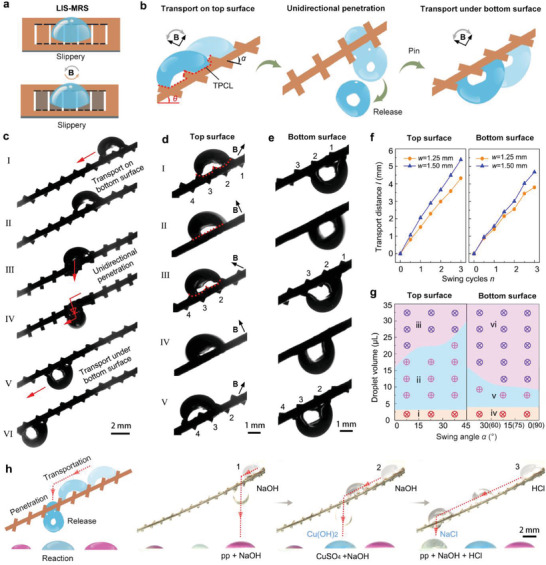

Figure 4.

Multifunctional droplet manipulation using a slant LIS‐MRS. a) Schematic of LIS‐MRS under magnetic actuation, whose surfaces are slippery. b) Schematic illustration of droplet transport on the top surface, penetration through interval of microblades, and transport under the bottom surface of the slant LIS‐MRS. c) The continuous droplet (7 µL) delivery process. It is composed of the droplet transport on the top surface, the droplet penetration, and the droplet transport under the bottom surface of a slant LIS‐MRS (w = 1.25 mm and s = 0.30 mm). d,e) Five typical stages of droplet transport on d) the top surface and e) the bottom surface of slant LIS‐MRS, respectively. f) The relationship between droplet transport distance, l, and swing cycles, n, of actuating field. The widths of microblades, w, are 1.25 and 1.5 mm, respectively. g) The phase diagram revealing droplet transport behaviors of slant LIS‐MRS under different swing angles α. The regions (i) and (iv) represent that small droplets get pinned on the surfaces. The regions (ii) and (v) represent that the droplet can be successfully transported along LIS‐MRS. The region (iii) represent that the large droplet cannot be transported along LIS‐MRS. The region (vi) represents the droplet may fall off from LIS‐MRS. h) Droplet (12 µL) distribution using LIS‐MRS (w = 1.50 mm and s = 0.30 mm) for programmable chemical reaction. Droplets were one by one transported to the targeted positions on LIS‐MRS and distributed to react with the underlying droplets.