 shifts toward higher energy, indicating Ni4+ formation. Here, the standard curves are theoretical calculation results of [NiO6]n− clusters based on different Ni oxidation states. The linear combination of sXAS L-edge spectra provides quantitate analysis toward charge compensation at various states of charge. After deconvolution, [NiO6]9– is divided into two portions, 37% Ni2+O52–O– and 60% ground-state Ni3+O62–.176 Besides the unambiguous clarification of reaction extent and electronic states for TM, for some SIBs electrodes, i.e., Prussian blue analogs, sXAS can shed light on the influence of coordination environments on redox reactions.177,178

Figure 16.

(a) Ni L-edge of NaTi0.5Ni0.5O2 and NaFe0.5Ni0.5O2 at different charged/discharged states in PFY mode. Linear combination was applied based on calculated patterns. Reprinted with permission from ref (175). Copyright 2016 American Chemical Society. (b) O K-edge O3-NaFeO2 at different charged/discharged states in TFY mode. C0-C7 means charging from 2.5 to 4.5 V continuously. D7-D1 is the reverse process. Adapted with permission from ref (159). (c) Mn and Ni L-edge of NaNi1/3Fe1/3Mn1/3O2 at different charged (C)/discharged (D) states. Ni was performed in total electron yield and fluorescence yield mode while Mn was under total electron yield mode. Reprinted with permission from ref (189). Copyright 2018 Wiley. (d) L-edge of Ni for Na0.78Ni0.23Mn0.69O2. Adapted with permission from ref (195).

In addition to conventional cationic redox, the anionic redox, i.e., oxygen redox, can be a major contribution at high voltage to elevate the energy density. However, materials of oxygen redox face grand challenges including O2 evolution, irreversible structural change, large voltage hysteresis, and voltage decay. sXAS can substantiate the existence of oxygen redox via O K-edge. The pre-edge intensity is normally assigned to the hybridization effect of O 2p and TM 3d orbitals, reflecting the hole state distribution and the effective charge on the oxygen atom. Among diverse anionic active cathodes, O3-NaFeO2 is a well-studied material.159,179 Exhibited in Figure 16b, pre-edge peaks are denoted as A, B, and C. Peak A becomes striking upon sodium extraction, signifying the removal of electron density from O atoms, considering that Fe L-edge is free of change at high-voltage range. More specifically, peak A is on behalf of ligand hole-that is, an electronic structure of 3d5L for Fe4+. Though the oxygen redox seemed to be highly reversible, as peak A disappeared continuously during the discharge process, the anionic activity triggered the surface Fe3O4 formation hampering sodium diffusion and thus inducing degradation. Other investigations using sXAS related to anionic redox incorporates P2-type Na0.78Co1/2Mn1/3Ni1/6O2,180−182 Na0.67[Li0.21Mn0.59Ti0.2]O2,183 Na0.72[Li0.24Mn0.76]O2,184 P3-Na0.6[Li0.2Mn0.8]O2,185 and disordered rock-salt Na1.3Nb0.3Mn0.4O2.186 These researches made similar arguments on accounts of intensity change in the pre-edge region. However, in recent years, Yang et al. proposed that the line shape, peak position, and peak intensity can all be attributed to TM characters.187 Hence, sXAS might not be a direct characterization for O anionic redox.

Taking advantage of various detection modes, the inhomogeneity of electronic structure can be discerned in the intercalation-based electrodes, facilitating insights into depth-dependent reaction dynamics.188 The fundamental interfacial chemistry for cathodes at various operating conditions can be anticipated to help design better materials. For example, Mu et al. used sXAS to uncover the surface evolution of electronic structure in O3-NaNi1/3Fe1/3Mn1/3O2 at different SOCs (Figure 16c).189 It was confirmed that Ni and Mn encountered distinct oxidation and reduction degrees from surface to subsurface. For both TEY and TFY modes, Ni is oxidized and reduced during desodiation and sodiation, respectively. The change in the TEY mode is less than that of the TFY mode, which means reduced Ni species at the surface regardless of the bulk electrochemical oxidized Ni. In contrast, in the charging process and partial discharging process (>2.9 V), the Mn valence remains +4. Interestingly, it was unambiguous that the Mn L-edge shifts toward lower energy with decreased discharge voltage (<2.9 V), symbolizing the formation of Mn2+ and Mn3+. The reduction is attributed to the surface reconstruction. After 20 cycles, the surface Mn is reduced to a lower oxidation state, partially responsible for the low Coulombic efficiency at the beginning cycles. Like O3-NaNi1/3Fe1/3Mn1/3O2, a slight reduction of Mn4+ at the surface was widely captured in many layered cathodes by TEY mode though Mn species are almost inactive in the bulk.180−182 Obviously, such surface reduction is not trivial during long-term cycling, especially for materials entirely based on Mn. sXAS clarified the fading mechanism of tunnel-type Na0.44MnO2, where increased surface Mn3+ and Mn2+ were detected.190,191 The gradient valence distribution for multiple other TM was reported, in which Ni manifests remarkable difference at distinct depths, such as Na1–xNi2/3Sb1/3O2,192 Na0.78Co1/2Mn1/3Ni1/6O2,193 and Na2/3Ni1/3Mn2/3O2.194 This unique phenomenon can also be due to the catalytic effect of high-valence TM inducing self-discharge and Na migration from the subsurface to the surface.171,174 Apart from TEY and TFY, the most surface-sensitive AEY mode can help systematically examine the gradient valence distribution, for example, in Na0.78Ni0.23Mn0.69O2 (Figure 16d).195 The valence of Ni on average is nearly +4 in the fully charged state, while a decrease in the valence from subsurface to surface to top-surface can be discerned. The problem of the Auger electron utilization is the coverage and interference of cathode–electrolyte interface (CEI). It can be also facilely replaced by another more common surface-sensitive technique, X-ray photoelectron spectroscopy (XPS). These might be the reasons that AEY is much less often employed in the sXAS compared to other modes.