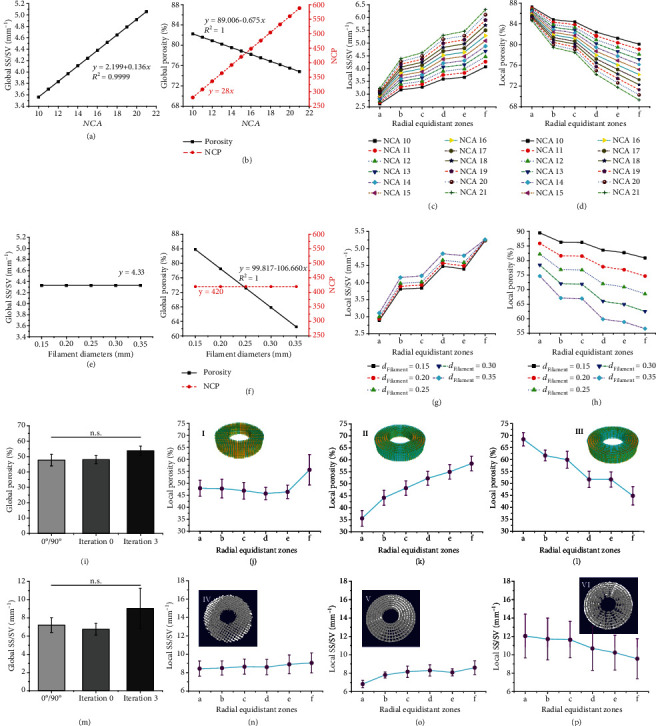

Figure 5.

Parametric characterization of the 3D printed PLGA scaffolds with functionally graded constructs. (a)-(h) Porosity and SS/SV of the global and local fractal-like scaffolds with 3 iterations controlled by NCA and DFilament. (a)-(d) Effects of the NCA on the porosity and SS/SV of the global and local fractal-like scaffolds when the same of nozzle diameter (200 μm) and three-level branching angles (α =33°, 25°, and 12°, respectively). (e)-(h) Effects of the filament (nozzle) diameters on the porosity and SS/SV of the global and local fractal-like scaffolds at the same iteration number (iteration =3), NCA =15, and three-level branching angles (α =43°, 34°, and 12°, respectively). (i)-(p) The porosity and SS/SV of the global and local scaffolds with three different graded constructs at the same porosity of ~76%. (i) The porosity of the global scaffolds. (j)-(l) The porosity of the local scaffolds with 0°/90° deposition (j) and fractal-like structures with 0 iterations (k) and 3 iterations (l). (m) The SS/SV of the global scaffolds. (n)-(p) The SS/SV of the local scaffolds with 0°/90° deposition (n) and fractal-like structures with 0 iterations (o) and 3 iterations (p). The CAD models (I-III) and 3D printed samples (IV-VI) of the scaffolds with three different gradients are represented. The designed and CT-reconstructed models are equally divided into six zones (from zone a to zone f) in the radial direction from the inner to the outer zone. Four samples (n = 4) of each type of 3D printed scaffolds are tested.