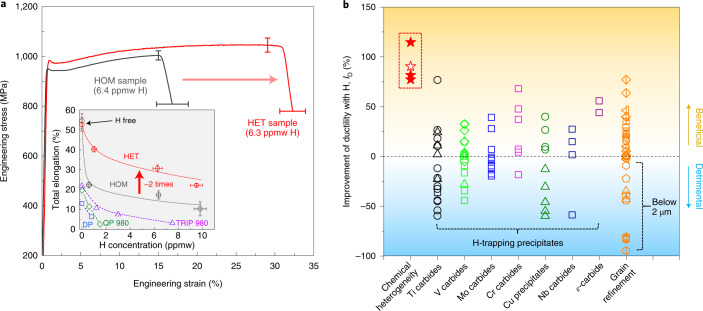

Fig. 2. Improvement of the resistance to H embrittlement via designing chemical heterogeneity.

a, Slow strain rate tensile properties of the HET sample in comparison to the HOM reference material. Both samples were subjected to the same H-precharging conditions (similar H amount). Representative tensile curves of samples with a total H concentration of ~6.5 ppmw are shown here. The inset shows the ductility of the two samples as a function of the total H concentration. The literature data of testing on commercial high-strength steels (TRIP 9808, QP 9809 and DP7 steels) with a similar strength level (that is, yield strength above ~600 MPa and tensile strength of ~1,000 MPa) are also included, indicating the required resistance to H embrittlement in automotive applications. The error bars represent standard deviations from repeated tests. b, Comparison between our approach and other H-resistance-enhancing methods reported in the literature, in terms of their effects on the improvement of the tensile ductility in the presence of H (ID = [(εf-H,after – εf-H,before)/εf-H,before ] × 100%, where εf-H,before and εf-H,after are the total elongations or fracture strains of the H-containing specimens before and after applying the resistance-enhancing approach, respectively). Our tests performed on both H-precharged specimens (solid red star symbols in red dashed box) and specimens under continuous electrochemical charging during deformation (hollow star symbol; results also shown in Supplementary Fig. 11) are shown. The literature data are from different materials including low-alloy ferritic/martensitic steels, pipeline steels, various advanced high-strength steels, maraging steels, various austenitic stainless steels and high-entropy alloys, subjected to electrochemical or gaseous H2 precharging or in-situ H charging. More details about the symbols in this figure, the values and the references are shown in Supplementary Fig. 5 and Supplementary Table 2.