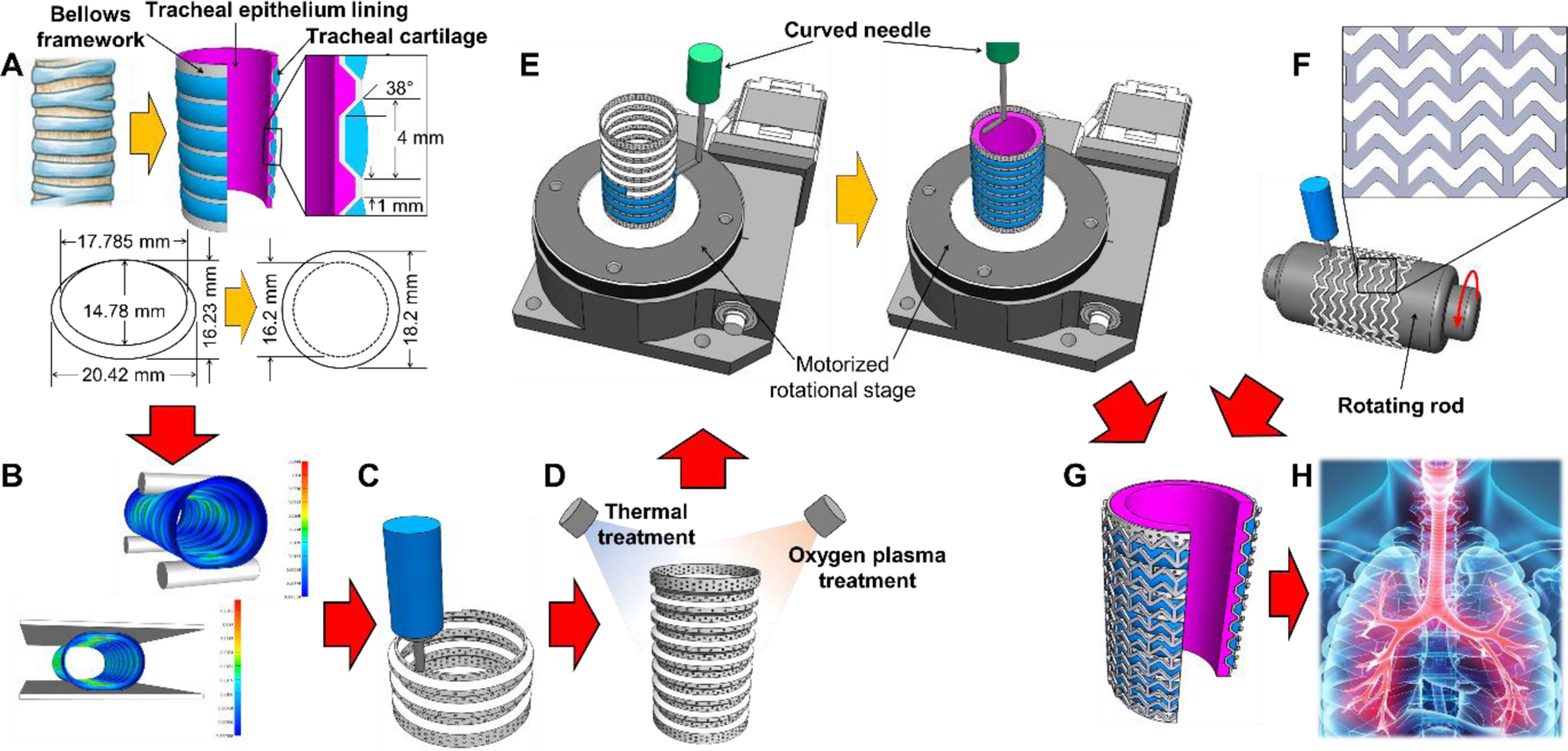

Fig. 1.

Schematics of the advanced two-step extrusion-based 3D bioprinting of the trachea-mimetic cellular construct of clinically relevant size. Step 1: (A) Design of the trachea-mimetic cellular construct based on canine tracheal anatomy. (B) FEA determining the effect of pore distribution on the mechanical behavior of the bellows framework. (C) Creation of porous bellows framework using a typical extrusion-based 3D printing. (D) Thermal/oxygen plasma treatments on the printed bellows framework. Step 2: (E) Rotational printing of separate cartilage rings and epithelial lining on the outer grooves and on the luminal surface of the bellows framework. (F) Creation of a SPTM for prevention of rapid resorption of cartilage rings in vivo. (G) Wrapping the trachea-mimetic cellular construct with a SPTM. (H) Implantation of the trachea-mimetic cellular construct wrapped with a SPTM into the circumferential tracheal defect for simultaneous regeneration of tracheal cartilage and epithelium.