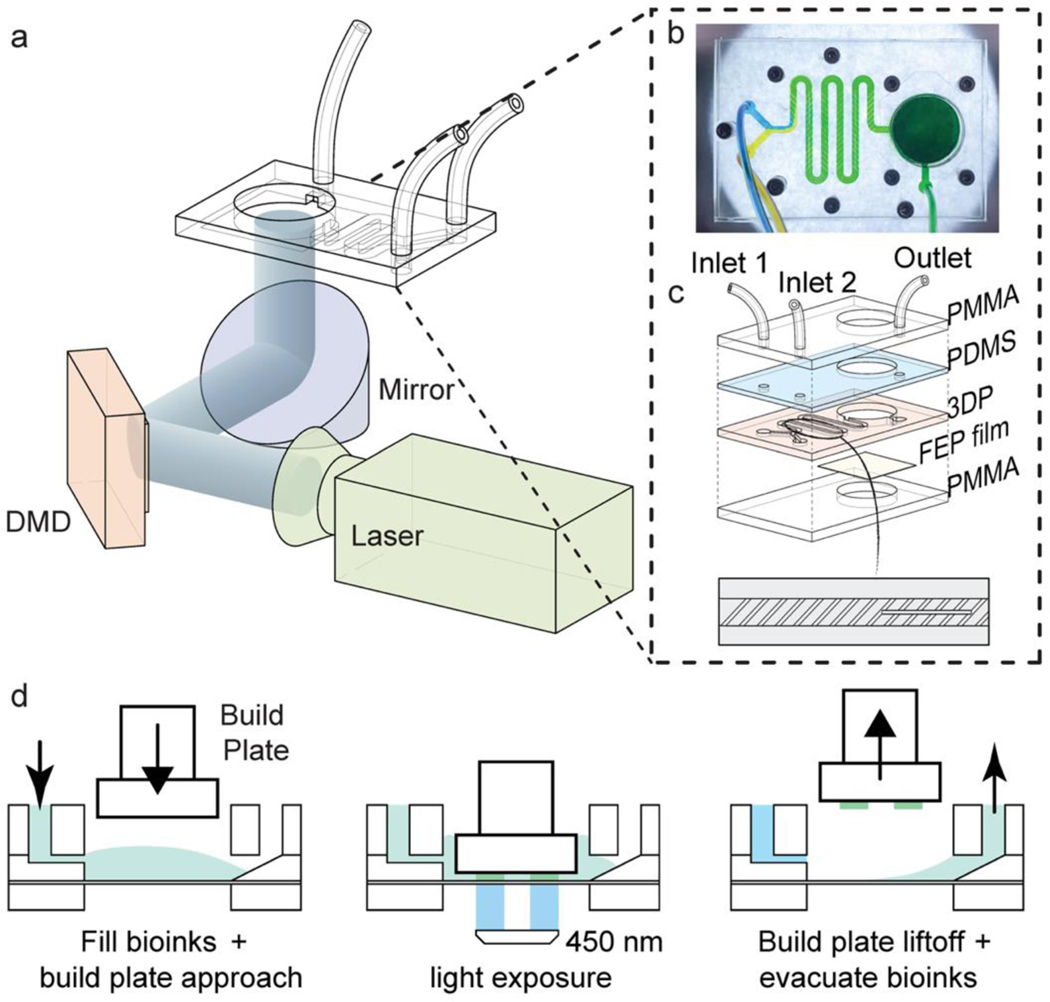

Figure 1.

The setup of the composable-gradient DLP (bio)printing platform and the (bio)printing workflow. (a) Schematic of the gradient DLP (bio)printer, combining the DLP (bio)printing system and the microfluidic mixing chip. (b) Photograph of the microfluidic mixing chip showing the blue and yellow colors mixed into the green, which is composed of a chaotic mixing microchannel and a (bio)ink vat. (c) Illustration showing the assembly of the microfluidic mixing chip bearing two inlets and one outlet. The bottom design presents the chaotic mixing microchannel containing slanted ribs and barriers. (d) The gradient DLP (bio)printing process for the continuous filling of the mixed (bio)ink, photocrosslinking, and evacuating the extra (bio)ink post-(bio)printing with each (bio)ink gradient.