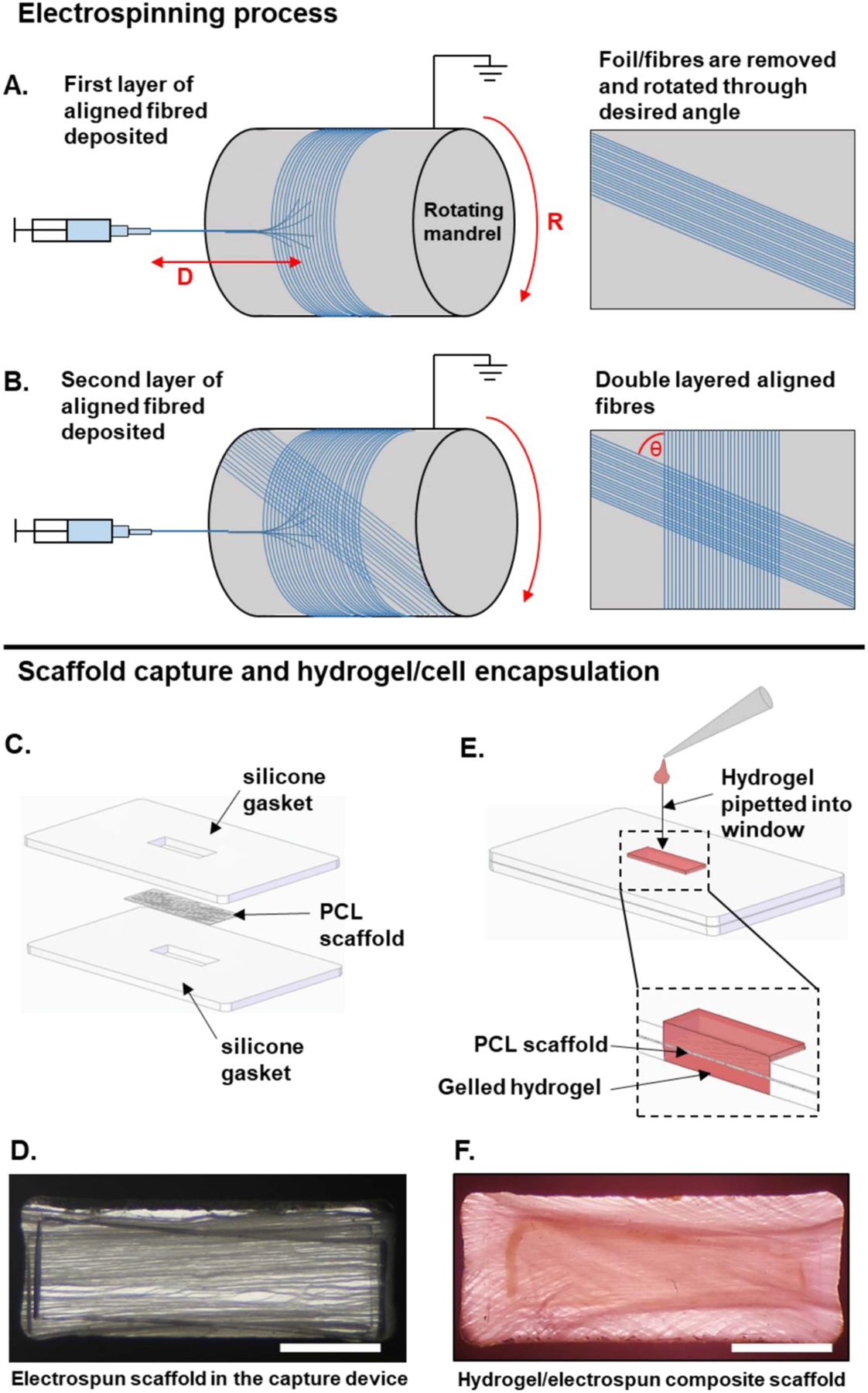

Figure 1.

Diagrammatic representation of the architected scaffolds’ manufacturing process. (A) and (B) represent the scaffold manufacturing method. (C)–(F) represent the intended use of the electrospun scaffold when encapsulated in a hydrogel. (A) PCL fibers are electrospun onto aluminum foil on a rotating mandrel. D = distance between needle tip and mandrel and R = rotational speed of mandrel. The fibers and foil are removed and rotated through the desired angle. (B) The second layer of fibers is then deposited on top the first layer. θ = fiber angle. (C) The electrospun scaffold is then placed between two silicone gaskets. The device is then placed onto the base of a non-treated 6-well polystyrene plate. (D) Final set up with fibers held in place in the capture device. (E) The collagen hydrogel containing NHDFs is then pipetted into the window which contains the PCL scaffold, creating a hydrogel/electrospun composite scaffold. (F) 60° PCL scaffold combined with a hydrogel. Scale bar = 2 mm.