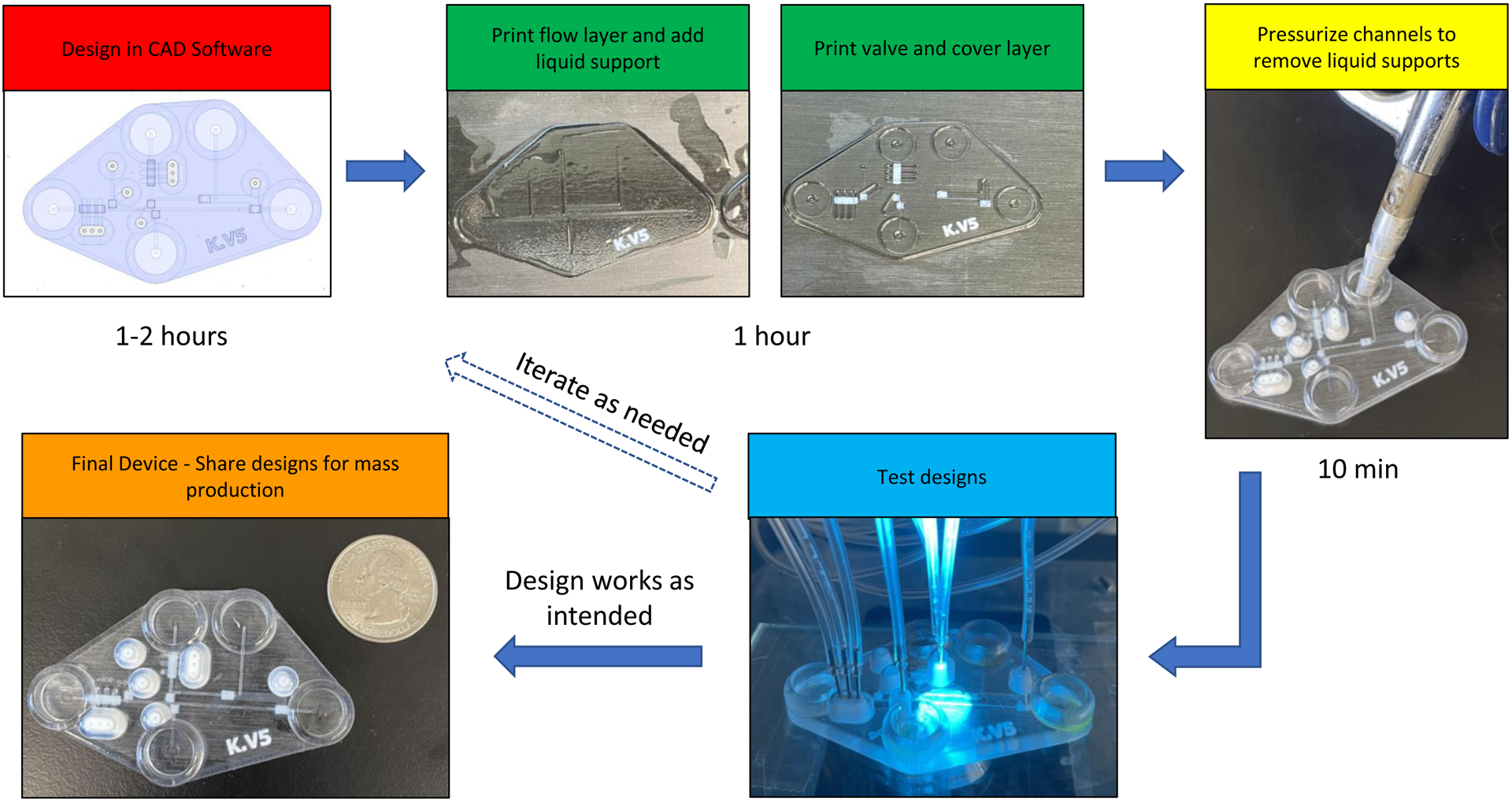

Figure 1.

Fabrication procedure used for the multi-layer, 3D printed devices used in these studies. Designs made in CAD are printed in several steps. A flow layer is printed first, liquid support is added, and separate prints for valving (containing white Agilus 30 where valving is needed) and cover layers are completed. Air is used to pressurize channels and remove liquid support. Designs are tested on a microscope and, if needed, designs can be changed in CAD and the process repeated in a relatively short time frame. The final device is down with respect to a US quarter.