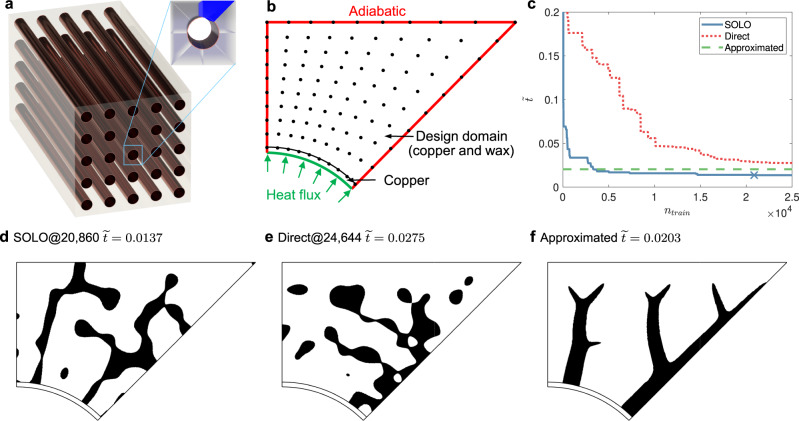

Fig. 6. Setup and results of a heat transfer enhancement problem with 10 × 10 design variables.

a Engineering background: a group of copper pipes is inserted in a phase change material. Because of symmetry, we only need to consider 1/8 of the unit cell (dark-blue area in the top right corner). b Problem setup: minimizing the time to charge the system with a given amount of heat, subject to heat flux, temperature, and volume constraints. The black dots denote locations of design variables. c Dimensionless charging time versus ntrain, the number of accumulated training samples. SOLO denotes our proposed method, where the cross “X” denotes the convergence point (presented in d). “Direct” denotes solving the problem directly by gradient descent. “Approximated” denotes simplifying this problem to a steady-state problem. d Optimized design obtained by SOLO. . e Optimized design obtained by “Direct”. ntrain = 24,644 and . f Optimized design obtained by “Approximated”. . In d–f black denotes ρ = 1 (copper) and white denotes ρ = 0 (wax). The SOLO result in d has islands isolated from major branches, while the “Approximated” result in f gives a connected structure. We try combining the islands to be part of major branches and find that the existence of isolated islands indeed reduces time, which demonstrates the powerfulness of our method.