Optimizationa.

| |||

|---|---|---|---|

| Entry | Deviation from the above | Temp., time | 5aa (%) |

| 1 | NiBr2·diglyme, THF | 45 °C, 4 h | 60c |

| 2 | NiBr2·diglyme, THF | 60 °C, 4 h | 92 |

| 3 | NiCl2, THF | 60 °C, 4 h | 29d |

| 4 | Ni(acac)2, THF | 60 °C, 4 h | 66 |

| 5 | NiBr2bpy, THF | 60 °C, 4 h | 21 |

| 6 | THF | 60 °C, 4 h | 86 |

| 7 | 20 mol% of CuI or CuCN | 60 °C, 4 h | 2 |

| 8 | bpy instead of dtbpy, THF | 60 °C, 4 h | 70d |

| 9 | TMEDA instead of dtbpy, THF | 60 °C, 4 h | 28d |

| 10 | dppe instead of dtbpy, THF | 60 °C, 4 h | 10 |

| 11 | Toluene | 60 °C, 4 h | 38 |

| 12 | None | 60 °C, 4 h | 95 |

| 13 | None | rt, 12 h | 90 |

| 14 | 5 mol% Ni(OAc)2·4H2O | rt, 12 h | 94 (86)f |

| 15 | 2 mol% Ni(OAc)2·4H2O | rt, 12 h | 52 |

| 16 | Ni(COD)2 (1.5 eq. 3a), THF | rt, 12 h | 95 |

| 17 | Without Ni(OAc)2·4H2O | rt, 12 h | 2 |

| 18 | Silylzinc from PhMe2SiLi | rt, 12 h | 23 |

| 19 | 1 eq. LiCl additive | rt, 12 h | 42 |

| 20 | 4.2 mmol of 2a | rt, 12 h | (80) |

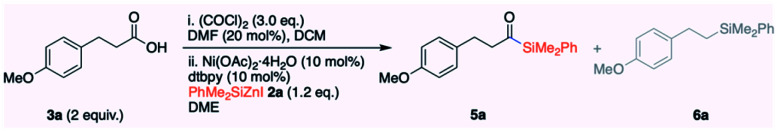

Reaction conditions: 0.39 mmol of 3a, 0.234 mmol of PhMe2SiZnI·TMEDA 2a (0.66 M in toluene), 0.0195 mmol of Ni(OAc)2·4H2O and dtbpy, 0.17 M (overall concentration). Isolated acid-chloride 4a was used in entries 1–7 and 17–19; in situ acid-chloride 4a was used in entries 8–16 and 20.

Yield determined by 1H NMR using 1,3,5-trimethoxy benzene as an internal standard.

1.3 eq. of PhMe2SiZnI.

Incomplete reaction; unreacted starting material was observed in the crude NMR.

1.0 eq. of PhMe2SiZnI was used.

Reactions were repeated at least 10 times throughout the project. DME: 1,2-dimethoxy ethane, yield in parentheses is isolated yield.