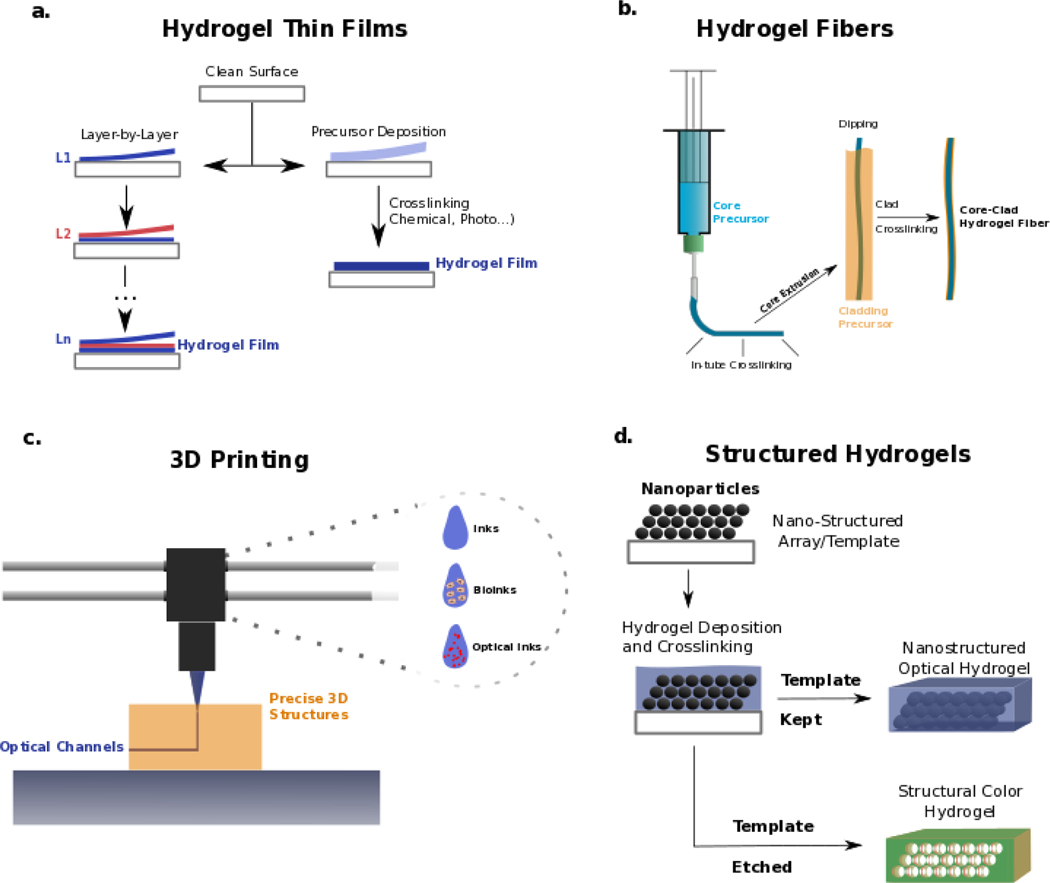

Figure 2: Fabrication techniques for obtaining hydrogel structures with relevant photonic properties.

a | Hydrogel thin films can be produced by deposition on a surface of either layer-by-layer molecular structures or single-step precursor deposition and crosslinking. b | Hydrogel fibers for optical applications are usually fabricated through UV crosslinking materials, structured in fiber-like shapes inside a tube, and then pushed out. These fibers can then be coated with a different hydrogel by, e.g., ionic crosslinking, as frequently pursued core-clad architectures. c | 3D printing techniques allow precise deposition of other materials and be further explored in the optical context. These techniques facilitate the fabrication of complex 3D structures where inks and bioinks are combined with novel types of optical inks that can interact with light differently in, e.g., optical channels within constructs. d | Structured hydrogels are frequently fabricated by depositing these materials within a nano-structured template, which can then be kept inside the hydrogel (e.g., spaced particles) to add further optical interactions (e.g., plasmonic resonance). Alternatively, these nanostructures can be etched out (by, e.g., thermal or chemical processes), leaving only their shape in the hydrogel, as used to obtain hydrogels with structural colors (i.e., the color given by the interaction of light with nanostructures and not by the presence of dyes)