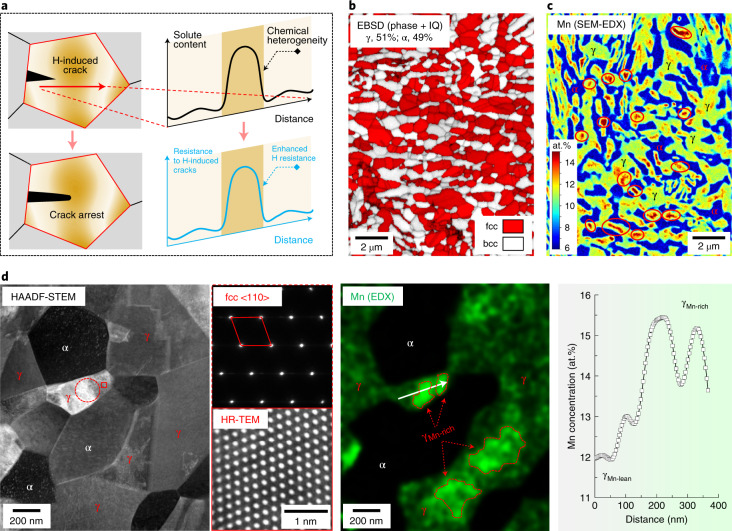

Fig. 1. Concept of chemical-heterogeneity-induced crack arresting as a measure against H embrittlement and the microstructure of a high-strength steel designed with a heterogeneous Mn distribution inside austenite.

a, Schematic image of the concept, showing a H-induced crack propagation crossing a designed solute-rich buffer region, with the solute concentration profile and the corresponding crack resistance schematically shown on the right side. b, Electron backscatter diffraction (EBSD) phase plus image quality (IQ) map showing the austenite–ferrite dual-phase microstructure. fcc, face-centred cubic; bcc, body-centred cubic. c, Scanning electron microscopy (SEM)-based energy-dispersive X-ray spectroscopy (EDX) map revealing the overall Mn distribution pattern in the microstructure. The chemical buffer zones are those regions where Mn is highly enriched (~14–16 at.% Mn) inside the austenite phase (some of them are marked by elliptical frames). d, High-angle annular dark-field scanning transmission electron microscopy (HAADF-STEM) observation with EDX analysis, showing the existence of multiple Mn-rich zones inside one austenite crystal cluster or even one austenite grain. The selected area electron diffraction and high-resolution transmission electron microscopy (HR-TEM) images taken, respectively, from the marked circular and rectangular frames are placed on the right side of the STEM image. The EDX line profile is taken from the area marked by a white arrow in the EDX map.