Figure 1.

Process flow of flexible Al2O3/In2O3 FET-based conformal biosensors and their electrical characteristics

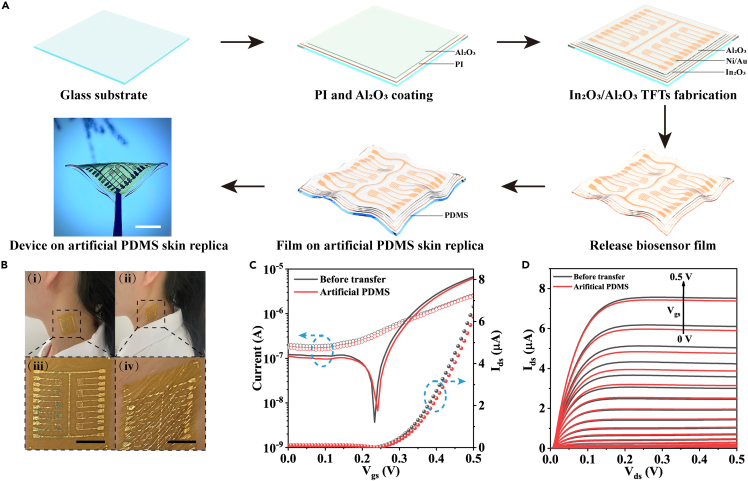

(A) Schematic showing the fabrication process of flexible bio-FETs. First, each glass substrate was coated with an ultrathin PI film, and a thin Al2O3 buffer layer was coated on the PI substrate. Next, In2O3 channel layer was spin-coated on PI film and baked at 300°C. Interdigitated source/drain electrodes of Ni/Au were patterned by shadow masks. Then Al2O3 precursor was spin coated on the UV-O3 treated In2O3 devices to serve as the passivation layer. The PI films with Al2O3/In2O3 bio-FET arrays were then delaminated from the rigid glass substrate and transferred to PDMS. The thin PI films with Al2O3/In2O3 bio-FET arrays could conformally attached to PDMS.

(B) Digital photos of flexible Al2O3/In2O3 bio-FET arrays conformally attached to human neck skin in flat (i) and stretched (ii) states. (iii-iv) Magnified views of the black dashed regions in (i) and (ii), respectively. Scale bars: 50 μm.

(C) Transfer characteristics of Al2O3/In2O3 bio-FETs on rigid glasses and soft PDMS substrates measured in 0.1× PBS solution, illustrating similar electrical performance before and after being transferred to PDMS substrates. Solid lines: Ids curves in logarithmic scales; solid circles: Ids curves in linear scales; open circles: Igs curves.

(D) Output curves of Al2O3/In2O3 bio-FETs on rigid glasses and flexible PDMS substrates, after transfer to soft PDMS substrates, the devices illustrated similar pinch-off characteristics under the Ag/AgCl liquid gating.