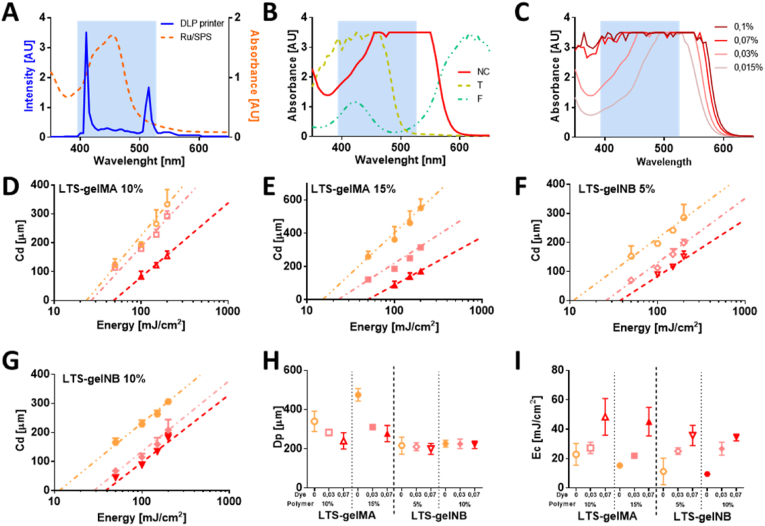

Fig. 3.

Identification of the working conditions for the DLP process suitable to ensure high resolution printing (bioresin composition and photoexposure parameters). A) Spectral matching between the light source of the DLP printer and the selected photoinitiator; B) absorption spectra of different water-soluble food dyes selected as photoabsorbers to attenuate, but not to block light transmission at 405 nm; and C) concentration-dependent spectra of a red food dye (new coccine), selected for this study. D-G) DLP working curves for selected LTS-GelMA and LTS-GelNB bioresins, showing the Cd as a function of increasing energy doses and photoabsorber concentration, showing working conditions able to achieve resolution in the z-direction <50 μm. H–I) Quantification of the sensitivity of the bioresins to different light outputs (Dp) and critical energy required to trigger the photo-induced gelation of the polymers, as a function of gelatin and photoabsorber concentrations. In the panels from D to I, data is color-coded to indicate the content of new coccine as photoabsorber following the same legend reported in panel C (pink = 0.03% dye, red = 0.07% dye), with the orange color indicating bioresins without new coccine supplementation. For the data in D) to I), n = 3 for each light dose.