Abstract

The European Commission requested EFSA to assess if different thermal processes achieve a 5 log10 reduction in Enterococcus faecalis or Salmonella Senftenberg (775W) and (if relevant) a 3 log10 reduction in thermoresistant viruses (e.g. Parvovirus) as well as if different chemical processes achieve a 3 log10 reduction of eggs of Ascaris sp., in eight groups of Category 2 and 3 derived products and animal by‐products (ABP). These included (1) ash derived from incineration, co‐incineration and combustion; (2) glycerine derived from the production of biodiesel and renewable fuels; (3) other materials derived from the production of biodiesel and renewable fuels; (4) hides and skins; (5) wool and hair; (6) feathers and down; (7) pig bristles; and (8) horns, horn products, hooves and hoof products. Data on the presence of viral hazards and on thermal and chemical inactivation of the targeted indicator microorganisms and biological hazards under relevant processing conditions were extracted via extensive literature searches. The evidence was assessed via expert knowledge elicitation. The certainty that the required log10 reductions in the most resistant indicator microorganisms or biological hazards will be achieved for each of the eight groups of materials mentioned above by the thermal and/or chemical processes was (1) 99–100% for the two processes assessed; (2) 98–100% in Category 2 ABP, at least 90–99% in Category 3 ABP; (3) 90–99% in Category 2 ABP; at least 66–90% in Category 3 ABP; (4) 10–66% and 33–66%; (5) 1–33% and 10–50%; (6) 66–90%; (7) 33–66% and 50–95%; (8) 66–95%, respectively. Data generation on the occurrence and reduction of biological hazards by thermal and/or chemical methods in these materials and on the characterisation of the usage pathways of ABP as organic fertilisers/soil improvers is recommended.

Keywords: animal by‐products, fertilisers, compost, inactivation, Salmonella, Enterococcus, Ascaris, Parvovirus

Summary

Under the framework of Article 29 of Regulation (EC) No 178/2002, the European Commission requested EFSA to conduct an assessment of the biological risks to animal and public health deriving from the use as organic fertilisers and soil improvers (OF/SI) of the following Category 2 and 3 materials and derived products: biogas digestion residues and compost; ash derived from incineration, co‐incineration and combustion; glycerine and other products of materials derived from the production of biodiesel and renewable fuels; pet food; feed and dog chews; hides and skins; wool and hair; feather and downs; and pig bristles.

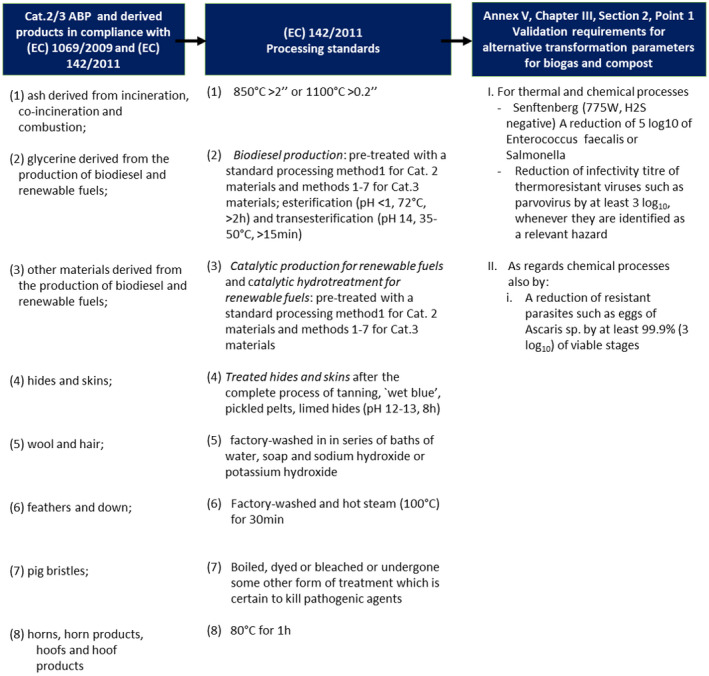

Following the clarification of the Terms of Reference (ToR), the European Commission requested EFSA to assess the requirements for alternative transformation parameters for biogas and composting plants in terms of the validation of the intended process, referred to in point 1, Section 2, Chapter III, Annex V of Commission Regulation (EU) No 142/2011, when applied to the following eight groups of Category 2 and Category 3 materials and derived products processed or obtained in accordance with Regulation (EC) No 1069/2009 and Commission Regulation (EU) No 142/2011 for the declaration of the end points in the manufacturing chain and the standard or alternative methods approved for this purpose: (1) ash derived from incineration, co‐incineration and combustion; (2) glycerine derived from the production of biodiesel and renewable fuels; (3) other materials derived from the production of biodiesel and renewable fuels; (4) hides and skins; (5) wool and hair; (6) feathers and down; (7) pig bristles; and (8) horns, horn products, hooves and hoof products.

Point 1 of Section 2 of Chapter III of Annex V of Commission Regulation (EU) No 142/2011 states that the validation of the intended process must demonstrate that the process achieves the following overall risk reduction: for thermal and chemical processes, a reduction of 5 log10 of Enterococcus faecalis or Salmonella Senftenberg (775W, H2S negative), and a reduction in the infectivity titre of thermoresistant viruses such as parvovirus by at least 3 log10, whenever they are identified as a relevant hazard; and as regards chemical processes also a reduction of resistant parasites such as eggs of Ascaris sp. by at least 99.9% (3 log10) of viable stages.

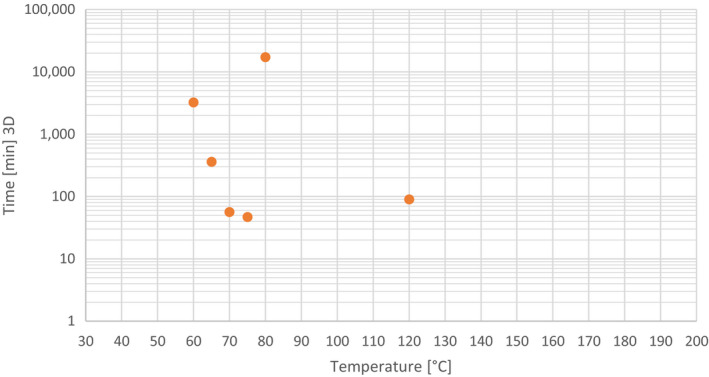

The parameters of the processes were extracted from Annex III, Annex IV and Annex XIII of Commission Regulation (EU) No 142/2011. In the materials for which processing time was not clearly stated in the legislation (group 5 – wool and hair, and group 7 – pig bristles), two plausible scenarios were explored: 5 min and 60 min (covered in assessment question 1 (AQ1) (see Protocol in Annex A). An extensive literature search was conducted to identify viral hazards for humans and animals that have been isolated in the eight groups of materials included in the mandate. Hazards intrinsically present in the matrix were considered, while hazards deriving from external sources or cross‐contamination were excluded from the hazard identification (AQ3). Parvoviridae were considered, as a worse‐case scenario, when no intrinsic viral hazards were identified. Extensive literature searches were conducted to extract data from the scientific literature about thermal and/or chemical inactivation of E. faecalis, S. Senftenberg (AQ2), the selected viruses (non‐enveloped viruses) (AQ4) and eggs of Ascaris sp. (AQ5)

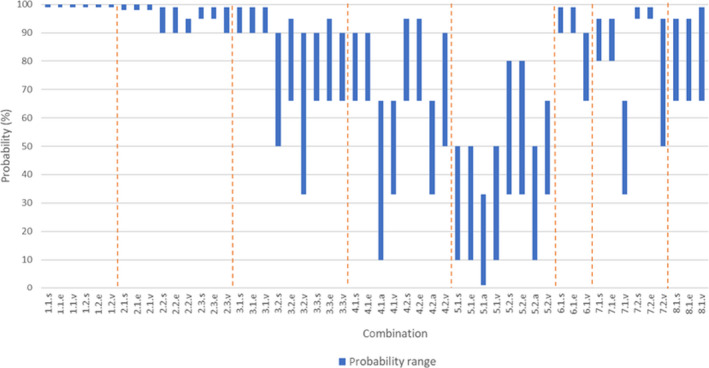

For each of the assessment questions (AQ), a body of evidence was built by summarising the data extracted from the literature on thermal and chemical inactivation of the indicator microorganisms and biological hazards for each of the materials and derived products listed in the ToR, and the existing uncertainties. Using this body of evidence, an expert knowledge elicitation procedure was performed involving eight experts (six Working Group members and two EFSA staff) who answered the following questions: (a) What is the probability that a 5 log10 reduction of E. faecalis is achieved in more than 99% of cases, by application of the relevant process/es, assuming that the process/es is/are performed as prescribed and that the indicated process conditions are achieved? (b) What is the probability that a 5 log10 reduction of S. Senftenberg (775 W, H2S negative) is achieved in more than 99% of cases, by application of the relevant process/es, assuming that the process/es is/are performed as prescribed and that the indicated process conditions are achieved? (c) What is the probability that a 3 log10 reduction of Parvovirus or the identified most resistant viruses is achieved in more than 99% of cases, by application of the relevant process/es, assuming that the process/es is/are performed as prescribed and that the indicated process conditions are achieved? (d) What is the probability that a 3 log10 reduction of eggs of Ascaris sp. is achieved in more than 99% of the cases, by application of the relevant chemical process/es, assuming that the process/es is/are performed as prescribed and that the indicated process conditions are achieved?

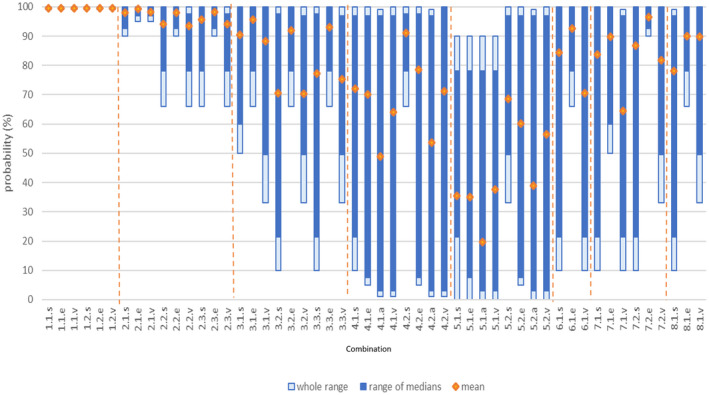

To answer these questions, first, subjective probability ranges were provided by each of the individual experts for the 52 different combinations of materials and derived products, processes and indicator microorganisms and biological hazards. Second, after an open discussion, a single consensus probability range was obtained for each combination, based on the estimates provided by the individual experts. These consensus probability ranges are considered to best represent the uncertainty on whether the indicated log10 reductions are achieved by the standard processes for the different materials. The probability ranges for the most resistant indicator microorganisms and biological hazards were selected as the worst‐case scenario to describe the uncertainty around the overall efficacy of the standard or alternative transformation processes for animal by‐products (ABP) declaration of end points or placement in the market, defined by time/temperature/pH parameters.

The certainty that, at least in 99% of cases, the transformation processes as defined in the legislation, or in the scenarios agreed by the Working Group, are able to reduce the indicator microorganisms and biological hazards to the required extent, was judged to be as follows:

Ash derived from incineration, co‐incineration and combustion: 99–100% for both 850°C, > 2 s and 1,100°C, > 0.2 s (E. faecalis, S. Senftenberg and Parvoviridae);

Glycerine derived from the production of biodiesel and renewable fuels: 98–100% for Category 2 material subjected to Method 1 at 133°C, 20 min, 3 bar, followed by esterification and transesterification (E. faecalis, S. Senftenberg and Parvoviridae); 90–95% and 90–99% for Category 3 material subjected to 80°C for 120 min and 100°C for 60 min, followed by transesterification, respectively (Parvoviridae). Since method 5 must ensure that the two time–temperature combinations are met, even if they were assessed separately, for Category 3 material it is considered at least 90–99% certain that the transformation process is able to reduce, to the required extent, Parvoviridae, the most resistant of the three indicator microorganisms (E. faecalis, S. Senftenberg and Parvoviridae).

Other materials derived from the production of biodiesel and renewable fuels: 90–99% for Category 2 material subjected to Method 1 at 133°C, 20 min, 3 bar (E. faecalis, S. Senftenberg and Parvoviridae); and 33–90% and 66–90% for Category 3 material subjected to 80°C for 120 min and 100°C for 60 min, respectively (Parvoviridae). Since method 5 must ensure that the two time–temperature combinations are met, even if they were assessed separately, for Category 3 material, it is considered at least 66–90% certain that the transformation process is able to reduce, to the required extent, Parvoviridae, the most resistant of the three indicator microorganisms (E. faecalis, S. Senftenberg and Parvoviridae).

Hides and skins: 10–66% and 33–66% for pH 12–13 for 8 h, and pH 12 for > 8 h followed by pH < 3 for 16 h, respectively (eggs of Ascaris sp.);

Wool and hair: 1–33% and 10–50% for pH > 12–13, applied for 5 or 60 min, respectively (eggs of Ascaris sp.);

Feathers and down: 66–90% for 100°C for at least 30 min (Anelloviridae and Circoviridae);

Pig bristles: 33–66% and 50–95% for 100°C, applied for 5 or 60 min, respectively (Parvoviridae);

Horns, horn products, hooves and hoof products: 66–95% for 80°C for 60 min (E. faecalis and S. Senftenberg).

In order to reduce the uncertainty of the assessment, it is recommended to generate data on the occurrence of biological hazards, the intrinsic physico‐chemical properties (e.g. pH, water activity (aw)), and on the thermal and non‐thermal (chemical) inactivation of the indicator microorganisms in ABP matrices.

1. Introduction

1.1. Background and Terms of Reference as provided by the requestor

Derived products referred to in Article 3(2) of Regulation (EC) No 1069/20091 that have reached the end point in the manufacturing chain of animal by‐products may subsequently be placed on the market without restrictions under this Regulation and shall no longer be subject to official controls in accordance with Regulation (EC) No 1069/2009 and Regulation (EU) 2017/6252.

Article 32 of Regulation (EC) No 1069/2009 provides rules for placing on the market and use of organic fertilisers and soil improvers (OF/SI) of Category 2 and 3 materials. By the exclusion of Category 1 material from the production of OF/SI certain risks to animal and public health and to the environment are already addressed. However, for the use of those animal by‐products, which are classified as Category 2 material referred to in Article 9(c), a specific risk assessment is necessary to ensure that the use of such animal by‐products as organic fertiliser does not entail a risk to animal and public health and to the environment.

Regulation (EU) 2019/10093 establishing rules for the placing on the market of EU fertilising products, introduced in Article 5(2) of Regulation (EC) No 1069/2009 a reference to Article 32 of that Regulation, and thus the possibility to determine the end point in the manufacturing chain of OF/SI.4

Derived products of Category 2 and Category 3 materials,5 referred to respectively in Articles 9 and 10 of Regulation (EC) No 1069/2009, may be placed on the market and used as OF/SI. Those materials present comparable TSE/BSE risks since none of them includes specific risk materials as defined in Article 3(1)(g) of Regulation (EC) No 999/20016.

The European Parliament and the Council asked the Commission to initiate an assessment of derived products referred to in Article 32 that are already widely used in the Union as OF/SI.

This assessment shall cover at least the following products:

meat meal, bone meal, meat‐and-bone meal, hydrolysed proteins of Category 3 materials,

processed manure, compost, biogas digestion residues, feather meal, glycerine and other products of Category 2 or 3 materials derived from the production of biodiesel and renewable fuels,

pet food, feed and dog chews that have been refused for commercial reasons or technical failures,

derived products from blood of animals, hides and skins, hoofs and horns, guano of bats and birds, wool and hair, feather and downs, and pig bristles.

The following derived products are widely placed on the market for use as OF/SI:

-

1

Biogas digestion residues and compost referred to in the second subparagraph of Article 32(1) of Regulation (EC) No. 1069/2009. Standard transformation parameters for compost and biogas transformation residues are laid down in Section 1 of Chapter III of Annex V to Regulation (EU) No 142/20117. With reference to point 2(a) of Section 1 and point 2(b) of Section 2 of Chapter II of the aforementioned Annex V, Category 2 materials intended for compost or biogas transformation should be processed in accordance with processing method 1. Biogas and compost transformation has been subject to several EFSA assessments in 20058; 20099 and 201510

-

2

Ash derived from incineration, co‐incineration and combustion, carried out in accordance with methods laid down in Annex III to Regulation (EU) No 142/2011, of Category 2 and 3 materials and derived products may be used as fertilising products. The disposal of animal by‐products, including meat‐and-bone meal, by incineration, co‐incineration and combustion has been subject to EFSA assessment on several occasions. The following scientific opinions led to the conclusion that direct incineration of carcasses and incineration or burning under appropriate controlled condition of rendered material are economically feasible technologies for safe disposal of TSE risk material:

Overview of the BSE risk assessments of the European Commission's Scientific Steering Committee (SSC) and its TSE/BSE ad hoc Group11;

Opinion on open burning of potentially TSE‐infected animal materials adopted by the Scientific Steering Committee at its meeting of 16‐17 January 200312;

Opinion on the use of small incinerators for BSE risk reduction by the Scientific Steering Committee meeting of 16‐17 January 200313; and

Opinion of the Scientific Panel on Biological Hazards of the European Food Safety Authority on the “Quantitative risk assessment of the animal BSE risk posed by meat and bone meal with respect to the residual BSE risk”.14

Based on those scientific opinions, standards for the disposal of animal by‐products as waste by incineration, the disposal or recovery by co‐incineration and the use as a fuel for combustion have been laid down in Regulation (EU) No 142/201115.

-

3

Article 3 of Regulation (EU) No 142/2011 sets out end points for certain Category 2 and 3 materials which may be used in the manufacturing of OF/SI, such as derived products referred to in points (b) to (h) or side product of biofuel and oleochemical production referred to in points (a), (i), (j) and (k) of that Article.

Certain end points have been determined based on EFSA assessments of 2004,16 2010,17 201118 and 2015.19

1.1.1.

Terms of Reference

In the light of the above, and in accordance with Article 29 of Regulation (EC) No 178/200220, the Commission requests EFSA to provide a scientific opinion concerning the capacity of certain specific processing or transformation methods used in the production of organic fertilisers and soil improvers (OF/SI) in view of determining the endpoints in the manufacturing chain of CE‐marked EU fertilising products.

In particular, the scientific opinion should comprise an assessment of the biological risks to animal and public health deriving from the use as OF/SI of the following Category 2 and 3 materials and derived products processed in accordance with Regulation (EC) No 1069/2009 and Regulation (EU) No 142/2011:

biogas digestion residues and compost;

ash derived from incineration, co‐incineration and combustion;

glycerine and other products of materials derived from the production of biodiesel and renewable fuels;

pet food;

feed and dog chews;

hides and skins;

wool and hair;

feather and downs;

and pig bristles.

1.2. Interpretation of the Terms of Reference

As a result of discussions conducted with the requestor, on 25 January 2021, the European Commission indicated to EFSA that the Terms of Reference (ToR) are clarified as follows:

‘EFSA is requested to assess the requirements for alternative transformation parameters for biogas and composting plants in terms of the validation of the intended process, referred to in point 1 of Section 2 of Chapter III of Annex V to Regulation (EU) No 142/2011, when applied to other derived products. In particular, the scientific opinion should comprise an assessment of the following Category 2 and 3 materials and derived products processed or obtained in accordance with Regulation (EC) No 1069/2009 and Regulation (EU) No 142/2011 for the declaration of the end points in the manufacturing chain and the standard or alternative methods approved for this purpose:

ash derived from incineration, co‐incineration and combustion;

glycerine derived from the production of biodiesel and renewable fuels;

other materials derived from the production of biodiesel and renewable fuels;

hides and skins;

wool and hair;

feather and downs;

pig bristles;

horns, horn products, hoofs and hoof products.’

The requestor clarified that only the transformation processes included in Commission Regulation (EU) 142/2011 for the declaration of the end points in the manufacturing chain (for raw materials) and the approved standard or alternative methods to produce derived products should be considered, disregarding the further transformation processes, the fertiliser industry might apply to produce the final OF/SI, and without considering the use or applications of the final OF/SI product. It was also confirmed that only materials produced in the EU should be considered, as all imported materials from non‐EU countries will have to comply with the EU legislation. The requestor also provided an updated list of Category 2 and 3 animal by‐products (ABP) and derived materials that should be included in the assessment.

Based on this clarification, biogas digestion residues (digestate) and compost, pet food, feed and dog chews, initially included in the ToR, were excluded from the assessment. A new ABP group, horns, horn products, hooves and hoof products, was added.

Thus, it was requested to assess for the list of materials included in the ToR if: (i) the transformation processes for the declaration of the end points in the manufacturing chain or (ii) the standard or alternative methods for the production of ABP derived products meet the requirements for alternative transformation parameters for biogas and composting plants in terms of the validation of the intended process, referred to in point 1 of Section 2 of Chapter III of Annex V to Regulation (EU) No 142/2011.

It is important to emphasise that, as a result of the new request from the European Commission, the output of the scientific opinion was not a full risk assessment, but consisted of the estimation of the level of inactivation/reduction of concentration of biological hazards and indicator microorganisms of interest after the processing methods and standard or alternative methods are applied. Thus, the output of the assessment did not conclude on any relationship between the presence of hazards and the risks to human or animal health of the OF/SI containing them. Moreover, the output of this scientific opinion comprises an evaluation of certain processes applied to produce or transform a list of materials that can be further processed, in the form of composting or any other method, and used as an OF/SI.

As some of the materials in the list of the ToR include multiple substrates/matrices, it was agreed to use throughout the opinion the term ‘group’ followed by a number in the order of the ToR for each of the eight items included in it, as follows: group 1: ash derived from incineration, co‐incineration and combustion; group 2: glycerine derived from the production of biodiesel and renewable fuels; group 3: other materials derived from the production of biodiesel and renewable fuels; group 4: hides and skins; group 5: wool and hair; group 6: feathers and down; group 7: pig bristles; and group 8: horns, horn products, hooves and hoof products.

The materials in the groups included in the mandate are of two very different natures: some of them are residues or derived materials produced during the treatment of raw ABP with approved standard or alternative methods (Groups 1, 2, 3); and others are raw ABP (Groups 4, 5, 6, 7 and 8). In the former, the parameters of the standard or alternative methods will be applied, whereas in the latter, the parameters of the treatments required for the declaration of end points (Groups 4, 5 and 6) or the treatments for movement of the material between regions (Group 7) or for the placing on the market (Group 8) will be assessed. These differences will have an impact on the hazard identification conducted for each type of materials (see Section 3).

1.2.1. Background legislation and approach to answer the ToR

Commission Regulation (EU) No 142/2011, in Section 1, Chapter III, Annex V, details the minimum requirements of Category 3 ABP to be used as raw materials in a biogas or compost plant, as follows:

maximum particle size before entering the unit or the composting reactor: 12 mm;

minimum temperature in all material in the unit or in the reactor: 70°C; and

minimum time in the unit without interruption: 60 min.

Section 2.1 of the same Chapter describes the alternative transformation parameters for biogas and composting plants. According to it, the competent authority may authorise the use of parameters other than the parameters set out in point 1 of Section 1 of Chapter I and other than the standard transformation parameters, provided that the method is demonstrated to be at least as safe as the standard method. That demonstration shall include a validation, which shall be carried out in accordance with the following requirements:

-

a

Identification and analysis of possible hazards, including the impact of input material, based on a full description of the transformation conditions and parameters;

-

b

A risk assessment, which evaluates how the specific transformation conditions referred to in point (a) are achieved in practice under normal and atypical situations;

-

c

Validation of the intended process by measuring the reduction of viability/infectivity of:

-

endogenous indicator organisms during the process, where the indicator is:

-

—

consistently present in the raw material in high numbers,

-

—

not less heat resistant to the lethal aspects of the transformation process, but also not significantly more resistant than the pathogens for which it is being used to monitor,

-

—

relatively easy to quantify and to identify and to confirm; or

-

—

a well‐characterised test organism or virus, during exposure, introduced in a suitable test body into the starting material.

-

d

The validation of the intended process referred to in point (c) must demonstrate that the process achieves the following overall risk reduction:

-

i

for thermal and chemical processes by:

-

—

a reduction of 5 log 10 of Enterococcus faecalis or Salmonella Senftenberg (775W, H 2 S negative),

-

—

reduction of infectivity titre of thermoresistant viruses such as parvovirus by at least 3 log 10 , whenever they are identified as a relevant hazard; and

-

—

-

ii

as regards chemical processes also by:

-

—

a reduction of resistant parasites such as eggs of Ascaris sp. by at least 99,9% (3 log 10 ) of viable stages;

-

—

-

e)

Designing a complete control programme including procedures for monitoring the functioning of the process referred to in point (c);

-

f)

Measures ensuring continuous monitoring and supervision of the relevant process parameters fixed in the control programme when operating the plant.

-

i

Details on the relevant process parameters used in a biogas or composting plant as well as other critical control points must be recorded and maintained so that the owner, operator or their representative and the competent authority can monitor the operation of the plant.

Records must be made available by the operator to the competent authority on request. Information relating to a process authorised under this point must be made available to the Commission on request.

Taking into account the content of this EU Regulation, an assessment was undertaken to determine if the processing standards for the declaration of the end points in the manufacturing chain or the standard or alternative methods approved for the production of derived products from the ABP in the list of materials mentioned in Section 1.2 achieve: (i) a reduction of 5 log10 of Enterococcus faecalis or Salmonella Senftenberg (775W, H2S negative) and a reduction of infectivity titre by at least 3 log10 of those thermoresistant viruses that are identified as a relevant hazard, and, in the case of chemical processes, also a reduction of eggs of Ascaris sp. by 3 log10. This was achieved by addressing the following assessment questions (AQ):

AQ1: What are the technical parameters of the transformation processes for the declaration of the end points in the manufacturing chain, and the standard or alternative methods approved to produce derived materials or residues as described in the legislation (Commission Regulation (EU) 142/2011) of the Category 2 and 3 materials and derived products as defined in the mandate?

AQ2: Is the 5 log10 reduction of the indicator microorganisms Enterococcus faecalis (EF) or Salmonella Senftenberg (SS) achieved for each of the Category 2 and 3 materials and derived products, as defined in the clarification of the mandate, by the technical parameters identified in AQ1?

AQ3: Which viral hazards can be intrinsically found in the Category 2 and 3 materials and derived products as defined in the clarification of the mandate?

AQ4: Is the 3 log10 reduction of the selected thermoresistant viruses identified in AQ3 achieved for each of the Category 2 and 3 materials and derived products, as defined in the clarification of the mandate, by the technical parameters identified in AQ1?

AQ5: Is the 3 log10 reduction of eggs of Ascaris sp. achieved for each of the Category 2 and 3 materials and derived products, as defined in the clarification of the mandate, by the technical parameters identified in AQ1 for the processes based on chemical treatments (group 4 – hides and skins; group 5 – wool and hair)?

2. Data and methodologies

2.1. Parameters of the transformation processes (AQ1)

Two methods were applied to ascertain technical parameters of the transformation processes for the declaration of the end points in the manufacturing chain, and the standard or alternative methods as described in the legislation for the groups of materials defined in the mandate:

For materials for which details of the technical parameters of the transformation processes are explicit in the legislation: Annexes III, IV and XIII of Commission Regulation (EU) No 142/2011 were reviewed.

For materials for which details of the technical parameters of the transformation processes are not explicit in the legislation: two plausible scenarios (5 min and 60 min) were assessed.

In cases where the technical parameters were explicitly defined in the legislation, they were used as reference parameters for the assessment. When they were not explicitly defined, the uncertainty associated with the interpretation of the legislation was taken into account and described. The selected technical parameters are presented in Section 3 and applied in the expert knowledge elicitation (EKE) by producing 52 combinations of processes, materials and hazards.

2.2. Viral hazards identification (AQ3)

To identify viral hazards for humans and animals that can be found intrinsically in the Category 2 and 3 materials and derived products as defined in the list of materials provided in the clarification of the mandate, an extensive literature search was conducted. The selection of studies was based on experimental or observational studies in which the viral species, genus or family are mentioned in relation to the materials included in the mandate (raw materials). The database used was Scopus, Elsevier (English language, worldwide and not restricted in years). The search strings were designed by combining the biological hazards (virus), the matrix (material as in the mandate) and ABP. The latter group of terms was added to reduce the number of false‐positive hits. The search strings are displayed in Table A.2 in Annex A. A table with the identified viral hazards was produced with the following fields: material (Category 2 and 3 material or derived product), characteristics (non‐enveloped, DNA/RNA), family of the viral hazard, viral hazard, (main) species affected and reference/s (see Table 4 in Section 3.5).

Table A.2.

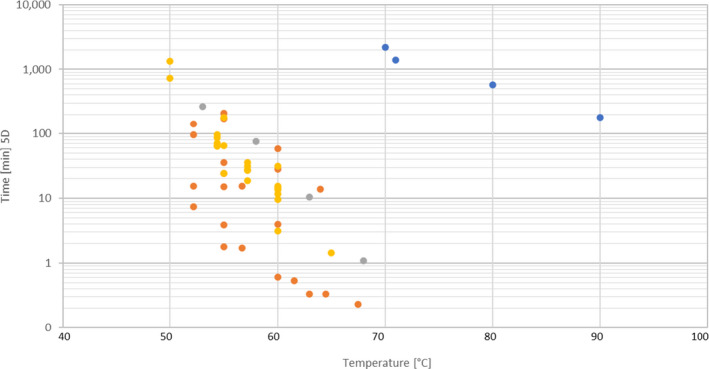

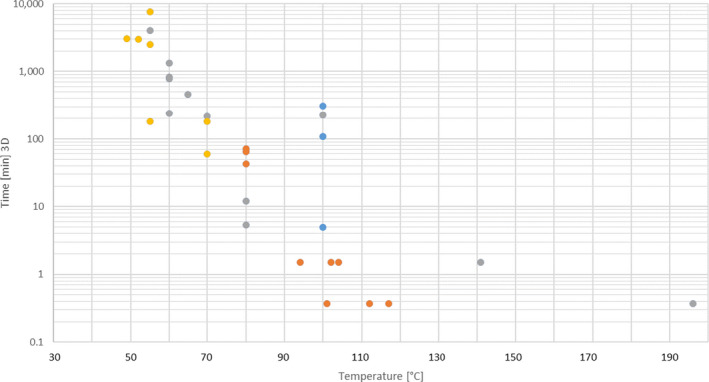

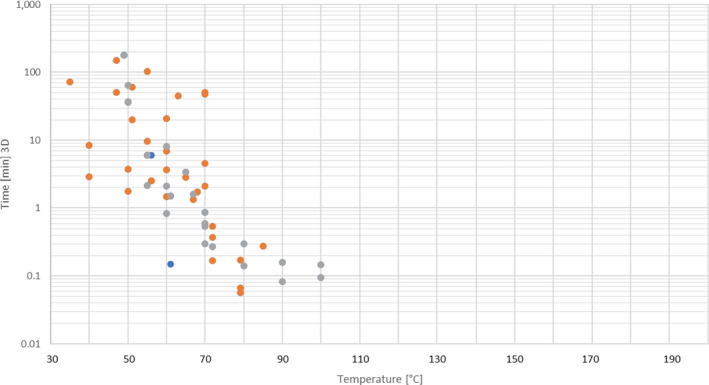

Details of the data points used to produce Figure 5 from the references identified in the literature review for Salmonella Senftenberg

| Hazard | Product group | Product/or medium | Treatment | pH | T (°C) | D (min) | 5D (min) | Ref |

|---|---|---|---|---|---|---|---|---|

| Salmonella ser. Senftenberg 775W | Liquid food product | Liquid whole eggs | Heat | 55 | 34.3 | 171.5 | Doyle and Mazzotta (2000) | |

| Salmonella ser. Senftenberg 775W | Liquid food product | Liquid whole eggs | Heat | 60 | 5.6 | 28 | ||

| Salmonella ser. Senftenberg 775W | Liquid food product | Liquid whole eggs | Heat | 64 | 2.8 | 14 | ||

| Salmonella ser. Senftenberg 775W | Liquid food product | Liquid egg yolks | Heat | 55 | 42 | 210 | ||

| Salmonella ser. Senftenberg 775W | Liquid food product | Liquid egg yolks | Heat | 60 | 11.8 | 59 | ||

| Salmonella ser. Senftenberg 775W | Liquid food product | Liquid egg whites | Heat | 55 | 3 | 15 | ||

| Salmonella ser. Senftenberg 775W | Liquid food product | Liquid egg whites | Heat | 60 | 0.8 | 4 | ||

| Salmonella ser. Senftenberg 775W | Liquid food product | Raw milk | Heat | 60 | 0.122 | 0.61 | ||

| Salmonella ser. Senftenberg 775W | Liquid food product | Raw milk | Heat | 61.5 | 0.107 | 0.535 | ||

| Salmonella ser. Senftenberg 775W | Liquid food product | Raw milk | Heat | 63 | 0.067 | 0.335 | ||

| Salmonella ser. Senftenberg 775W | Liquid food product | Raw milk | Heat | 64.5 | 0.067 | 0.335 | ||

| Salmonella ser. Senftenberg 775W | Liquid food product | Raw milk | Heat | 67.5 | 0.046 | 0.23 | ||

| Salmonella ser. Senftenberg | Solid food product | Ground beef | Heat | 53 | 53 | 265 | ||

| Salmonella ser. Senftenberg | Solid food product | Ground beef | Heat | 58 | 15.2 | 76 | ||

| Salmonella ser. Senftenberg | Solid food product | Ground beef | Heat | 63 | 2.08 | 10.4 | ||

| Salmonella ser. Senftenberg | Solid food product | Ground beef | Heat | 68 | 0.22 | 1.1 | ||

| Salmonella ser. Senftenberg | Liquid culture medium | PO4 | Heat | 55 | 13 | 65 | ||

| Salmonella ser. Senftenberg | Liquid culture medium | PO4 | Heat | 65 | 0.29 | 1.45 | ||

| Salmonella ser. Senftenberg | Liquid culture medium | PO4 | Heat | 54.4 | 14.23 | 71.15 | ||

| Salmonella ser. Senftenberg | Liquid culture medium | PO4 | Heat | 57.2 | 6.23 | 31.15 | ||

| Salmonella ser. Senftenberg | Liquid culture medium | PO4 | Heat | 60 | 2.69 | 13.45 | ||

| Salmonella ser. Senftenberg S2 | Liquid culture medium | PO4 | Heat | 54.4 | 17.13 | 85.65 | ||

| Salmonella ser. Senftenberg S2 | Liquid culture medium | PO4 | Heat | 57.2 | 7.14 | 35.7 | ||

| Salmonella ser. Senftenberg S2 | Liquid culture medium | PO4 | Heat | 60 | 2.88 | 14.4 | ||

| Salmonella ser. Senftenberg R1 | Liquid culture medium | PO4 | Heat | 54.4 | 19.32 | 96.6 | ||

| Salmonella ser. Senftenberg R1 | Liquid culture medium | PO4 | Heat | 57.2 | 3.72 | 18.6 | ||

| Salmonella ser. Senftenberg R1 | Liquid culture medium | PO4 | Heat | 60 | 3.06 | 15.3 | ||

| Salmonella ser. Senftenberg R2 | Liquid culture medium | PO4 | Heat | 54.4 | 12.77 | 63.85 | ||

| Salmonella ser. Senftenberg R2 | Liquid culture medium | PO4 | Heat | 57.2 | 5.39 | 26.95 | ||

| Salmonella ser. Senftenberg R2 | Liquid culture medium | PO4 | Heat | 60 | 2.31 | 11.55 | ||

| Salmonella ser. Senftenberg R6 | Liquid culture medium | PO4 | Heat | 54.4 | 13.14 | 65.7 | ||

| Salmonella ser. Senftenberg R6 | Liquid culture medium | PO4 | Heat | 57.2 | 5.56 | 27.8 | ||

| Salmonella ser. Senftenberg R6 | Liquid culture medium | PO4 | Heat | 60 | 1.92 | 9.6 | ||

| Salmonella ser. Senftenberg | Liquid culture medium | HI | Heat | 50 | 268 | 1340 | ||

| Salmonella ser. Senftenberg | Liquid culture medium | HI | Heat | 55 | 36.2 | 181 | ||

| Salmonella ser. Senftenberg | Liquid culture medium | HI | Heat | 60 | 6.3 | 31.5 | ||

| Salmonella ser. Senftenberg | Liquid culture medium | HI | Heat | 50 | 146 | 730 | ||

| Salmonella ser. Senftenberg | Liquid culture medium | HI | Heat | 55 | 4.9 | 24.5 | ||

| Salmonella ser. Senftenberg | Liquid culture medium | HI | Heat | 60 | 0.62 | 3.1 | ||

| Salmonella ser. Senftenberg 775W | Liquid food product | Liquid egg whites | Heat | 9 | 52.2 | 28.6 | 143 | |

| Salmonella ser. Senftenberg 775W | Liquid food product | Liquid egg whites | Heat | 9 | 55 | 7.2 | 36 | |

| Salmonella ser. Senftenberg 775W | Liquid food product | Liquid egg whites | Heat | 9 | 56.7 | 3.1 | 15.5 | |

| Salmonella ser. Senftenberg 775W | Liquid food product | Liquid egg whites | Heat | 9 | 52.2 | 3.1 | 15.5 | |

| Salmonella ser. Senftenberg 775W | Liquid food product | Liquid egg whites | Heat | 9 | 55 | 0.78 | 3.9 | |

| Salmonella ser. Senftenberg 775W | Liquid food product | Liquid egg whites | Heat | 9.5 | 52.2 | 19.3 | 96.5 | |

| Salmonella ser. Senftenberg 775W | Liquid food product | Liquid egg whites | Heat | 9.5 | 55 | 4.9 | 24.5 | |

| Salmonella ser. Senftenberg 775W | Liquid food product | Liquid egg whites | Heat | 9.5 | 56.7 | 0.34 | 1.7 | |

| Salmonella ser. Senftenberg 775W | Liquid food product | Liquid egg whites | Heat | 9.5 | 52.2 | 1.47 | 7.35 | |

| Salmonella ser. Senftenberg 775W | Liquid food product | Liquid egg whites | Heat | 9.5 | 55 | 0.36 | 1.8 | |

| Salmonella ser. Senftenberg 775W | Semi‐liquid food product | Chocolate | Heat | 70 | 440 | 2200 | ||

| Salmonella ser. Senftenberg 775W | Semi‐liquid food product | Chocolate | Heat | 71 | 276 | 1380 | ||

| Salmonella ser. Senftenberg 775W | Semi‐liquid food product | Chocolate | Heat | 80 | 116 | 580 | ||

| Salmonella ser. Senftenberg 775W | Semi‐liquid food product | Chocolate | Heat | 90 | 36 | 180 |

Table 4.

Identified intrinsic viral hazards in the ELS

| Material | Characteristics | Family | Viral hazard | Species reported to be affected | Reference from the viral hazard identification |

|---|---|---|---|---|---|

| Hides and skins | Enveloped DNA | Poxviridae | Orthopoxvirus | Cattle | Damaso et al. (2000) |

| Enveloped DNA | Poxviridae | Camelpox virus | Camelids | Otterbein et al. (1996), Balamurugan et al. (2013) | |

| Enveloped DNA | Poxviridae | Cutaneous avian poxvirus | Poultry | Ferreira et al. (2018) | |

| Enveloped DNA | Alloherpesviridae | Koi herpesvirus | Fish | Pokorova et al. (2005) | |

| Enveloped DNA | Poxviridae | Lumpy skin disease virus | Cattle, water buffalo | Biosecurity New Zealand (2007), Davies (1991), Carn (1993), Tuppurainen and Oura (2012), Tuppurainen et al. (2017), Abutarbush et al. (2016), Gelaye and Lamien (2019) | |

| Enveloped DNA | Herpesviridae | Marek's disease virus | Chicken | Jarosinski et al. (2007) | |

| Enveloped DNA | Poxviridae | Myxoma virus | Rabbit | Meredith (2013) | |

| Enveloped DNA | Poxviridae | Orf virus (Parapoxvirus) | Sheep, goats | Huerter et al. (1991), Haig and Mercer (1998), Haig and McInnes (2002), Lateef et al. (2010), Nandi et al. (2011), Fleming et al. (2015) | |

| Enveloped DNA | Poxviridae | Parapoxvirus | Deer | Ueda et al. (2007) | |

| Enveloped DNA | Poxviridae | Sheep poxvirus and Goat poxvirus | Sheep, goats | Biosecurity New Zealand (2007), Carn (1993), Babiuk et al. (2008), Tuppurainen et al. (2017) | |

| Enveloped RNA | Flaviviridae | Bovine viral diarrhoea virus (type 2)* | Cattle, sheep, pigs | Biosecurity New Zealand (2007), Grooms and Keilen (2002), Brodersen (2004), Babiuk et al. (2008) | |

| Enveloped RNA | Flaviviridae | Classical swine fever virus* | Pigs | Kaden et al. (2007) | |

| Enveloped RNA | Amnoonviridae | Tilapia lake virus | Fish | Behera et al. (2018) | |

| Non‐enveloped DNA | Papillomaviridae | Bovine papillomavirus | Equines, cattle | Borzacchiello et al. (2008), Taylor and Haldorson (2013), Trewby et al. (2014), Bocaneti et al. (2016) | |

| Non‐enveloped DNA | Papillomaviridae | Cottontail rabbit papillomavirus | Rabbit | Han et al. (1998) | |

| Non‐enveloped RNA | Reoviridae | Bluetongue virus | Sheep, cattle | MacLachlan et al. (2009) | |

| Non‐enveloped RNA | Picornaviridae | Foot and mouth disease virus* | Cloven‐hoofed animals | Biosecurity New Zealand (2007), Nfon et al. (2008) | |

| Non‐enveloped RNA | Picornaviridae | Swine vesicular disease virus | Pigs | Biosecurity New Zealand (2007) | |

| Wool and hair | Enveloped DNA | Poxviridae | Sheep and Goat poxviruses | Sheep, goats, Cattle | Zhou et al. (2012), Gale et al. (2016) |

| Enveloped RNA | Flaviviridae | Bovine viral diarrhoea* virus | Cattle | Singh et al. (2011), Callan et al. (2002) | |

| Non‐enveloped RNA | Picornaviridae | Foot and mouth disease* virus | Sheep | McColl et al. (1995) | |

| Non‐enveloped DNA | Parvoviridae | Ungulate tetraparvovirus | Mule deer | Li et al. (2016) | |

| Enveloped DNA | Poxviridae | Orf virus (Parapoxvirus) | Sheep | Fleming et al. (2017) | |

| Enveloped RNA | Flaviviridae | Border disease virus (BDV) | Sheep | Kalaiyarasu et al. (2019) | |

| Feathers and down | Non‐enveloped DNA | Anelloviridae | Chicken anaemia virus | Poultry | Todd (2000), Davidson and Skoda (2005), Hernandez‐Divers et al. (2006) |

| Non‐enveloped DNA | Circoviridae | Duck circovirus | Duck | Liu et al. (2020) | |

| Enveloped RNA | Orthomyxoviridae | Avian influenza virus* | Poultry | Kaleta and Hönicke (2004), Hafez (2005), Dudley (2008), Beato et al. (2009), Yamamoto et al. (2010, 2017), Huchzermeyer (1997) | |

| Enveloped RNA | Paramyxoviridae | Newcastle disease virus* | Poultry | Hafez (2005), Huchzermeyer (1997), Hernandez‐Divers et al. (2006) | |

| Enveloped DNA | Herpesviridae | Marek′s disease virus | Poultry | Couteaudier and Denesvre (2014), Couteaudier et al. (2016), Zhang et al. (2015), Davidson et al. (2005); Denesvre (2013) | |

| Enveloped DNA | Poxviridae | Fowlpox virus | Poultry | Davidson and Skoda (2005) | |

| Enveloped RNA | Retroviridae | Reticuloendotheliosis virus | Poultry | Davidson and Skoda (2005) | |

| Enveloped RNA | Retroviridae | Avian leucosis virus | Poultry | Davidson and Skoda (2005) | |

| Enveloped RNA | Flaviviridae | West Nile virus | Avian carcasses | Nemeth et al. (2009) | |

| Pig bristles | None reported | ||||

| Horns, horn products, hooves and hoof products | Non‐enveloped RNA | Picornaviridae | Senecavirus A | Pigs, cattle | Niedbalski and Fitzner (2019) |

viral hazards for which thermal inactivation kinetics or other relevant information was already available (REFRESH study: Hayrapetyan et al., 2019).

2.3. Thermal and chemical inactivation (AQ2, AQ4, AQ5)

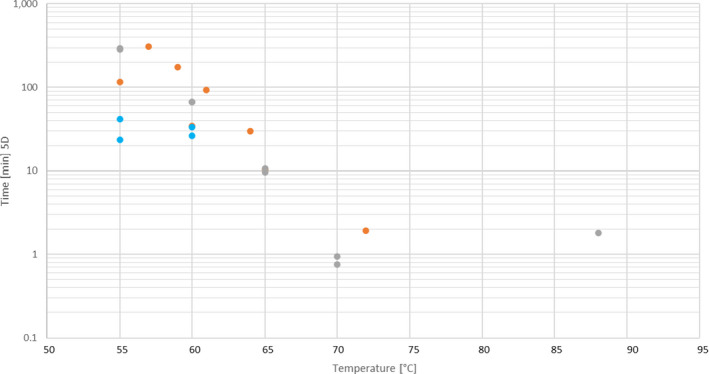

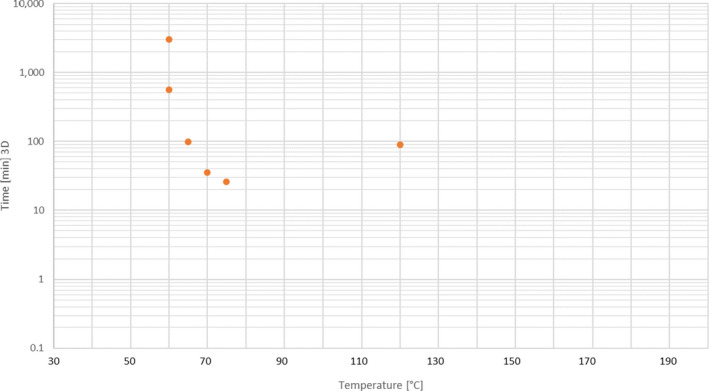

An extensive literature search was conducted to extract data from the scientific literature on thermal and chemical inactivation of E. faecalis and S. Senftenberg in the form of time/temperature/pH combinations in defined matrices (even if different from those in the mandate). Data on chemical inactivation of S. Senftenberg were extracted from this extensive literature review, whereas data on thermal inactivation of this bacteria were extracted from the review of studies on the thermal resistance of salmonellae executed by Doyle and Mazzotta (2000).

An extensive literature search was conducted to extract data from the scientific literature on thermal and chemical inactivation of the selected viruses in the form of time/temperature/pH combinations in defined matrices (even if different from the ones in the mandate). Out of the virus identified as hazards in the extensive literature search (ELS) described in Section 2.2 to address AQ3, only non‐enveloped viruses that may be intrinsically present in the materials were selected as the most resistant to thermal and other treatments for each group.

An ELS was conducted to extract data from the scientific literature on chemical inactivation of Ascaris spp. in the form of time/temperature/pH combinations in defined matrices (even if different from those in the mandate).

The description of these three ELS is detailed below.

The criterion for selection of references was experimental studies in which resistance parameters (D‐ and/or Z‐values) or the levels of reduction or inactivation of the selected bacteria, viruses or parasites (preferably measured in log10) had been measured after thermal and/or chemical treatment in matrices preferably similar to the ones included in the mandate. The database used was Scopus, Elsevier (English language, worldwide and not restricted in years).

The search strings were designed by combining the generic names of biological hazards (selected bacteria, viruses or parasites) AND (inactivation method) AND inactivation. The criteria for inclusion were if in the title, abstract or keywords, the specific name of the hazard (indicator microorganism or biological hazard) and inactivation/resistance keywords were mentioned. Details of the search strings can be found in Table A.1 of Annex A.

Table C.1.

Summary of the rationale for the consensus of each combination, as recorded by the rapporteur

| Process | Summary of rationale as recorded by the rapporteur. |

|---|---|

| 1.1 Ash derived from incineration 850°C, > 2 s | Although the temperature of the process (850°C) is extremely high and the three indicators would be reduced to the desired level, there is some uncertainty left considering that the duration of 2 seconds may not be sufficient, the starting concentration is unknown and there may be some protecting material. |

| 1.2 Ash derived from incineration1,100°C, > 0.2 s | The temperature of the process (1,100°C) is higher than in 1.2 but with shorter time (0.2 s) and it is believed that the three indicators would be reduced to the desired level. Still, the starting concentration is unknown and there may be some protecting material leaving some uncertainty. |

| 2.1 Glycerine derived from the production of biodiesel and renewable fuels Category 2 materials 133°C, 20 min, 3 bar (Method 1) + pH < 1/72°C/> 2 h (esterification) + pH ˜ 14/35°C to 50°C/> 15 min (transesterification) | The thermal treatment (133°C, 20 min, 3 bar) alone would give significant reductions of the three indicators as inactivation of non‐spore forming bacteria at temperatures > 100°C should be achieved in a few seconds. There is a sequence of this thermal with chemical treatments (esterification and transesterification) that is expected to give further reductions. There is some uncertainty left as the material is pure fat in which it is more difficult to reduce the three indicators. |

| 2.2 Glycerine derived from the production of biodiesel and renewable fuels Category 3 materials 80°C, 120 min (Method 5 (a)) + pH ˜ 14/35°C to 50°C/> 15 min (transesterification) | As in 2.1, it needs to be considered that the material is pure fat. The probability ranges of E. faecalis and S. Senftenberg are considered the same. The range is quite broad reflecting the uncertainty on whether there is a difference or not; In case there was a difference, there would be a bit lower confidence for S. Senftenberg than for E. faecalis. The probability for the Parvovirus is lower compared to the bacterial indicators as the thermal treatment may be effective but there is no clear indication on the effect of the pH on the virus inactivation during the transesterification step. |

| 2.3 Glycerine derived from the production of biodiesel and renewable fuels Category 3 materials 100°C 60 min (Method 5(b)) + pH ˜ 14/35°C to 50°C/> 15 min (transesterification) | The rationale is the same as in 2.2. The probability range has been increased compared to 2.2 for the bacterial indicators and the Parvovirus because of the higher temperature used in this process for which there is more evidence of inactivation. |

| 3.1 Other products of materials derived from the production of biodiesel and renewable fuels Category 2 materials Method 1: 133°C, 20 min, 3 bar | This is the same process as in 2.1 but without transesterification and with a different material (but with high fat content). There is some evidence that the treatment would be less effective on S. Senftenberg compared to E. faecalis. However, this difference is not big enough to have a different probability range (i.e. E. faecalis a bit higher and S. Senftenberg a bit lower). For the Parvovirus, the range was considered the same as for the bacteria considering the evidence on thermal inactivation. |

| 3.2 Other products of materials derived from the production of biodiesel and renewable fuels Category 3 materials Method 5(a): 80°C, 120 min | The process is the same as in 3.1, but with lower temperature and higher time. It is also the same process as in 2.2 but without transesterification and with a different material (but with high fat content). The evidence on thermal inactivation indicates that the thermal treatment is not sufficient to inactivate S. Senftenberg. Compared to 3.1, the difference between S. Senftenberg and E. faecalis is more obvious as there is a larger range here. For the Parvovirus there is more uncertainty here based on the available evidence on thermal inactivation. |

| 3.3 Other products of materials derived from the production of biodiesel and renewable fuels Category 3 materials Method 5(b): 100°C, 60 min | The rationale is the same as in 3.2. The lower bound of the probability range has been increased compared to 3.2 for the bacteria and the Parvovirus because of the higher temperature used in this process in which there is more evidence for inactivation. The difference between the bacterial indicators is again more obvious as the range is larger. |

| 4.1 Hides and skins Limed hides pH 12–13, 8 h | There is less evidence about the inactivation for this process and there is uncertainty about the level of heat released through the liming process which is dependent on the lime concentration used (concentration or temperature are not mentioned in legislation). The desired reduction may not be achieved using the pH alone also considering that the matrix has a very low water content. For Ascaris the time needed for inactivation (as in studies) is much longer. For the viruses (Papillomavirus, Picornavirus, Reovirus), the reduction is more difficult to achieve compared to bacterial indicators, but easier compared to Ascaris. |

| 4.2 Hides and skins pH ˜ 12, > 8 h + pH < 3, 16 h | Compared to 4.1, the matrix is the same, but a treatment has been added (pH < 3 16 h) and the alkaline treatment lasts longer. The upper bound has been increased for the bacteria considering the acid treatment. There is little information on the inactivation of Ascaris eggs at acidic pH which may add an additional reduction. For the viruses, there is less information available than for bacterial indicators but there is some evidence for reductions at acidic pH values. |

| 5.1 Wool and hair pH > 12–13, 5 min | There are no data available for such short alkaline processes which may be too short to achieve the desired level of reduction. The temperature will not rise because the processing time is short. Ascaris eggs are likely more difficult to reduce by alkaline processes than the bacterial indicators and viruses. |

| 5.2 Wool and hair pH > 12–13, 60 min | As the treatment time is longer compared to 5.1, both the lower and upper ranges have been increased. |

| 6. Feather and down 100°C for at least 30 min | The treatment is made with steam and after washing, which would increase the water content of the matrix. The temperature/time combination would be sufficient to inactivate the bacterial indicators. For the viruses (Anellovirus, Circovirus), there is higher uncertainty than for bacteria. |

| 7.1 Pig bristles 100°C in water, 5 min | The treatment is made with boiling water, which would increase the water content of the matrix. The time is shorter compared to 6, and both the lower and upper ranges have been decreased. For parvoviruses, contradictory data are available around 100°C. |

| 7.2 Pig bristles 100°C in water, 60 min | The treatment is at the same temperature as 7.1 but for longer time and therefore the lower and upper ranges have been increased. |

| 8. Horns, horn products, hooves and hoof products 80°C 1 h | The material is rich in protein and with a very low‐fat content and lower water activity than other materials, which led to an increase of the uncertainty. Picornaviridae are less resistant than Parvoviridae and the evidence mainly supports that the desired reduction would be achieved. |

The selection of studies was made by screening the title and abstract of the references extracted following the application of the search strings. The list of references was presented in tabular format in a template containing the following fields: Authors, Title, Year, DOI, Link and Abstract. The list of references for each indicator microorganism or biological hazard was screened by WG members and EFSA staff. For each reference, one of the following three options was assigned: ‘Yes’, when it was possible to extract inactivation data by looking at the paper in full; ‘Doubtful’, when it may be useful in a second round to look more in depth; ‘No’ when the reference was to be discarded. References in category Yes were retrieved and full papers were reviewed, splitting them into two groups: those with/without relevant data to be extracted. Data from papers with relevant data were transferred to a tabular template including the preselected set of fields. Review of doubtful references was left at the discretion of the reviewer.

Data extracted on thermal inactivation were presented in tabular format using a template with the following fields: hazard (virus, etc.), matrix/substrate, initial load, treatment, temperature (°C), time (min), level of inactivation, D‐value (min) and reference. Data extracted on chemical inactivation were presented in tabular format using a template with the following fields: matrix/substrate, indicator microorganism/biological hazard, initial load, treatment, level of inactivation and reference.

The data obtained from the literature were considered by the WG to evaluate, using EKE, the certainty on whether the required level of reduction is achieved for the indicator microorganisms and/or biological hazards by the standard processing parameters identified in AQ1 and for each of the materials.

2.4. Uncertainty analysis and expert knowledge elicitation

Based on the EFSA guidance on Uncertainty Analysis in Scientific Assessments (EFSA Scientific Committee, 2018a) and the scientific opinion on the principles and methods behind EFSA's Guidance on Uncertainty Analysis in Scientific Assessment (EFSA Scientific Committee, 2018b), the sources of uncertainty associated with the available data were summarised in tabular format (Table 12 in Section 4), describing also the cause of the uncertainty. The impact of the uncertainty on the level of inactivation of the selected indicator microorganisms and biological hazards was described, without specifying in which of the combinations of material, process and hazard, the over‐/underestimation would occur.

An EKE was performed to answer AQ2, AQ4 and AQ5, based on the collected evidence and indicated uncertainties. The EKE questions were specified as follows:

What is the probability that a 5 log10 reduction of E. faecalis is achieved, in more than 99% of cases, by application of the relevant process/es, assuming that the process(es) is/are performed as prescribed and that the indicated process conditions are achieved?

What is the probability that a 5 log10 reduction of S. Senftenberg (775W, H2S negative) is achieved, in more than 99% of cases, by application of the relevant process/es, assuming that the process/es is/are performed as prescribed and that the indicated process conditions are achieved?

What is the probability that a 3 log10 reduction of parvovirus or the identified most resistant viruses is achieved, in more than 99% of cases, by application of the relevant process/es, assuming that the process/es is/are performed as prescribed and that the indicated process conditions are achieved?

What is the probability that a 3 log10 reduction of eggs of Ascaris sp. is achieved, in more than 99% of cases, by application of the relevant chemical process/es, assuming that the process/es is/are performed as prescribed and that the indicated process conditions are achieved?

In these questions, the phrase ‘in more than 99% of cases’ refers to the potential variation in the performance of the relevant process/es. As the process/es is/are well defined, this variation is considered to be small. The ‘probability’ refers to the certainty that the log10 reduction is achieved if this well‐defined process is performed.

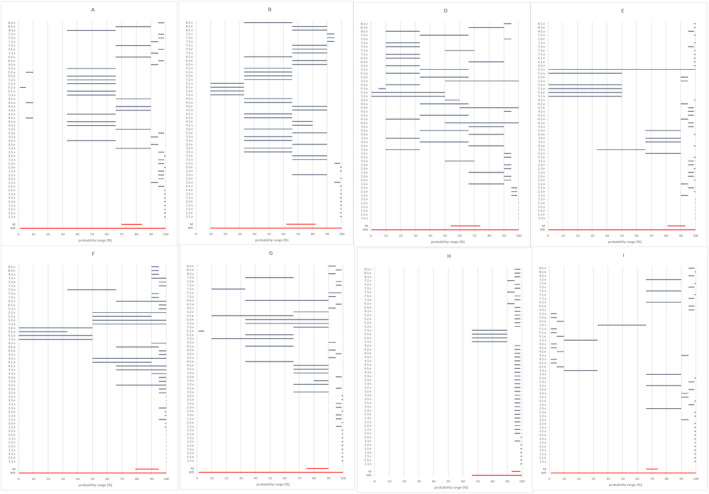

The EKE consisted of two steps: individual judgements and consensus judgements. In Step 1, the experts provided individual judgements for each of the 52 combinations of material/process/hazard by considering them separately, taking into account the version of the draft opinion at the beginning of the process with the raw data on thermal and chemical inactivation of the indicators, the description of the processes, the integration of the evidence and the uncertainty table, as well as the personal expertise and assessment of the uncertainties involved. In Step 2, during an open session, the experts were asked to consider what a rational impartial observer (RIO) would judge, having considered the evidence, uncertainties, the individual judgements and having heard the discussion maintained by the experts. As the starting point for the discussions, a potential consensus probability range was proposed by the facilitator, based on the mean of the median estimates of all the individual ranges. The objective of Step 2 was to reach consensus on the probability ranges that were considered to best represent the uncertainty on whether the indicated log10 reductions are achieved with the standard processes for the different materials. Detailed information on the EKE can be found in Appendix C and in Table A.1 of Annex A.

3. Assessment

3.1. Introduction

3.1.2 Category 2 and 3 animal by‐products and derived products

Regulation (EC) No 1069/2009 defines ‘animal by‐products’ as ‘entire bodies or parts of animals, products of animal origin or other products obtained from animals, which are not intended for human consumption, including oocytes, embryos and semen; and ‘derived products’ as products obtained from one or more treatments, transformations or steps of processing of animal by‐products.’

The use or fate of ABP depends on their risk classification in three different categories: (i) Category 1 material consists mainly of material that is considered at transmissible spongiform encephalopathy (TSE) risk, and as such represents the highest risk material; (ii) category 2 material includes fallen stock, manure and gastrointestinal contents; (iii) Category 3 materials are considered of a lower risk level and include parts of animals that have been considered fit for human consumption at the slaughterhouse, but that are not intended for human consumption for production or commercial reasons (e.g. trimmings of carcasses, consumer rejection to certain organs, etc.).

More specifically, and within the framework of this assessment, Article 9 of Regulation (EC) No 1069/2009 lists as Category 2 materials the following ABP:

manure, non‐mineralised guano and digestive tract content;

-

animal by‐products collected during the treatment of waste water required by implementing rules adopted under point (c) of the first paragraph of Article 27:

from establishments or plants processing Category 2 material;

or from slaughterhouses other than those covered by Article 8(e);

animal by‐products containing residues of authorised substances or contaminants exceeding the permitted levels as referred to in Article 15(3) of Directive 96/23/EC;

products of animal origin which have been declared unfit for human consumption due to the presence of foreign bodies in those products;

-

products of animal origin, other than Category 1 material, that are:

imported or introduced from a third country and fail to comply with Community veterinary legislation for their import or introduction into the Community except where Community legislation allows their import or introduction subject to specific restrictions or their return to the third country; or

dispatched to another Member State and fail to comply with requirements laid down or authorised by Community legislation except where they are returned with the authorisation of the competent authority of the Member State of origin;

-

animals and parts of animals, other than those referred to in Article 8 or Article 10,

that died other than by being slaughtered or killed for human consumption, including animals killed for disease control purposes;

foetuses;

oocytes, embryos and semen which are not destined for breeding purposes; and

dead‐in-shell poultry;

mixtures of Category 2 material with Category 3 material;

animal by‐products other than Category 1 material or Category 3 material (Article 9, Regulation (EC) No 1069/2009).

In relation to Category 3 materials, Article 10 lists among them the following ABP relevant to this mandate:

carcases and parts of animals slaughtered or, in the case of game, bodies or parts of animals killed, and which are fit for human consumption in accordance with Community legislation, but are not intended for human consumption for commercial reasons;

-

carcasses and the following parts originating either from animals that have been slaughtered in a slaughterhouse and were considered fit for slaughter for human consumption following an ante‐mortem inspection or bodies and the following parts of animals from game killed for human consumption in accordance with Community legislation:

carcasses or bodies and parts of animals which are rejected as unfit for human consumption in accordance with Community legislation, but which did not show any signs of disease communicable to humans or animals

heads of poultry;

-

hides and skins, including trimmings and splitting thereof, horns and feet, including the phalanges and the carpus and metacarpus bones, tarsus and metatarsus bones, of:

-

–

animals, other than ruminants requiring TSE testing, and

-

–

ruminants which have been tested with a negative result in accordance with Article 6(1) of Regulation (EC) No 999/2001;

-

–

pig bristles

feathers

-

c

animal by‐products from poultry and lagomorphs slaughtered on the farm as referred to in Article 1(3)(d) of Regulation (EC) No 853/2004, which did not show any signs of disease communicable to humans or animals;

-

d

blood of animals which did not show any signs of disease communicable through blood to humans or animals obtained from the following animals that have been slaughtered in a slaugh−terhouse after having been considered fit for slaughter for human consumption following an ante‐mortem inspection in accordance with Community legislation:

animals other than ruminants requiring TSE testing; and

ruminants which have been tested with a negative result in accordance with Article 6(1) of Regulation (EC) No 999/2001;

-

e

animal by‐products arising from the production of products intended for human consumption, including degreased bones, greaves and centrifuge or separator sludge from milk processing;

-

f

products of animal origin, or foodstuffs containing products of animal origin, which are no longer intended for human consumption for commercial reasons or due to problems of manu−facturing or packaging defects or other defects from which no risk to public or animal health arise;

-

g

petfood and feeding stuffs of animal origin, or feeding stuffs containing animal by‐products or derived products, which are no longer intended for feeding for commercial reasons or due to problems of manufacturing or packaging defects or other defects from which no risk to public or animal health arises;

-

h

blood, placenta, wool, feathers, hair, horns, hoof cuts and raw milk originating from live animals that did not show any signs of disease communicable through that product to humans or animals;

-

i

aquatic animals, and parts of such animals, except sea mammals, which did not show any signs of disease communicable to humans or animals;

-

j

animal by‐products from aquatic animals originating from establishments or plants manufacturing products for human consumption;

-

k

the following material originating from animals which did not show any signs of disease communicable through that material to humans or animals:

shells from shellfish with soft tissue or flesh;

the following originating from terrestrial animals: — hatchery by‐products, — eggs, — egg by‐products, including egg shells,

day‐old chicks killed for commercial reasons;

-

l

aquatic and terrestrial invertebrates other than species pathogenic to humans or animals;

-

m

animals and parts thereof of the zoological orders of Rodentia and Lagomorpha, except Category 1 material as referred to in Article 8(a)(iii), (iv) and (v) and Category 2 material as referred to in Article 9(a) to (g);

-

n

hides and skins, hooves, feathers, wool, horns, hair and fur originating from dead animals that did not show any signs of disease communicable through that product to humans or animals, other than those referred to in point (b) of this Article;

-

o

adipose tissue from animals which did not show any signs of disease communicable through that material to humans or animals, which were slaughtered in a slaughterhouse and which were considered fit for slaughter for human consumption following an ante‐mortem inspection in accordance with Community legislation;

-

p

catering waste other than as referred to in Article 8(f).

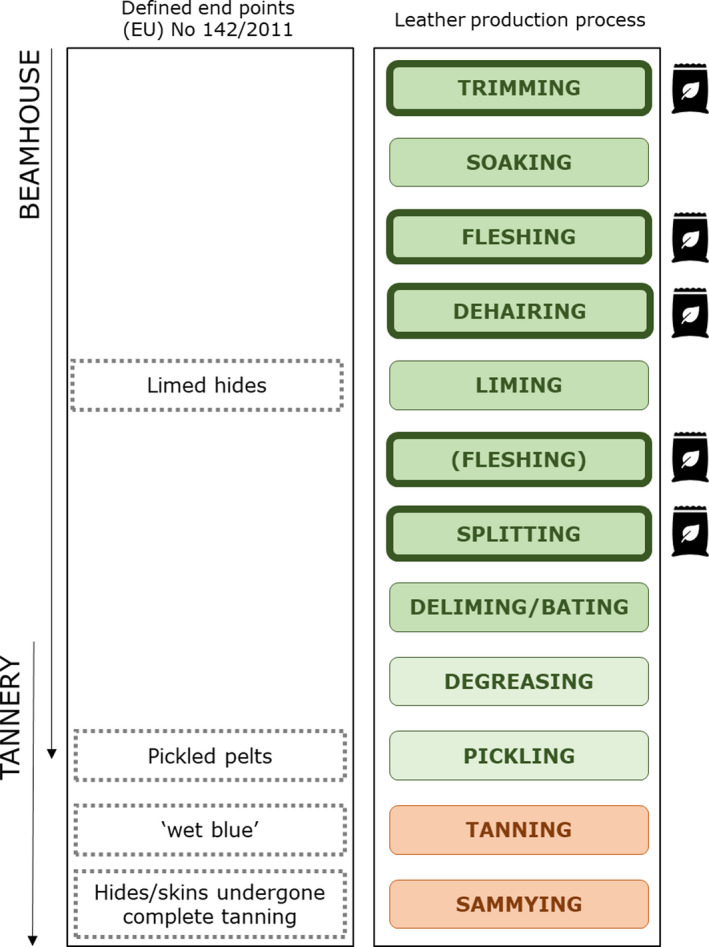

3.1.2 End points in the manufacturing chain

Article 5(2) of Regulation (EC) 1069/2009 states that: ‘for derived products referred to in articles 32 (organic fertilisers and soil improvers), 35 (pet food) and 36 (other derived products), which no longer pose any significant risk to public or animal health, an end point in the manufacturing chain may be determined, beyond which they are no longer subject to the requirements of this Regulation’.

Article 32 refers to organic fertilisers and soil improvers which may be placed on the market and used under certain conditions. In addition, digestate, the by‐product from the transformation of food waste, sludge, animal slurry, grease‐trap waste, etc. into biogas or compost may be placed on the market and used as organic fertiliser or soil improver.

Article 35 refers to pet food under certain conditions.

Article 36 refers to other derived products than the products referred to in Articles 31, 32, 33 and 35. Those derived products may subsequently be placed on the market without restrictions under Regulation (EC) 1069/2009 and shall no longer be subject to official controls in accordance with Regulation (EC) 1069/2009.

The legal context of this mandate is specified in point 4 of Article 5, as amended by Regulation (EU) 2019/1009, which states that: ‘within six months after 15 July 2019, the Commission shall initiate a first assessment of derived products referred to in Article 32 that are already widely used in the Union as organic fertilisers and soil improvers. This assessment shall cover at least the following products: meat meal, bone meal, meat‐and-bone meal, hydrolysed proteins of Category 3 materials, processed manure, compost, biogas digestion residues, feather meal, glycerine and other products of Category 2 or 3 materials derived from the production of biodiesel and renewable fuels, as well as petfood, feed and dog chews that have been refused for commercial reasons or technical failures, and derived products from blood of animals, hides and skins, hoofs and horns, guano of bats and birds, wool and hair, feathers and downs, and pig bristles. Where the assessment concludes that those derived products no longer pose any significant risk to public or animal health, the Commission shall determine an end point in the manufacturing chain pursuant to paragraph 2 of this Article without undue delay and in any case no later than six months after the assessment is finalised.’

Commission Regulation (EU) No 142/201121 lays down implementing measures: (a) for the public and animal health rules for animal by‐products and derived products laid down in Regulation (EC) No 1069/2009; (b) concerning certain samples and items exempt from veterinary checks at border inspection posts as provided for in Article 16(1)(e) and (f) of Directive 97/78/EC. This EU regulation provides requirements regarding the processing and transformation of ABP into different derived materials. In relation to the declaration of end points, there are a number of derived products that have been declared end points in the manufacturing chain according to this regulation. Thus, article 3 of Commission Regulation (EU) 142/2011 lists the derived products that may be placed on the market, other than imported, without restrictions, as provided in Article 5(2) of Regulation (EC) No 1069/2009:

biodiesel which fulfils the requirements for the disposal and use of derived products set out in point 2(b) of Section 3 of Chapter IV of Annex IV;

processed petfood which fulfils the specific requirements for processed petfood set out in point 7(a) of Chapter II of Annex XIII;

dog chews which fulfil the specific requirements for dog chews set out in point 7(b) of Chapter II of Annex XIII;

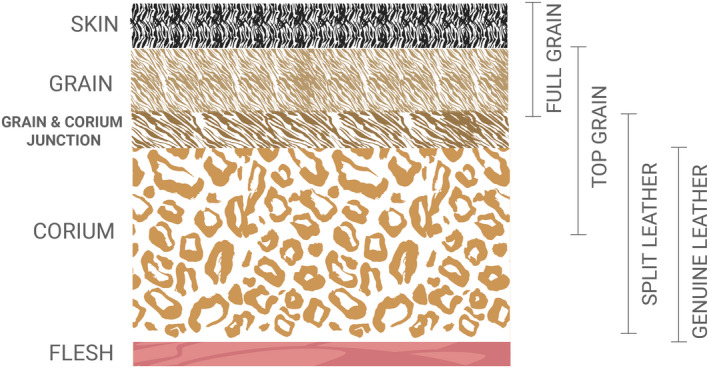

hides and skins of ungulates which fulfil the specific requirements for the end point for those products set out in point C of Chapter V of Annex XIII;

wool and hair, which fulfil the specific requirements for the end point for those products set out in point B of Chapter VII of Annex XIII;

feathers and down, which fulfil the specific requirements for the end point for those products set out in point C of Chapter VII of Annex XIII;

fur which fulfils the special requirements for the end point for that product set out in Chapter VIII of Annex XIII;

fish oil for the production of medicinal products which fulfils the special requirements for the end point for that product set out in Chapter XIII of Annex XIII;

gasoline and fuels which fulfil the specific requirements for products from the multi‐step catalytic process for the production of renewable fuels set out in point 2(c) of Section 3 of Chapter IV of Annex IV;

oleochemical products derived from rendered fats and which fulfil the requirements set out in Chapter XI of Annex XIII;

renewable diesel, renewable jet fuel, renewable propane and renewable gasoline which fulfil the specific requirements for products from the multi‐step catalytic hydro‐treatment for the production of renewable fuels set out in point 2(f) of Section 3 of Chapter IV of Annex IV.

3.2. Description of the materials included in the mandate

3.2.1. Ash derived from incineration, co‐incineration and combustion

According to the ABP EU Regulations, incineration can be defined as the disposal of ABP or derived products as waste, in an incineration plant, as defined in point 4 of Article 3 of Directive 2000/76/EC22. Co‐incineration means the recovery or disposal of ABP or derived products, if they are waste, in a co‐incineration plant. Finally, combustion means a process involving the oxidation of fuel in order to use the energy value of the ABP or derived products, if they are not waste.

According to Regulation (EC) 1069/2009, ABP, either categorised as Cat. 1, Cat. 2 or Cat. 3 material, can be disposed of as a waste by incineration or co‐incineration directly without prior processing or following processing, by pressure sterilisation, if the competent authority requires so, and permanent marking of the resulting material, or used as a fuel for combustion with or without prior processing.

The process can take place in open‐air, fixed‐facility or air‐curtain systems. Open‐air systems include the burning of carcasses or other ABP on combustible heaps known as pyres. Material requirements for open‐air burning include straw or hay, untreated timbers, kindling wood, coal and diesel fuel. Fixed‐facility systems include (a) small on‐farm incinerators, (b) small and large incineration facilities, (c) crematoria and (d) power plant incinerators. Fixed‐facility systems are wholly contained and, usually, highly controlled. They are typically fuelled by diesel, natural gas or propane. Newer designs of fixed‐facility systems are fitted with afterburner chambers designed to completely burn hydrocarbon gases and particulate matter exiting from the main combustion chamber. In air‐curtain systems, large‐capacity fans, driven by diesel engines, deliver high‐velocity air down into either a metal refractory box or burn pit (trench). Air‐curtain systems vary in size according to the amount of material to be incinerated. Materials needed for air‐curtain systems include wood (preferably pallets) and fuel (e.g., diesel fuel) for both the fire and the air‐curtain fan. Unlike fixed‐facility systems, air‐curtain systems are not wholly contained and are at the mercy of many variable factors (e.g. human operation, the weather, local community preferences, etc.) (National Agricultural Biosecurity Center, 2004).

According to Annex III, Chapter 1, Section 2 of Commission Regulation (EU) No 142/2011, incineration or co‐incineration plants shall be designed, equipped, built and operated in such a way that the gas resulting from the process is raised in a controlled and homogeneous fashion, even under the most unfavourable conditions, to a temperature of 850°C for at least 2 s or to a temperature of 1,100°C for 0.2 s, as measured near the inner wall or at another representative point of the chamber where the incineration or the co‐incineration is carried out, as authorised by the competent authority.

3.2.2. Glycerine derived from the production of biodiesel and renewable fuels

Biodiesel consists of mono‐alkyl esters of long‐chain fatty acids mostly produced from vegetable oils and animal fats. The total global production of biodiesel was approximately 35–45 million tonnes in 2019 (Flach et al., online). The European Union is the world's largest biodiesel producer and, in 2020, the European biodiesel industry produced in 2020 more than 15 million tonnes of biodiesel (75% of the total transport biofuels market on an energy basis).23

For biodiesel production, a fat fraction derived from ABP of all categories may be used. Such fats include extracted beef tallow, mutton tallow, pork lard and chicken fat (Sai Akhil and Alagumalai, 2019). Other fats used are those resulting from meat and the meat processing industry and those from recycling practices within the industrial cooking business. In 2019, 800,000 thousand tonnes (˜ 6% of total feedstock) corresponded to animal fats, and such amount has remained fairly constant since 2014 (Ramos et al., 2019).

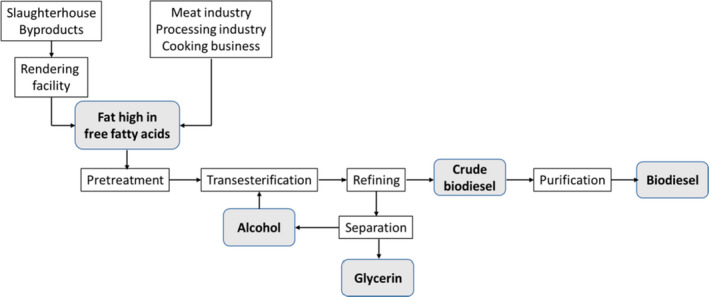

The major steps in the production of biodiesel from animal fat waste are shown in Figure 1. A pretreatment (e.g. heat drying, silica gel, treatment with calcium chloride or anhydrous sodium sulfate, neutralisation or separation) is needed because feedstocks usually contain a high proportion of free fatty acids (FFA) and water which reduce the yield of biodiesel and have to be removed (Gebremariam and Marchetti, 2018; Felizardo et al., 2006; Lee et al., 2002). Biodiesel is then produced through a transesterification reaction of a fat with a short‐chain alcohol (usually methanol) in the presence of a catalyst (such as an alkali, acid or enzyme) (Ma and Hanna, 1999; Ramadhas et al., 2005). Transesterification consists of the conversion of triacylglycerols to diacylglycerols, releasing one fatty acid. Diacylglycerols are then converted to monoacylglycerols, releasing a second fatty acid and, finally, monoacylglycerols are converted to glycerol, releasing a third fatty acid (Toldrá‐Reig et al., 2020). In industrial processing plants, ˜ 100 kg of fat react with 10 kg of methanol in the presence of an alkaline catalyst (i.e. sodium hydroxide or potassium hydroxide), to produce 100 kg of biodiesel and 10 kg of glycerine (US Department of Energy, 2020; Toldrá‐Reig et al., 2020).

Figure 1.

Major steps in the production of biodiesel from animal fat waste (Toldrá‐Reig et al., 2020)

An alternative process would be a two‐step transesterification, with the first step being an acid‐catalysed pretreatment to esterify the FFA and thus reduce their content, and the second step being the transesterification (Ramadhas et al., 2005).

Large amounts of glycerine (containing at least 95% glycerol) are generated during transesterification. Glycerine is purified, along with the removal of other impurities such as residual catalyst, unconverted fats and soap, through wet washing, based on water, dry washing, based on adsorption and ion exchange, or novel methods based on liquid–liquid extraction, deep eutectic solvents or membranes (Sander et al., 2018). Glycerine is a versatile and valuable chemical substance with many applications. In the conventional glycerine refining processes, the crude glycerine solution is initially treated with additional chemicals to remove any dissolved fatty acids or soaps, followed by processing in a higher temperature, high vacuum distillation unit. The condensed glycerine solution is further treated to remove traces of residual fatty acids, esters or other organic compounds (FAO, 2012).

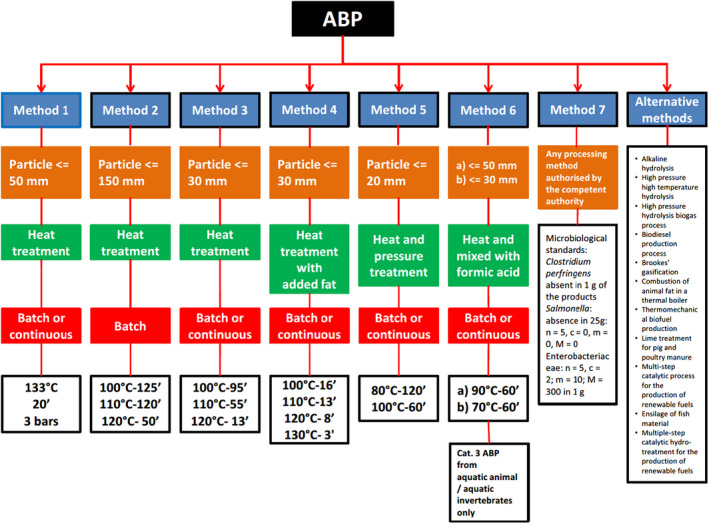

According to Annex IV, Chapter IV, Section 2 of Commission Regulation (EU) No 42/2011, biodiesel production shall be carried out according to the following processing standards:

-

Unless fish oil or rendered fat are used which have been produced in accordance with Sections VIII or XII of Annex III to Regulation (EC) No 853/2004, respectively, the fat fraction derived from animal by‐products must be first processed using:

in the case of Category 1 or 2 materials, processing method 1 (pressure sterilisation) as set out in Chapter III; and

in the case of Category 3 materials, any of the processing methods 1–5 or processing method 7 or, in the case of material derived from fish, processing methods 1–7 as set out in Chapter III;

-

The processed fat must then be processed further using one of the following methods:

a process whereby the processed fat must be separated from the protein and in the case of fat from ruminant origin, insoluble impurities in excess of 0.15% by weight must be removed, and the processed fat must be subsequently submitted to esterification and transesterification. However, esterfication is not required for processed fat derived from Category 3 material. For esterfication the pH must be reduced to less than 1 by adding sulphuric acid (H 2 SO 4 ) or an equivalent acid and the mixture must be heated to 72°C for at least two hours during which it must be intensely mixed. Transesterfication must be carried out by increasing the pH to about 14 with potassium hydroxide or with an equivalent base at 35°C to 50°C for at least 15 min. Transesterfication shall be carried out twice under the conditions described in this point using a new base solution. This process must be followed by refinement of the products including vacuum distillation at 150°C, leading to biodiesel;

a process using equivalent process parameters authorised by the competent authority.

3.2.3. Other materials derived from the production of biodiesel and renewable fuels