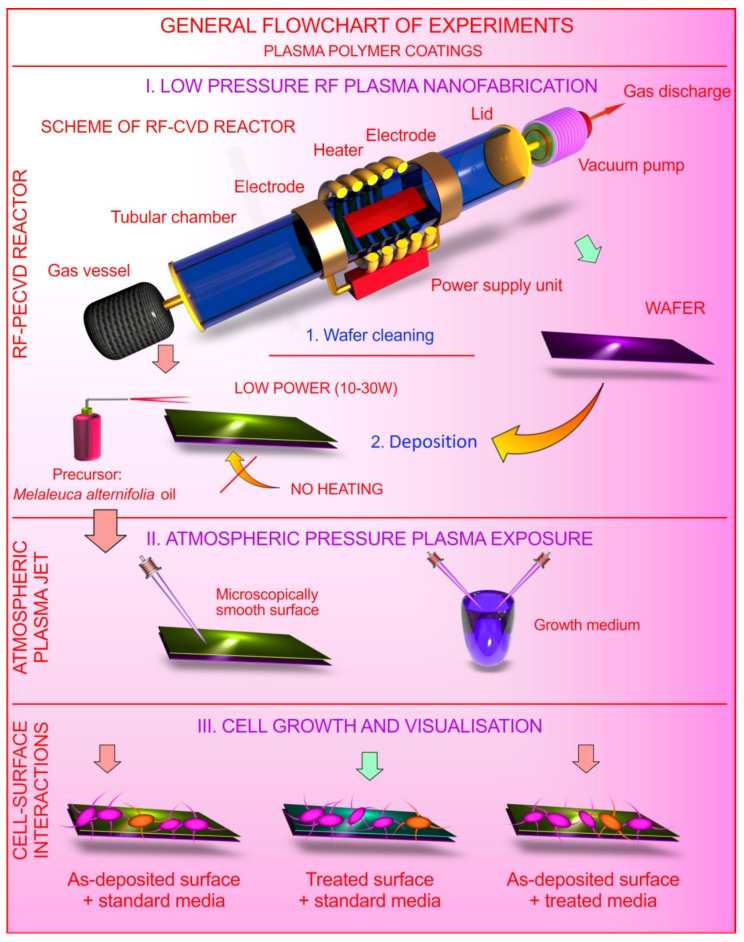

Figure 1.

Schematic depiction of the experimental process. (i) plasma polymers are fabricated from the vapors of the Melaleuca alternifolia essential oil that deposit as a thin solid coating over virtually any substrata, in this case polyethylene terephthalate (PET), at 10–30 W input radio frequency (RF) power (for mechanism of polymerization please refer to [19]); (ii) a subset of these samples was exposed to atmospheric pressure argon plasma for up to 60 s, and their properties characterized; separately, aqueous media were activated using a similar atmospheric pressure argon plasma treatment; (iii) cells were seeded onto the surfaces of treated and untreated (control) polymer coatings, and their attachment and viability were characterized; cells were also grown on the surfaces of control polymer coatings in the presence of plasma-activated culture media.